Have you ever found yourself pondering on the intricacies of door hinges in industrial manufacturing settings? Well, it’s more intriguing than you might expect. A simple hinge can have an immense impact on the effectiveness and longevity of a large, heavy industrial door. After all, the role hinges play isn’t about being showy—it’s all about strength and reliability.

Interestingly, it’s not just about a specific hinge on a door that holds the most weight. It’s rather about the cohesive action of all the hinges that determines how well a door will function under heavy loads. In an industrial setting, the choice, placement, and number of hinges can drastically affect a door’s weight-bearing capacity.

Let’s dive deeper into this topic, peeling back the layers of hinges and their roles in bearing weight. Believe me, there’s a lot more to learn about this seemingly mundane topic.

How does hinge placement affect weight distribution?

In an industrial context, the distribution of weight across a door is fundamental. It’s not solely about which hinge bears the most weight, but rather where those hinges are located. Misplacement or a wrong number of hinges can lead to operational problems, even failures.

In fact, it’s common to see the bottom hinge carrying the majority of the door weight due to the gravitational pull. This doesn’t mean it’s the “strongest” hinge, but rather it’s the hinge most subject to stress. So, hinge placement plays a critical role in properly distributing the load of a door to ensure longevity and functionality.

What’s the impact of the number of hinges on weight-bearing capacity?

This is a frequently asked question, especiastlly in heavy-duty industrial settings where doors can weigh hundreds, even thousands of pounds. Here, the number of hinges on a door directly impacts its weight-bearing capacity.

Logically, more hinges mean better weight distribution. The increased number of contact points lessens the load on each individual hinge. Therefore, if you’re dealing with heavy industrial doors, adding more hinges can certainly help improve weight distribution and extend the lifespan of the door and its components.

Does the material of the hinge influence its strength?

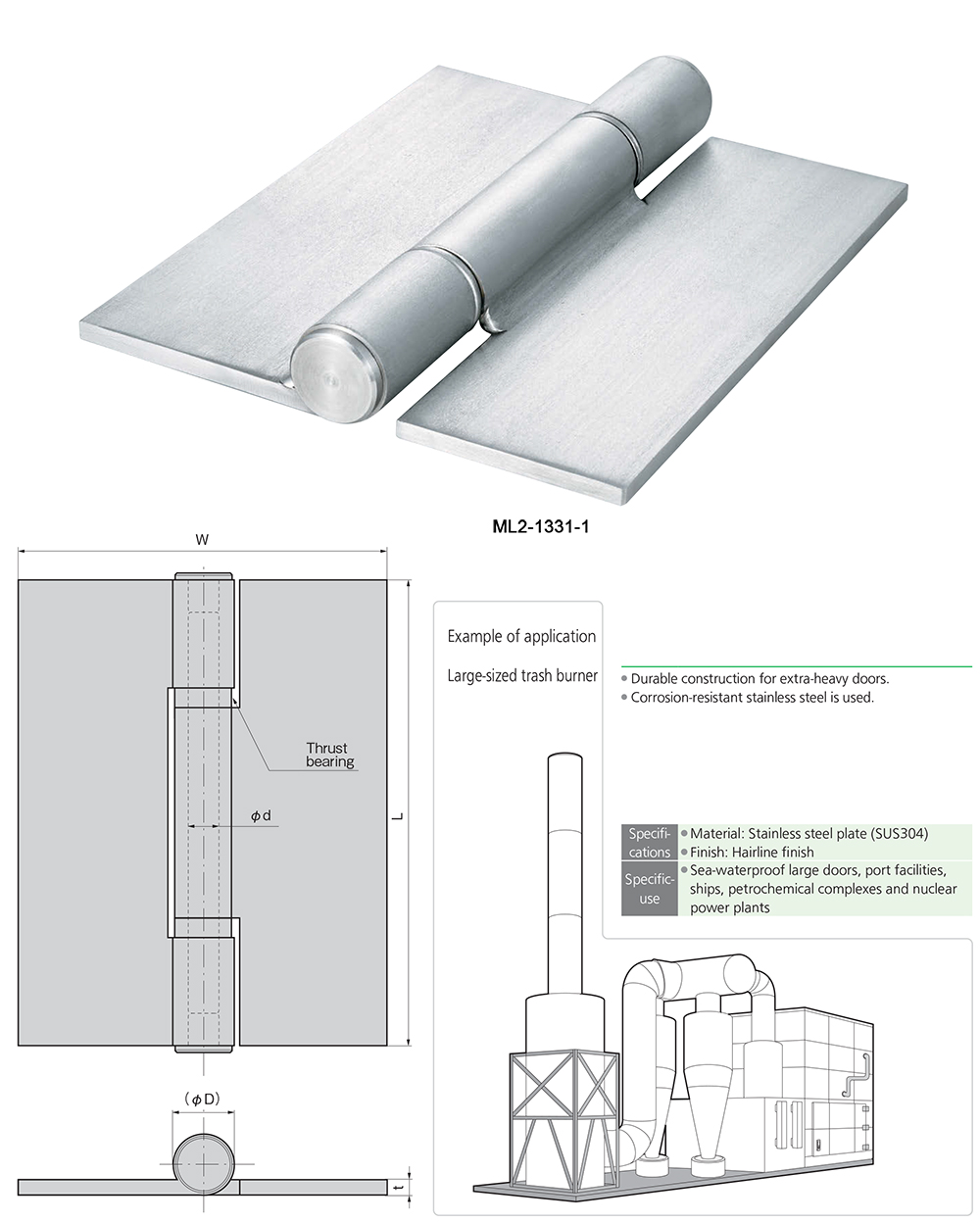

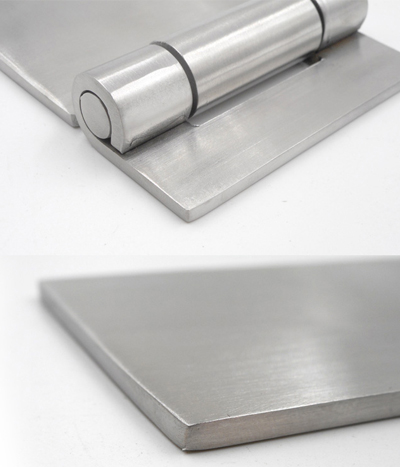

Certainly, the material used to manufacture the hinge is pivotal. For instance, steel hinges are common in industrial settings due to their strength and durability.

However, the material alone can’t be an indicator of a hinge’s ability to bear weight. The design, engineering, and quality of the manufacture also play crucial roles in the overall performance of the hinge. So, while steel might be a superior material, the end performance also hinges (pun intended) on other factors.

Are there specific hinge designs suited for heavy doors?

There is a myriad of hinge designs available for different applications. In the context of heavy industrial doors, some designs are indeed better suited than others.

For example, continuous hinges, also known as piano hinges, run the entire length of the door, distributing the door weight across a larger area. This results in lower stress on individual hinge points, making these designs highly efficient for heavy doors.

How do hinge dimensions impact weight bearing?

Just as the number and placement of hinges matter, so do the dimensions. Larger hinges typically bear weight better because they have a larger pivot point and more material to distribute the load.

But, it’s not only about size. The thickness and length of the hinge also play into its weight-bearing abilities. A thicker hinge can generally hold more weight, while a longer hinge spreads the load more evenly across the door, thus reducing stress.

Does maintenance play a role in hinge performance?

Hinges are mechanical devices that can wear out over time, especially under heavy loads. Regular maintenance and lubrication can drastically extend the life of hinges and keep doors functioning smoothly.

Neg

lected hinges can result in increased friction, wear and tear, and ultimately failure, all of which could cause a considerable interruption to operations in an industrial setting. Hence, regular maintenance isn’t just a recommendation; it’s a necessity.

What is the role of a door’s design and material in hinge weight bearing?

The door’s design and material can significantly affect how the weight is distributed to the hinges. For instance, a solid metal door will distribute weight differently than a hollow metal door, even if the overall weight is the same.

Moreover, a door’s design—whether it’s a single panel or multiple panels—can influence the weight distribution. Hence, the door’s construction and material must be considered when selecting and positioning the hinges.

Conclusion

In the grand scheme of things, it’s not about which individual hinge on a door holds the most weight. Instead, it’s the harmony between all the hinges, their design, placement, number, maintenance, and the door’s own material and design that determines the weight-bearing capacity. So, the next time you look at a hefty industrial door, you’ll appreciate the careful consideration and complex interplay of factors that keep it swinging smoothly and effortlessly.

You might also be interested: