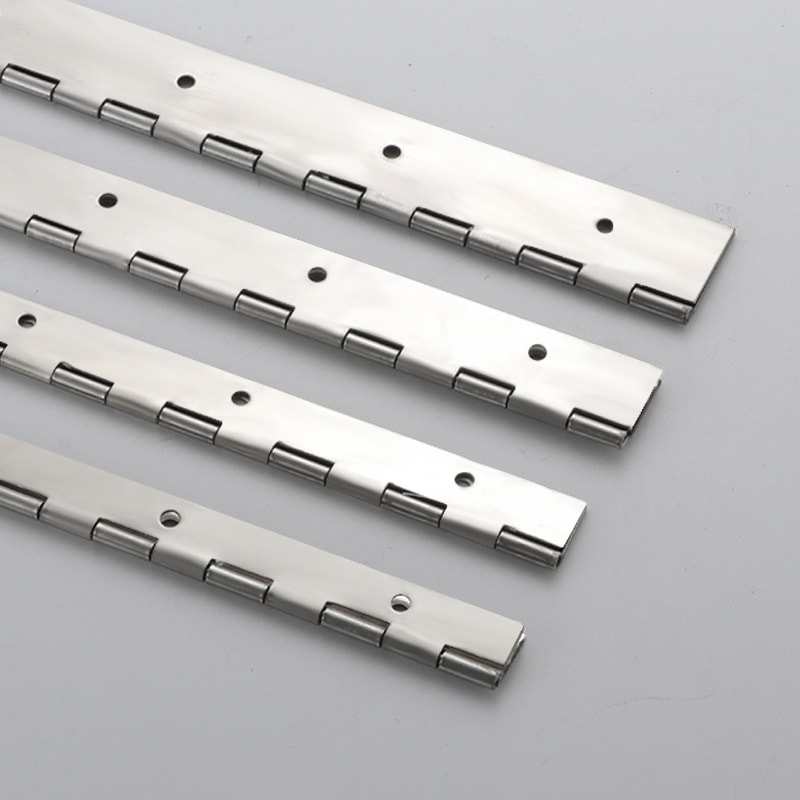

When embarking on a project that requires the precise and reliable movement of doors or panels, selecting the right piano hinge is crucial. These long, continuous hinges are not only pivotal for the seamless operation of the mechanism but also play a significant role in its longevity and durability.

Choosing the appropriate piano hinge can be the difference between a project’s success and failure. It is essential to consider various aspects such as length, width, thickness, material, and whether a perforated design is required. This selection will impact the hinge’s performance, durability, and compatibility with your project.

Selecting the right piano hinge is more than just picking a component; it’s about ensuring the functionality and reliability of your entire project.

The Length of the Piano Hinge

Length is the first critical factor to consider when selecting a piano hinge. The appropriate length of a piano hinge is not just about aesthetics; it plays a pivotal role in the distribution of weight and the ease of movement of the door or panel it supports. A hinge that is too short may not provide enough support, leading to sagging or misalignment over time.

Conversely, a hinge that is too long can be cumbersome and unnecessary. It’s important to measure the full length of the area where the hinge will be installed to ensure a perfect fit. This not only guarantees optimal performance but also enhances the overall appearance of the finished project.

Moreover, in some cases, the length of the hinge can be tailored to specific needs. Custom lengths can be ordered to match unique project requirements, offering a seamless and integrated look. It’s also worth noting that longer hinges distribute the load more evenly across their span, which can be particularly beneficial for heavy or frequently used doors.

Width of Piano Hinge

The width of a piano hinge is another vital aspect to consider, as it directly affects the stability and strength of the hinge’s application. A hinge that is too narrow may not provide sufficient support for the door or panel, especially if it is heavy or subject to frequent use.

On the other hand, a hinge that is too wide can be visually intrusive and may require more material, thus increasing costs. The ideal width should be determined based on the weight of the door or panel and the expected level of usage.

It is also essential to consider the clearance and space available for the hinge. In some instances, the space may be limited, dictating a narrower hinge. Ensuring the hinge width matches the application’s requirements not only supports optimal functionality but also contributes to the longevity of both the hinge and the door or panel it is attached to.

Thickness of the Piano Hinge

The thickness of the piano hinge is crucial for its durability and operational performance. Thicker hinges are generally more robust and can support heavier doors or panels, making them an excellent choice for high-use or industrial applications. However, thicker hinges also require more space and can be more challenging to install. It’s essential to balance the need for strength with the limitations of the project space and the aesthetic considerations.

Furthermore, the thickness of the hinge can affect the ease of movement and the alignment of the door or panel. A hinge that is too thick for the application may cause stiffness in movement or difficulty in achieving a flush fit, while a hinge that is too thin might not provide adequate support, leading to sagging or misalignment over time.

The Material of the Piano Hinge

The material from which a piano hinge is made is a critical factor in its performance, durability, and suitability for specific environments. Common materials include steel, stainless steel, brass, and aluminum, each offering distinct advantages and disadvantages. Steel hinges are strong and cost-effective but may be prone to corrosion if not properly treated.

Stainless steel hinges offer excellent corrosion resistance, making them ideal for outdoor or marine environments. Brass hinges are sought after for their aesthetic appeal, especially in decorative applications, but they may not be as strong as steel or stainless steel. Aluminum hinges are lightweight and resistant to corrosion, making them suitable for applications where weight is a concern.

Choosing the right material depends on the specific requirements of the project, including environmental exposure, aesthetic considerations, and load-bearing needs. It is essential to select a material that not only meets the functional requirements but also complements the overall design of the project.

Does It Need to Be Perforated?

The decision to choose a perforated or non-perforated piano hinge is largely dependent on the specific needs of the project and the method of attachment preferred. Perforated hinges come with pre-drilled holes, facilitating easier and quicker installation, as they can be directly screwed into the mounting surface.

This can be particularly useful in projects where time or ease of installation is a priority. However, the presence of holes may slightly reduce the hinge’s strength compared to a non-perforated hinge, where the attachment method can be customized, such as welding, for a stronger bond.

It’s also worth considering the aesthetic impact of the choice. In some cases, the visibility of screws in a perforated hinge may not be desirable, whereas a non-perforated hinge offers a cleaner, more seamless appearance. Ultimately, whether to choose a perforated hinge should be based on the installation method that best suits the project’s requirements, considering both practicality and aesthetics.

Conclusion

Selecting the right piano hinge is essential for the success of any project involving doors or panels. By carefully considering the hinge’s length, width, thickness, material, and whether it needs to be perforated, one can ensure optimal performance, durability, and aesthetic appeal. Understanding these aspects allows for an informed decision that aligns with the project’s specific needs, ensuring that the final installation is both functional and visually pleasing.

You may be interested:

- 5 Features You Should Know About Heavy Duty Stainless Steel Piano Hinges

- What Are the Types of Piano Hinges?

- What are Flush Hinges and How Do They Work?

- What is a Knuckle Hinge?