Hinges that can be cut to length provide flexibility for various applications, ensuring a precise fit for doors, panels, and enclosures. Some hinge types are specifically designed for trimming to achieve custom sizes.

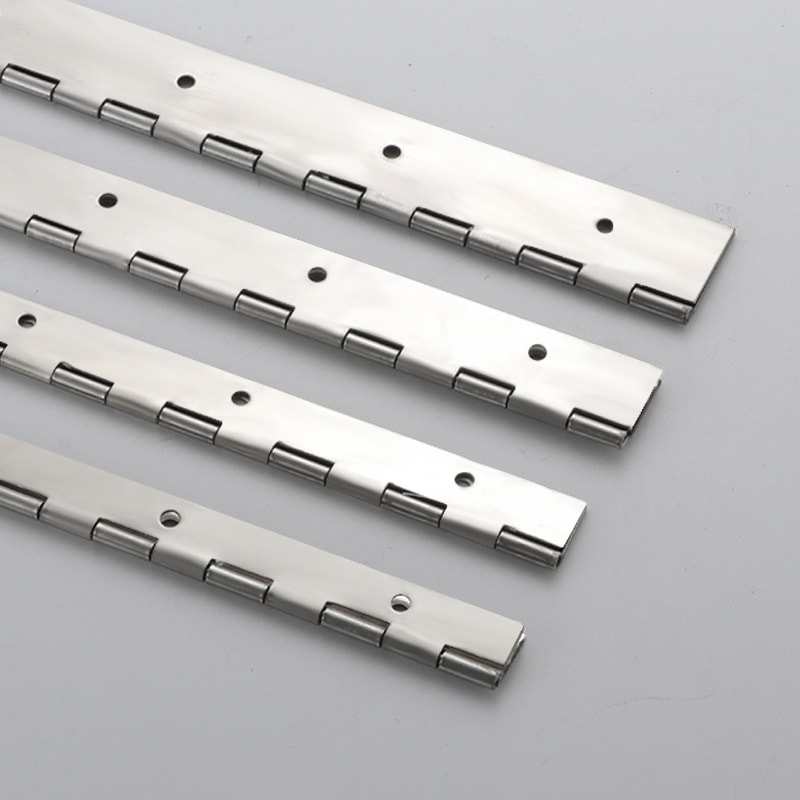

A continuous hinge, also known as a piano hinge, is the most common type that can be cut to length. These hinges run the full length of doors or panels and can be trimmed using appropriate tools. Other hinges, such as offset hinges and some flexible hinges, can also be cut for custom applications.

To better understand which hinges can be cut to length and how to modify them properly, let’s explore the options available and the best practices for cutting hinges.

What is a Continuous Hinge, and Can It Be Cut to Length?

Continuous hinges, commonly referred to as piano hinges, are long, straight hinges designed to distribute weight evenly along the length of a door or panel. These hinges are widely used in industrial applications, providing strength and durability.

Yes, a continuous hinge can be cut to length to fit custom applications. Typically made from stainless steel, brass, or aluminum, these hinges provide a strong pivot for doors, toolboxes, and enclosures. Cutting requires a hacksaw or metal-cutting tool, followed by smoothing the edges for safe installation.

Cutting a Continuous Hinge: Key Considerations

- Material Selection: Stainless steel piano hinges offer corrosion resistance, while aluminum hinges provide lightweight strength.

- Cutting Techniques: Use a fine-tooth hacksaw, angle grinder, or metal snips for clean cuts.

- Industrial Applications: Common in cold storage room hinges and trailer door hinges, continuous hinges provide strong support for heavy doors.

- Weight Capacity: These hinges can support substantial loads when properly installed, making them suitable for heavy-duty industrial enclosures.

What Other Hinges Can Be Cut to Length?

Besides continuous hinges, some offset hinges and flexible hinges can be trimmed for specific applications. These hinge types are useful in industrial equipment, machinery, and enclosure manufacturing.

Offset hinges and flex hinges can be cut to length to accommodate unique door clearances and custom installations. While continuous hinges are typically metal, flexible hinges may be made from plastic or composite materials and can be easily trimmed for specialized use.

Hinges That Allow Custom Length Adjustments

| Hinge Type | Cuttable to Length | Common Applications |

|---|---|---|

| Continuous Hinge | Yes | Industrial doors, enclosures |

| Offset Hinge | Yes | Cabinets, machinery doors |

| Flex Hinge | Yes | Custom motion applications |

| Butt Hinges | No | Residential doors |

- Offset Hinges: Ideal for clearance adjustments in industrial hinge production base applications.

- Flexible Hinges: Used in climatic test chamber hinges for precision door movements.

- Cutting Process: Requires hacksaws, metal shears, or rotary cutting tools for an accurate cut.

Differences Between Continuous Hinges and Regular Hinges

A continuous hinge extends along the entire length of a door, ensuring even weight distribution, whereas a regular hinge consists of multiple separate hinge sections mounted at specific intervals.

Continuous hinges provide better strength and durability compared to regular hinges. Unlike regular hinges, continuous hinges can be cut to size, making them more adaptable for industrial applications.

Comparing Continuous Hinges and Regular Hinges

| Feature | Continuous Hinges | Regular Hinges |

|---|---|---|

| Length | Full-length | Fixed sizes |

| Weight Distribution | Even | Concentrated on hinge points |

| Cut to Length | Yes | No |

| Common Use Cases | Industrial enclosures, toolboxes | Residential doors, cabinets |

- Installation Requirements: Continuous hinges require a full-length mounting surface, whereas regular hinges only need spaced mounting points.

- Durability and Load Capacity: Continuous hinges are ideal for marine hinges and weld on hinges, offering increased strength in industrial settings.

Considerations When Cutting a Hinge to Length

To ensure functionality, cutting a hinge requires proper tools, precision, and finishing techniques. Consider hinge material, cutting method, and edge finishing for smooth operation.

When cutting a hinge to length, use a hacksaw or metal-cutting tool for a clean edge. Avoid cutting near pre-drilled holes to maintain hinge strength. File sharp edges after cutting for safe handling.

Best Practices for Cutting Hinges

- Measure the required length and mark the cut precisely.

- Secure the hinge in a vice before cutting to prevent movement.

- Use the right tool—hacksaws for metal, metal snips for thin materials.

- Smooth edges using a metal file to prevent sharp burrs.

- Test fit the hinge before final installation to ensure proper alignment.

Avoiding Common Mistakes

| Mistake | Consequence |

|---|---|

| Cutting near mounting holes | Weakens hinge structure |

| Using improper tools | Uneven cuts, damage to hinge |

| Not filing edges | Risk of injury and improper door movement |

Conclusion

Certain hinges, especially continuous (piano) hinges, can be cut to length for custom industrial and heavy-duty applications. Cutting requires the right tools and careful measurement to maintain hinge integrity. Whether for marine hinges, cold storage room hinges, or heavy-duty enclosures, choosing the correct hinge type ensures durability, strength, and functionality.