Have you ever paused to consider the complexities of hinge design and its vital role in industrial manufacturing? They may seem like simple, inconspicuous pieces of hardware, but their design and classification are crucial to the functioning of various industrial machines and equipment.

At the heart of many pieces of industrial machinery, hinges facilitate motion between connected parts. They come in various types, each designed for a specific application, with different classifications based on their function, shape, and material.

While we may not always recognize it, these small, often overlooked components play a pivotal role in ensuring the smooth operation of various industrial machinery, contributing to the overall efficiency and productivity of manufacturing processes.

What Factors Determine Hinge Classification?

In the world of industrial manufacturing, hinge classification is primarily determined by three main factors: function, shape, and material. These factors, in combination, help engineers and manufacturers choose the right hinge for each specific application.

Firstly, function pertains to how the hinge operates. The type of motion it needs to facilitate and the load it has to bear play crucial roles in determining the function of a hinge. On the other hand, the shape and material of the hinge are typically chosen based on the specifics of the industrial machinery where it will be used.

What is the Role of Hinge Function in Classification?

The function of a hinge is a crucial determinant of its classification. Some hinges are designed to facilitate simple motion, such as opening and closing, while others are engineered for complex motions or to bear heavy loads.

For instance, a continuous hinge, often found in industrial machinery, provides support across the entire length of the door or lid, distributing the weight evenly. On the other hand, pivot hinges, which rotate around a single point, are often used in applications requiring rotational movements, like rotating platforms or conveyors.

How Does Shape Influence Hinge Classification?

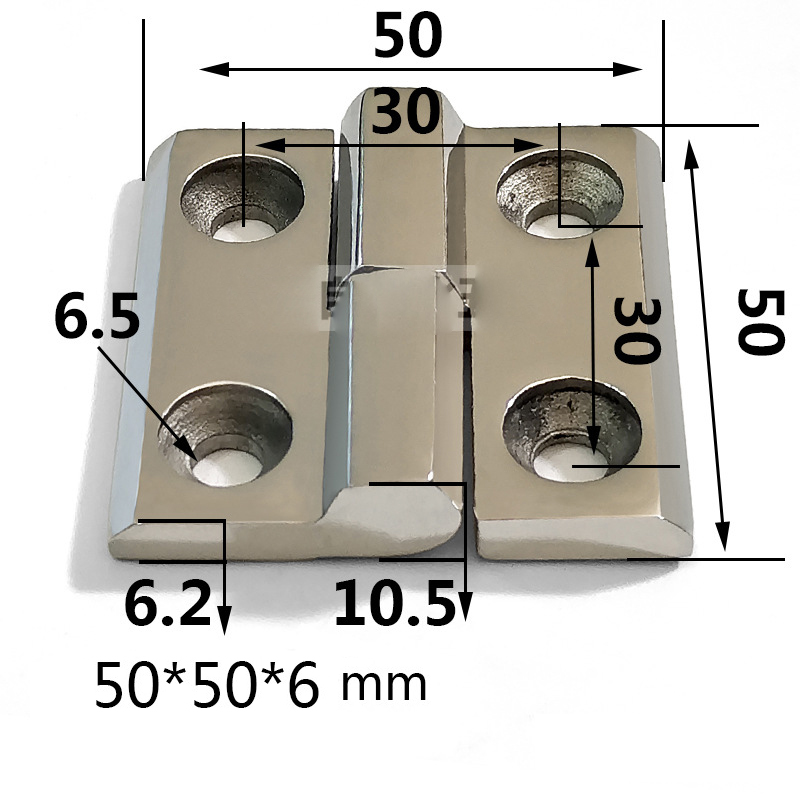

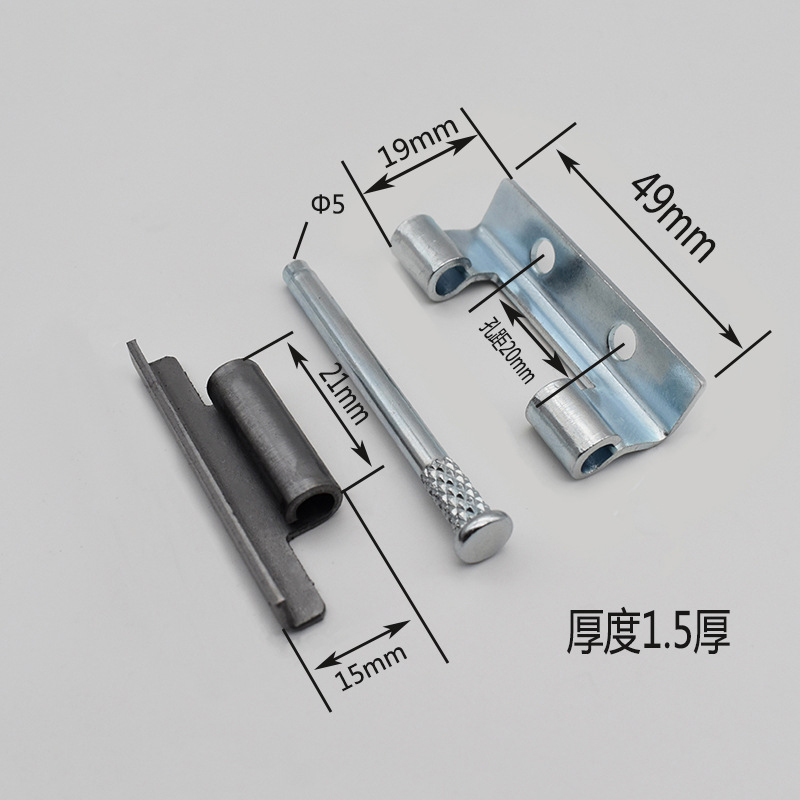

When it comes to the shape of hinges, it’s all about fitting the specific requirements of the machinery. Shapes range from square and rectangular, to round, and even custom shapes to suit particular industrial applications.

Consider the piano hinge, for example. This long, narrow hinge, named for its use in piano lids, is often used in industrial applications where a long, continuous hinge line is required. Conversely, the butterfly hinge, named for its distinctive shape, is typically used in instances where the visual appeal of the hinge is as important as its function.

Why is Material Important in Hinge Classification?

The material from which a hinge is made significantly influences its classification, as it directly impacts the hinge’s strength, durability, and resistance to environmental conditions. This factor is of immense importance in the industrial sector where hinges often need to withstand harsh conditions.

Stainless steel hinges, for example, are renowned for their corrosion resistance and strength, making them ideal for applications where the hinge will be exposed to moisture or harsh chemicals. On the other hand, brass hinges are known for their malleability and aesthetics, often used in applications where both the function and appearance of the hinge are of significance.

Can Hinges Be Sub-classified?

Within the aforementioned categories, hinges can be sub-classified further. This allows for an even more precise specification to ensure the hinge meets the exact needs of the application.

For instance, under the function category, you might find load-bearing hinges further classified by the specific weight they can support. Similarly, shape can be sub-classified by the precise measurements and angles, and material can be further divided based on the specific alloy or finish used.

How is Hinge Classification Applied in Industry?

Understanding hinge classification allows professionals in the industrial sector to make informed decisions when it comes to choosing the appropriate hinge for their machinery. This, in turn, can lead to increased efficiency, reduced maintenance costs, and improved longevity of the machinery.

For example, knowing that a piano hinge can distribute weight evenly along its length might make it the hinge of choice for a machine door that requires frequent opening and closing. Similarly, understanding that stainless steel hinges can withstand harsh environments can help when choosing hinges for machinery used in such conditions.

Conclusion

In summary, the classification of hinges in industrial manufacturing revolves around function, shape, and material, with further potential for sub-classification within each of these categories. Recognizing the importance of these classifications helps industry professionals select the optimal hinge for their machinery, contributing to efficiency, cost-effectiveness, and overall machine lifespan. As inconspicuous as they may seem, hinges indeed play a crucial role in the world of industrial manufacturing.

You might also be interested: