A continuous hinge provides seamless and durable support for doors and panels in various industrial and commercial applications.

A continuous hinge, often called a piano hinge, is best used for heavy or frequently operated doors, providing even weight distribution and long-lasting support. It enhances durability, stability, and aesthetics in applications like industrial equipment, commercial doors, and storage containers.

Let’s explore the best uses for continuous hinges, their advantages, and why they are a preferred choice in various industries.

What is a Continuous Hinge?

A continuous hinge is a long, narrow hinge running the entire length of a door or panel, distributing stress evenly.

Continuous hinges minimize wear by distributing stress evenly across their length, ideal for high-traffic or heavy-duty applications.

Made from materials like aluminum, steel, or stainless steel, continuous hinges are designed to withstand repetitive motion and heavy use. They are often used in industrial and commercial applications where stability and durability are essential. For example, aluminum geared continuous hinges are preferred for their lightweight yet sturdy structure, making them ideal for applications such as industrial doors and soft close hinges.

Key Benefits of Continuous Hinges

Continuous hinges offer unmatched durability, smooth operation, and aesthetic advantages.

Continuous hinges ensure even weight distribution, reduce sagging, and extend the life of doors, making them perfect for high-use environments.

Benefits at a Glance:

- Durability: Their design prevents door misalignment or sagging over time.

- Noise Reduction: Operates quietly, ideal for offices or healthcare facilities.

- Aesthetic Appeal: Concealed fasteners create a clean, professional finish.

- Versatility: Suitable for indoor and outdoor use, including marine applications requiring corrosion resistance.

Applications such as marine hinges take advantage of their ability to withstand environmental factors like moisture and salt, ensuring longevity in challenging conditions.

Common Applications of Continuous Hinges

From industrial equipment to commercial doors, continuous hinges serve in diverse settings.

Continuous hinges are used in heavy doors, storage lockers, industrial panels, and equipment access points for stability and longevity.

Key Uses:

- Industrial Applications: Used in heavy machinery panels for durability and precise alignment.

- Commercial Buildings: Installed on doors in schools, hospitals, and retail stores for high-traffic use.

- Outdoor Environments: Durable enough to endure harsh weather conditions, making them ideal for applications like trailer door hinges or marine environments.

Types of Continuous Hinges

Continuous hinges come in various types to meet specific needs, such as geared, heavy-duty, or standard piano hinges.

Types include geared continuous hinges, heavy-duty piano hinges, and concealed hinges, each tailored to specific applications and weight requirements.

| Type | Use Case | Material Options |

|---|---|---|

| Aluminum Geared Hinges | Heavy-duty industrial doors, soft-close designs | Aluminum, Stainless Steel |

| Heavy-Duty Piano Hinges | Sheds, industrial equipment access panels | Stainless Steel, Brass |

| Concealed Hinges | Hidden doors, aesthetic installations | Steel, Aluminum |

For specific applications, piano hinges provide the strength and durability required for large doors or panels while maintaining a sleek appearance.

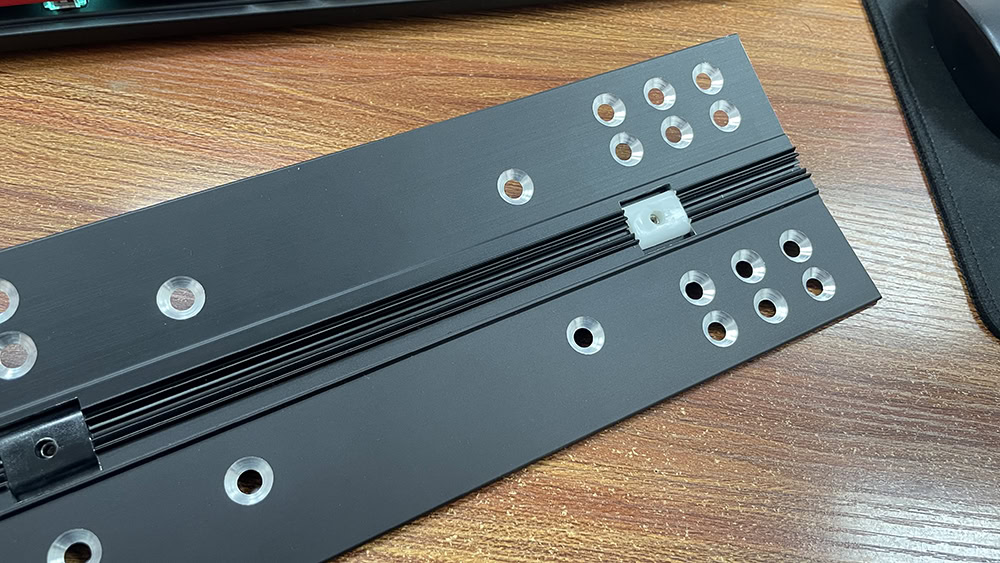

Installation of Continuous Hinges

Installing continuous hinges requires precision for proper weight distribution and smooth operation.

To install a continuous hinge, align it along the door and frame, mark screw holes, drill, and fasten securely.

Installation Steps:

- Align the hinge with the door and frame edges for a perfect fit.

- Use a drill to create pilot holes at marked points.

- Secure the hinge with screws, ensuring even pressure across its length.

- Test the door’s functionality to confirm smooth operation.

Some hinges, like cold storage room hinges, require additional insulation layers during installation for thermal efficiency.

When to Use a Continuous Hinge Over Other Hinges

Continuous hinges are ideal when durability and even load-bearing are priorities over traditional hinge styles.

Opt for continuous hinges for heavy doors, high-traffic areas, or applications requiring extended durability and smooth functionality.

Compared to alternatives:

- Butt Hinges: Work well for lightweight doors but lack even weight distribution.

- Detachable Hinges: Useful for quick door removal but less stable for heavy-duty usage.

- Continuous Hinges: Outperform in strength, stability, and seamless appearance, ideal for heavy industrial and commercial use.

Conclusion

Continuous hinges excel in durability, versatility, and load distribution, making them a superior choice for industrial, commercial, and heavy-duty applications. Their wide-ranging benefits and reliability make them indispensable in demanding environments.