In a world of evolving technology and machinery, the importance of small components often gets overlooked. While most might not have heard of it, the stepped hinge plays a crucial role in many industrial applications. It’s the unsung hero ensuring flexibility and movement in certain equipment setups.

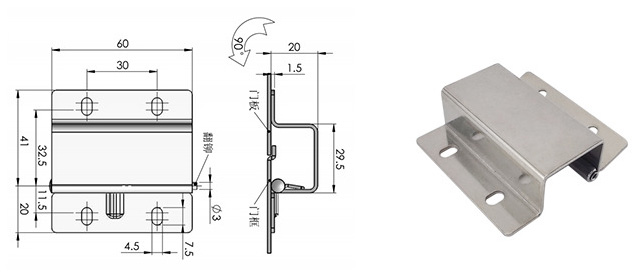

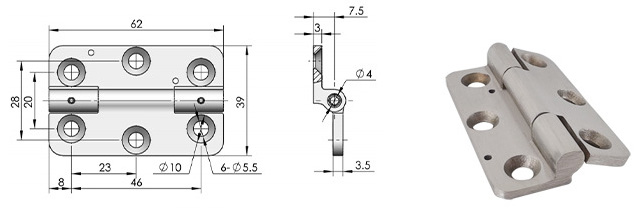

A stepped hinge, distinct from regular hinges, is a specialized hinge designed to accommodate uneven or stepped surfaces. This hinge is crafted to align two non-levelled surfaces, providing smooth movement and solid connection, especially in industrial settings.

Understanding this seemingly modest component can lead to optimal equipment performance. Let’s venture into the particulars of the stepped hinge.

Why Are Stepped Hinges Different from Regular Hinges?

Standard hinges, though versatile, don’t always cater to unique industrial demands. Here lies the brilliance of the stepped hinge. It’s specifically engineered for joining surfaces that are not on the same level. The unique design allows for a snug fit, ensuring stability and seamless movement.

Its distinctive stepped structure enables the hinge to latch onto uneven or tiered surfaces. This not only ensures a secure fit but also promises a smooth operational flow, which is crucial for many industrial applications.

In Which Industries Are Stepped Hinges Predominantly Used?

Stepped hinges aren’t just a random invention. Their design responds to a real need in certain industries. Predominantly, sectors that employ machinery or equipment requiring adaptable components, like the stepped hinge, benefit the most.

Typically, you’ll find these hinges in large-scale manufacturing units, automotive industries, or any sector where equipment requires flexibility in joining uneven components. Their ability to offer both stability and movement makes them indispensable in these settings.

How Do Stepped Hinges Enhance Equipment Efficiency?

Equipment efficiency often hinges (pun intended) on the small components. Stepped hinges, by their very design, ensure that two uneven surfaces connect seamlessly. This eliminates any wobbling or instability that might arise from using a regular hinge in such scenarios.

When surfaces are securely joined without any play or unnecessary movement, equipment operates more efficiently. This can lead to fewer maintenance issues, longer machinery life, and enhanced operational output.

What Materials Are Used to Manufacture Stepped Hinges?

While the design is paramount, the material used in manufacturing a stepped hinge is equally vital. Durability, resistance to wear, and the ability to bear weight all depend on the chosen material.

Commonly, materials like stainless steel, brass, or even certain alloys are employed. The choice often depends on the hinge’s intended use. For instance, stainless steel might be preferred for its corrosion resistance in environments where the hinge might be exposed to moisture or chemicals.

Are There Customizable Options for Stepped Hinges?

Given the myriad of industrial applications, one size doesn’t fit all. Recognizing this, many manufacturers offer customization options for stepped hinges. Whether it’s the size, the angle of the step, or the material used, customization can cater to specific equipment needs.

Such tailored solutions ensure that the hinge perfectly fits its intended application, further enhancing the equipment’s performance and lifespan.

How Does One Maintain and Care for Stepped Hinges?

Like all mechanical components, stepped hinges require periodic maintenance. Proper care can extend their lifespan and ensure consistent performance. Regularly checking for wear and tear, applying suitable lubricants, and ensuring they’re free from dust and debris are some of the primary maintenance activities.

By investing a little time in their upkeep, one can avoid more significant issues down the line, ensuring the equipment’s uninterrupted functionality.

Are Stepped Hinges Easily Replaceable?

Yes, the beauty of stepped hinges lies not only in their functionality but also in their replaceability. If a hinge shows signs of wear or isn’t functioning optimally, it can be swapped out without much hassle. However, it’s essential to replace it with a hinge of the same specifications or one that’s compatible with the equipment.

Choosing the right replacement ensures that the equipment continues to operate efficiently without any hiccups or malfunctions.

Conclusion

At the heart of efficient machinery often lies components like the stepped hinge. Though they might seem insignificant, their role in ensuring smooth operation is undeniable. By understanding their function, design, and maintenance, industries can enhance the longevity and efficiency of their equipment.

For those exploring hinge solutions, we’re here to serve. As a dedicated industrial hinge manufacturer, our prowess lies in providing top-tier quality at competitive prices. We specialize in crafting customized industrial hinges to meet unique equipment installation demands. Do reach out for a bespoke quote.

You might also be interested: