Weldable steel hinges are essential components in the realm of industrial equipment. These hinges are specifically designed for applications in electrical cabinets, network enclosures, and other industrial machinery. Their reliable performance and stability make them the preferred choice for securing doors in these settings.

What are the characteristics of weldable steel hinges?

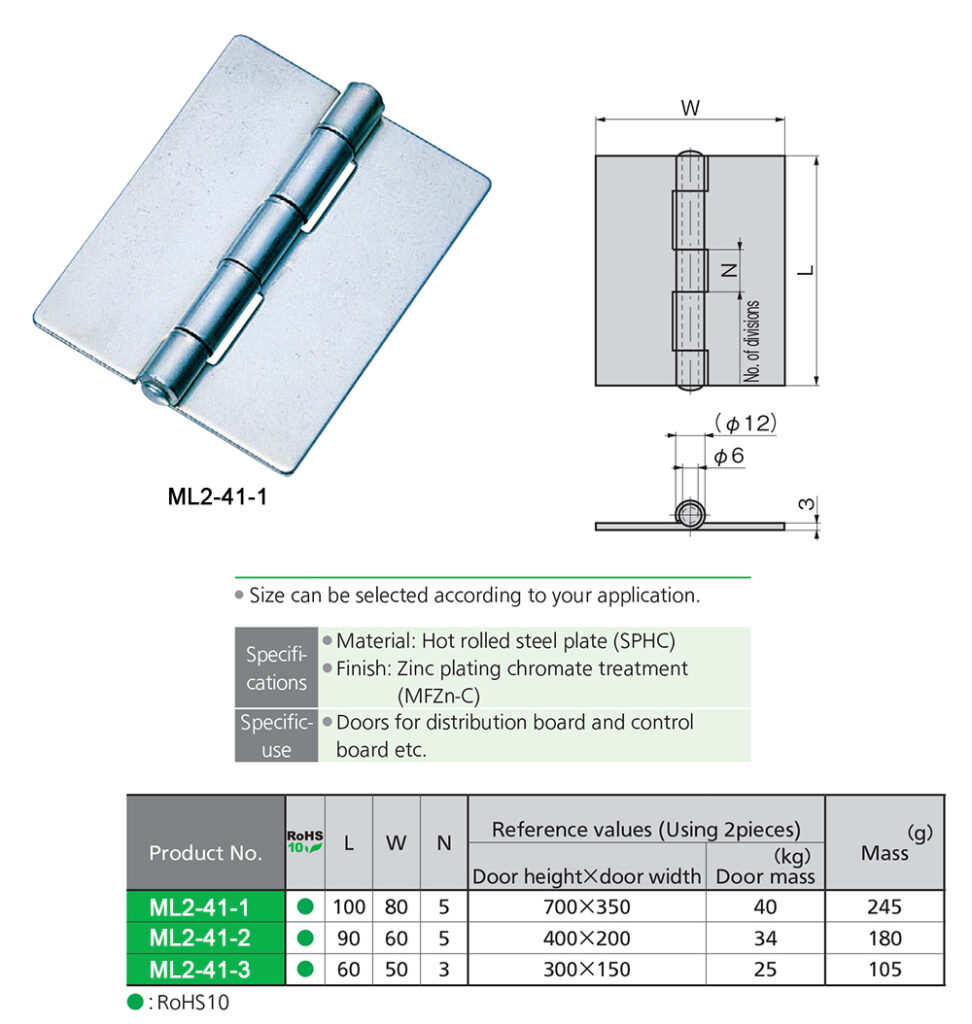

Weldable steel hinges exhibit several key characteristics that set them apart in industrial environments. Firstly, they are constructed using high-quality steel materials, ensuring exceptional durability and strength. This enables them to withstand prolonged usage and heavy loads without compromising their functionality. Secondly, their design facilitates easy welding and installation, allowing for a secure and seamless connection between the hinge and the door. Additionally, it can be customized to meet various specifications, including size, shape, and material, ensuring compatibility with a wide range of industrial equipment.

What material is used for weldable steel hinges?

Weldable steel hinges are crafted from top-grade steel materials, ensuring their longevity and performance. These hinges are typically made from carbon steel or stainless steel, both of which possess excellent strength and corrosion resistance properties. Carbon steel hinges are renowned for their robustness and cost-effectiveness, making them suitable for most industrial applications. On the other hand, stainless steel hinges provide superior resistance to corrosion and are commonly used in environments where moisture or chemicals are present.

How to install weldable steel hinges?

Installing the hinges requires proper technique and attention to detail. Here is a step-by-step guide to assist in the installation process:

1. Prepare the materials: Gather the necessary tools, including a welder, welding electrodes, safety equipment, and a measuring tape.

2. Mark the placement: Determine the precise location where the hinge will be welded onto the door and frame, ensuring proper alignment.

3. Prepare the surfaces: Clean the welding areas on the hinge, door, and frame to remove any debris or contaminants that may interfere with the weld.

4. Weld the hinge: Use the appropriate welding technique and electrode to secure the hinge to the door and frame. Ensure a strong and stable weld.

5. Test the functionality: Open and close the door to ensure smooth movement and proper alignment of the hinge. Make any necessary adjustments if required.

What are the uses of weldable steel hinges?

Weld on steel hinges finds widespread applications in industrial settings. They are primarily used for securing doors in electrical cabinets, network enclosures, control panels, and other equipment requiring reliable access and protection. These hinges provide stability and security, ensuring that doors remain securely closed while allowing easy access when needed. Their versatility also makes them suitable for use in various sectors. Including manufacturing, telecommunications, and power distribution.

How to customize weldable steel hinges?

As a professional manufacturer of weldable steel hinges, we understand the importance of customization to meet specific requirements. We offer a range of customization options, allowing customers to tailor hinges according to their unique needs. This includes customization of sizes, shapes, and designs, ensuring a perfect fit for different equipment and door configurations. Moreover, we provide various material options to accommodate diverse environmental conditions, such as high humidity or extreme temperatures.

Also, we can always make industrial hinges with holes for installation according to customer requirements. All that is required is to drill holes in the hinge block.

Conclusion

Weldable steel hinges are essential components in industrial equipment, providing stability, security, and ease of use. Their durability, strength, and customization options make them a reliable choice for securing doors in electrical cabinets, network enclosures, and similar applications. With proper installation and attention to detail, the hinges offer long-lasting performance and ensure the smooth operation of industrial equipment.