The hinge is a hardware accessory that is often overlooked in our work and life. This is mainly because it is not too directly related to our life. But in the industrial field or in the construction or furniture field you can often come into contact with these products. In this article, I will introduce you to the top 10 types of industrial hinges.

It is important to note that I will distinguish between hinges used in the industrial equipment sector and those used in the construction and furniture sectors. To some extent, there is a difference between the hinges used in these two fields. I will focus on the types of hinges used in industrial equipment.

Types of industrial hinges: Butt Hinges

This types of industrial hinges is a very common type of hinge, which consists of two symmetrical hinge leaves and a hinge pin, and is relatively modest. It is also the most widely used type of hinge in the industrial sector.

Usually, this type of hinge is widely used, and most of the industrial box equipment in the market can use this type of hinge, which is convenient and affordable. These hinges are not very heavy-duty, but since most of them are made of metal, they can meet the requirements of most industrial equipment doors.

Another characteristic of butt hinges is that they are mainly flat-mounted. The two hinge blocks are symmetrical and are also kept on the same horizontal plane. When you install the hinges, there is no need to distinguish between the left or right side of the hinge, as it is universal for left and right.

Types of industrial hinges:Concealed Hinges

Concealed hinges are a slightly special type of hinge that is related to removable hinges, mainly because they do not have enough space to install screws or weld on when they are installed. This is when engineers tend to design concealed hinges to be removable. This allows the door to be assembled after the two hinge leaves have been installed on the door and the door frame respectively.

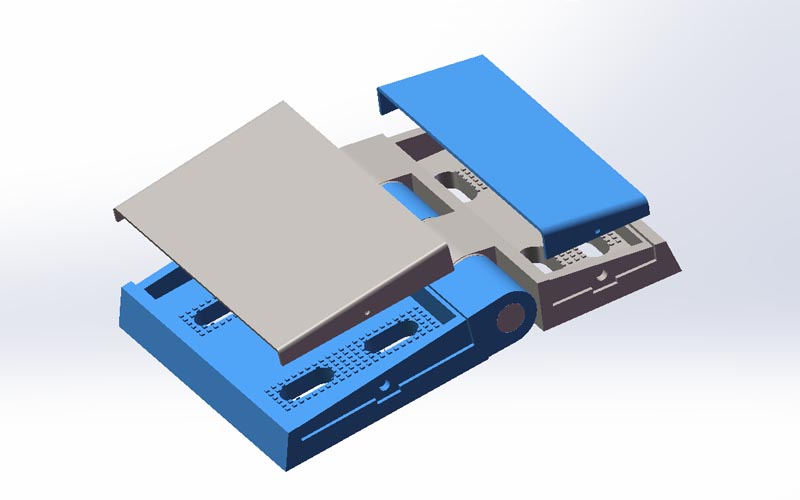

The most important feature of hidden hinges is their invisibility. This means that when the hinge is installed, the hinge is not visible from the outside of the unit, it is completely hidden inside the door. This installation method can improve the overall simplicity and beauty of the equipment. This types of industrial hinges is mainly used on some electrical boxes, electrical cabinets, control cabinets, and other equipment.

The structure of hidden hinges is generally simply because these hinges are installed in a relatively small space, and too complicated a structure will affect its installation and subsequent maintenance. Moreover, by installing the hinge inside the door, a certain amount of installation space needs to be reserved for it. This will take up the space inside the device, and if the structure is too complex it will need to take up more space.

Types of industrial hinges:Heavy-duty Hinges

Heavy-duty hinges are the type of hinges that we focus on in our factory. These hinges are called heavy-duty hinges because they have a high load-bearing capacity and are mainly used for doors that are relatively heavy. For example, the doors of some large facilities are often very heavy, especially when some functional accessories are installed on the doors.

In order to be able to withstand the weight of such heavy doors, we have developed a series of heavy-duty hinges. Most of the heavy-duty hinges manufactured by IHINGES are made of stainless steel and are produced through a die-casting process.

The choice of material is the one that most directly affects the hinge’s load-bearing capacity, so when we order heavy-duty hinges for our customers, the first thing we determine is the material. For safety reasons, we sometimes recommend that our customers use a better material even though other materials may be used to meet the requirements. This is because it is possible that the customer’s equipment is very expensive and will not be able to withstand any accidents.

Types of industrial hinges: Detachable Hinges

Detachable Hinges, as the name implies, are hinges that can be removed. As we know, the base of a hinge is composed of two hinge leaves and a hinge pin. It doesn’t matter if at least the two hinge leaves are the same, or if they are symmetrical. This is the simplest hinge composition.

Then if the hinge is removable, it means that the two hinge leaves are separable from each other, and even between the hinge leaves and the hinge pin. There is a market demand for this hinge design because sometimes our equipment doors need to be completely disassembled. It would be troublesome to remove the screws every time the door is disassembled.

So the engineers thought of thinking of a way to the hinge and designed the hinge pins and hinge blocks to be a separable structure. This way when we need to disassemble the door as a whole, we only need to lift the door up, without removing the screws, which is very convenient.

Cold Storage Room Hinges

Cold Storage Room Hinges are a class of hinges specifically designed for use in freezer rooms. These hinges are often used in humid and cold environments. Therefore, the requirements for hinges are relatively high. Freezer hinges are often made of zinc alloy or stainless steel. This also depends on the environment and load-bearing requirements.

If the freezer hinge is made of zinc alloy, the surface needs a very good surface treatment. This is to protect it from corrosion during long periods of moisture and low temperatures. These hinges often have a chrome-plated finish, and the result is very beautiful. Freezer hinges made of stainless steel often only need to be polished beautifully on the surface, which itself has anti-corrosion properties.

Spring Hinges

The most important feature of spring hinges is the addition of a spring mechanism to the hinge. So why do you need to install springs? It is mainly due to practical needs. In our daily life, for example, we often see doors that close automatically after being pushed open, thanks to springs.

Similarly in the industrial sector, spring hinges are also used, except that they may not be able to support doors that are too heavy as heavy hinges. The initial state of a spring hinge is folded up. When it is installed on a door, the hinge will open to a certain angle when we push the door open, and it will automatically fold back to its initial state when we release the door.

One detail to pay attention to when installing spring hinges is the need to install a cushioning device on the door, because the spring rebound is an accelerated process, and if a cushioning device is not installed, there is a possibility of making a loud noise at the moment the door closes. This experience is very poor, think about it is very uncomfortable.

Offset Hinges

Offset Hinges are mainly hinges where the two hinge leaves are not symmetrical. And are different in size, often larger on one side and smaller on the other. Why do hinge engineers design them this way? This is because when the hinge is installed on an equipment door. One side is mounted on the door frame and the other side is mounted on the door panel.

The width of the door frame is often narrow. So the hinge block mounted on the door frame cannot exceed the width of the door frame. But the width of the door panel is wide enough. So the hinge block mounted on the door panel can be designed to be wider, and this is where the offset hinge comes from.

Piano Hinges

Piano hinges are a types of industrial hinges that is much longer than its width. I am not sure why they are called piano hinges. It may be because they are installed on the lid of the piano, so they are called piano hinges. They are also called continuous hinges, probably because they seem to be long and continuous. That is why they are called continuous hinges.

Piano hinges distribute the weight of the door evenly throughout the hinge, giving a very secure psychological feeling. Because you can see that the whole door is covered by the hinge block. If you need to order a piano hinge. You need to consider the length of the hinge, the thickness of the material. The thickness of the hinge pins, whether it is pre-punched for installation or welded for installation.

Rising Butt Hinges

Rising hinges are hinges that raise the height of the door during the opening process. This type of hinge is less used in the industrial field because the load-bearing property of this type of hinge is relatively poor. And the hinge is lifted entirely by two hinge blocks pushing each other to achieve the purpose of lifting. This hinge leaves over time and is easy to wear.

And if the hinge is not well lubricated. The hinge leaves are prone to rattling in the process of rubbing against each other. A problem that is more likely to occur with hinges. On the issue of hinge rattling, here is an article dedicated to How to avoid rattling when hinges rotate.

Special Hinges

Special Hinges are a class of hinges that are used on a variety of special equipment. Or they are hinges that are specifically tailored to the customer’s equipment. These hinges can only be used on one type of equipment because they are custom-made. There is a good chance that they will not work on other equipment.

Special hinges are a category of hinges that IHINGES pursues. And we are committed to providing our customers with industrial hinges that are more specialized. And better suited to their products. In the process of ordering special hinges, the design capability of our engineers is also enhanced. Allowing us to accumulate more experience in hinge production.

If you have hinge customization needs, why not contact us now?