Stainless steel weld-on hinges are vital components designed for heavy-duty and industrial applications, known for their durability and reliability.

Stainless steel weld-on hinges are primarily used in industrial machinery, heavy gates, and marine environments. Their rust resistance, load-bearing capacity, and seamless design make them ideal for demanding conditions.

Explore the extensive uses of stainless steel weld-on hinges across various industries and environments.

What Are Stainless Steel Weld-On Hinges?

Stainless steel weld-on hinges are specialized hardware designed for permanent installation. Unlike traditional hinges that require screws or bolts, weld-on hinges are directly welded to the structure, ensuring long-lasting stability and durability.

These hinges are often constructed from high-grade stainless steel, offering superior resistance to corrosion and wear, making them suitable for both indoor and outdoor applications.

Weld-on hinges, such as trailer door hinges, stand out for their robustness and ability to handle significant weight. Their seamless integration ensures a clean and professional finish for industrial and commercial use.

Advantages of Stainless Steel Weld-On Hinges

Stainless steel weld-on hinges offer exceptional resistance to environmental factors like rust, wear, and extreme temperatures. This makes them a top choice for industries that prioritize long-term reliability.

Durability and low-maintenance requirements are key benefits. Weld-on hinges are cost-effective in the long run, as they minimize the need for frequent replacements and repairs.

Additionally, their ability to withstand heavy loads, such as marine hinges used in coastal environments, highlights their versatility and value.

Applications in Industrial Equipment

Industrial machinery often requires hinges that can endure constant movement and substantial weight. Stainless steel weld-on hinges are commonly used in machine panels, access doors, and covers.

Their robust construction ensures functionality even under continuous stress, reducing downtime in industrial operations.

These hinges provide secure fastening for equipment like climatic test chamber hinges, ensuring precise alignment and efficiency in harsh conditions.

Heavy-Duty Gate and Door Applications

Stainless steel weld-on hinges are frequently employed in heavy-duty gates, commercial doors, and security panels. Their high load-bearing capacity makes them indispensable for large-scale applications.

These hinges ensure stability and smooth operation in demanding settings, such as warehouses, factories, and high-security facilities.

For instance, special hinges with grease fittings enhance performance by reducing friction and extending the hinge’s lifespan.

Use in Trailer Ramps

Trailer ramps demand durable and reliable hardware to handle heavy loads during loading and unloading. Stainless steel weld-on hinges are ideal for this purpose, offering strength and resistance to wear.

Their seamless design ensures stability, which is crucial for trailers used in agriculture, construction, and logistics.

The use of weld-on hinges in ramps not only improves performance but also provides safety and efficiency in operation.

Applications in Steel Doors

Steel doors used in industrial and commercial buildings often rely on stainless steel weld-on hinges for their longevity and fire resistance.

These hinges offer a seamless and robust solution for secure door fastening, commonly seen in fire-rated doors and access control systems.

In applications requiring aesthetics and functionality, such as office spaces, piano hinges might be preferred for their sleek design and versatility.

Weld-On Hinges with Grease Fittings

Grease fittings in weld-on hinges allow for easy maintenance, reducing wear and enhancing performance over time. This feature is particularly valuable in heavy-use environments.

Such hinges are often used in industrial machinery, trailers, and gates, where reducing friction is critical to ensuring long-term operation.

Their innovative design combines functionality with practicality, ensuring a prolonged lifespan and reduced operational costs.

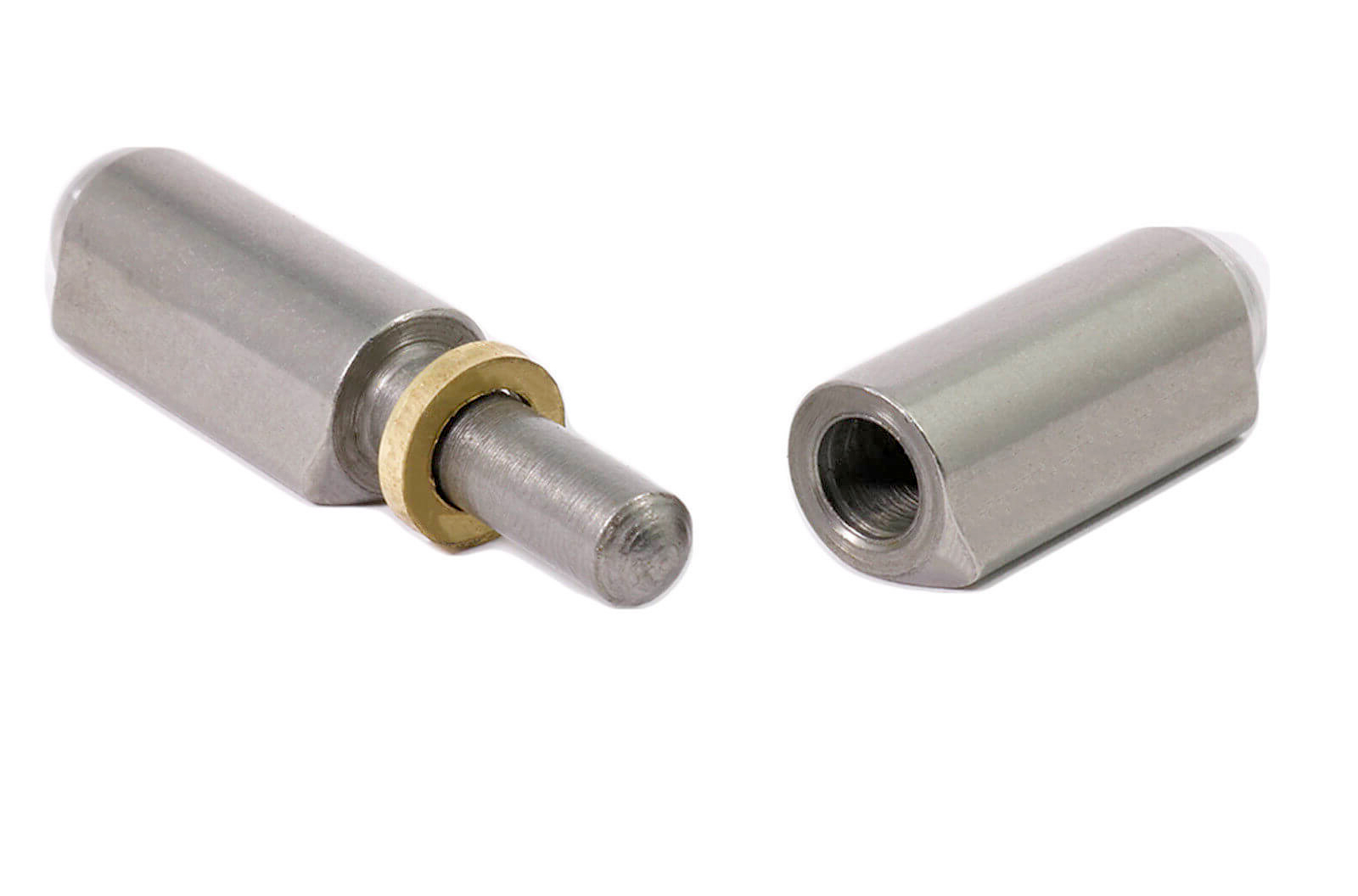

Bullet Weld-On Hinges and Their Uses

Bullet hinges, a specific type of weld-on hinge, are known for their compact design and high strength. These hinges are commonly used in gates, fences, and industrial enclosures.

Their cylindrical shape provides a streamlined appearance and reliable operation, especially in applications where space is limited.

For demanding conditions, bullet hinges with stainless steel construction provide unmatched durability and corrosion resistance.

Applications in Marine Environments

Marine environments pose unique challenges due to constant exposure to saltwater and humidity. Stainless steel weld-on hinges are ideal for these conditions, offering excellent resistance to corrosion.

These hinges are commonly used in ship doors, dockside equipment, and marine storage units, ensuring durability and performance in harsh settings.

For instance, heavy-duty hinges designed for marine use ensure reliable operation even in extreme weather.

Benefits in Heavy Industrial Use

Stainless steel weld-on hinges excel in heavy-duty industrial applications, such as loaders, excavators, and factory machinery. Their robust construction withstands intense stress and frequent use.

This makes them a trusted choice for manufacturers and operators looking to ensure safety and efficiency in their operations.

Whether in constant motion or static use, these hinges deliver outstanding performance and reliability.

Conclusion

Stainless steel weld-on hinges are indispensable in industrial, marine, and heavy-duty applications. Their durability, rust resistance, and seamless design make them essential across multiple industries.