Hinges serve as essential connectors that allow objects like doors, cabinets, and industrial equipment to pivot or swing smoothly. With each hinge type offering unique functionality, understanding the range of hinges available is key for selecting the right hinge for any application.

Various hinge types, including butt hinges, piano hinges, concealed hinges, and more, provide tailored support for doors, cabinets, and industrial installations. The best hinge type depends on the specific requirements for load-bearing, design, and application needs.

To better understand hinge options, here’s a breakdown of different hinge types and where they are best used.

Butt Hinges

Butt hinges are commonly used on doors and gates due to their strength and reliability.

Butt hinges consist of two leaves joined by a pin, allowing doors to swing smoothly. They’re widely used for residential and commercial doors, offering easy installation and strong support.

Butt hinges are durable and ideal for doors with frequent use. Available in standard and heavy-duty variations, they can be used in both residential and industrial applications. Heavy duty butt hinges, often made from stainless steel, support larger doors or industrial equipment requiring stability and resistance to wear.

Applications of Butt Hinges

- Residential Doors: Common in homes for their reliability.

- Industrial Equipment: Heavy duty variants used in industrial settings to support larger structures.

Continuous (Piano) Hinges

Continuous hinges, or piano hinges, are long hinges that run along the entire length of a surface, providing consistent support.

Continuous hinges evenly distribute the weight of heavy panels or doors, making them ideal for applications where stability is essential. They’re widely used in equipment cabinets, doors, and storage solutions.

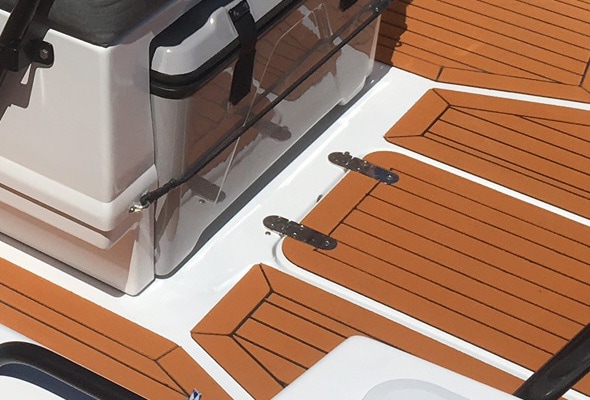

Due to their extended length, piano hinges are highly durable, especially in applications that involve frequent opening and closing. These hinges are particularly popular in the manufacturing of industrial equipment and marine hinges for reliable support in various environments.

Uses for Continuous Hinges

- Cabinet Doors: Ensures alignment and stability for heavy doors.

- Industrial Equipment: Durable for large access panels or cabinets, especially where frequent movement occurs.

Concealed Hinges

Concealed hinges, also known as European hinges, remain hidden when the door is closed, ideal for creating a clean look.

Concealed hinges are fully hidden when doors are shut, commonly used in cabinetry to enhance aesthetics. They often come with soft-close features for a smooth, quiet closing action.

Concealed hinges are often adjustable and may include a soft close hinge option, making them popular in high-end kitchen and bathroom cabinetry. These hinges provide a modern, streamlined look that’s both functional and visually appealing.

Where to Use Concealed Hinges

- Cabinets: Perfect for concealed door edges, commonly found in kitchens and offices.

- Furniture: High-end furniture design that values aesthetics and smooth operation.

Pivot Hinges

Pivot hinges support a door from the top and bottom, allowing it to pivot smoothly from a central point.

Pivot hinges provide a stable rotation from a fixed point, ideal for heavy, full-height doors in commercial spaces or as statement pieces in modern designs.

Pivot hinges are often used in commercial settings with heavy or oversized doors, offering extra stability by positioning hinges at the door’s top and bottom. In industrial settings, they can be paired with trailer door hinges for reinforced support.

Key Applications for Pivot Hinges

- Commercial Doors: Frequently used for heavy-duty doors in storefronts and lobbies.

- Revolving Doors: Common in high-traffic entryways for enhanced stability and function.

Strap Hinges

Strap hinges have long leaves that provide extra support, commonly seen on barn doors and gates.

Strap hinges feature decorative, elongated arms, which add both support and aesthetic value, making them ideal for outdoor gates and barn doors.

These hinges are often seen in rustic and outdoor applications due to their sturdy design. Available in a variety of finishes, strap hinges not only provide structural support but also enhance the visual appeal of traditional or industrial doors.

Usage for Strap Hinges

- Gates and Barn Doors: Commonly used on large, rustic gates and wooden doors.

- Heavy Industrial Doors: Adds strength and durability to doors in industrial settings.

Spring Hinges

Spring hinges contain an internal spring that enables automatic closure of doors.

Spring hinges offer self-closing functionality, making them ideal for gates, fire doors, and industrial spaces that require doors to close automatically.

Spring hinges are available in single-action and double-action varieties, allowing doors to swing in one or both directions. They are widely used in safety applications and for energy efficiency in climate-controlled spaces.

Applications for Spring Hinges

- Safety Doors: Common in fire and security doors to ensure closure.

- Gates and Access Panels: Useful for gates that need consistent closure.

Weld-On Hinges

Weld-on hinges are welded directly onto metal surfaces, ideal for heavy-duty applications.

Weld-on hinges are welded rather than screwed into place, providing robust support in industrial and heavy-duty applications, such as for trailer and cold storage room doors.

Manufactured from durable materials like steel or aluminum, weld-on hinges are often used in industrial hinge production bases for heavy gates, trailers, and equipment panels, especially in settings requiring high security and load capacity.

Ideal Uses for Weld-On Hinges

- Trailers and Gates: Provides the strength needed for heavy, high-use structures.

- Industrial Equipment: Secure attachment for high-load, frequent use panels.

Flush Hinges

Flush hinges sit within the frame without the need for mortising, suitable for lightweight doors.

Flush hinges provide a compact, gap-free fit for cabinet doors and lightweight applications, adding minimal bulk and visual distraction.

Flush hinges are popular in lightweight cabinetry and furniture where load-bearing is minimal. They’re also cost-effective and offer easy installation, making them a preferred choice for interior spaces with lightweight doors.

Where to Use Flush Hinges

- Interior Cabinets: Commonly found in light cabinet and furniture applications.

- Decorative Doors: Suitable for doors or panels where a discrete, compact hinge is desired.

Knife Hinges

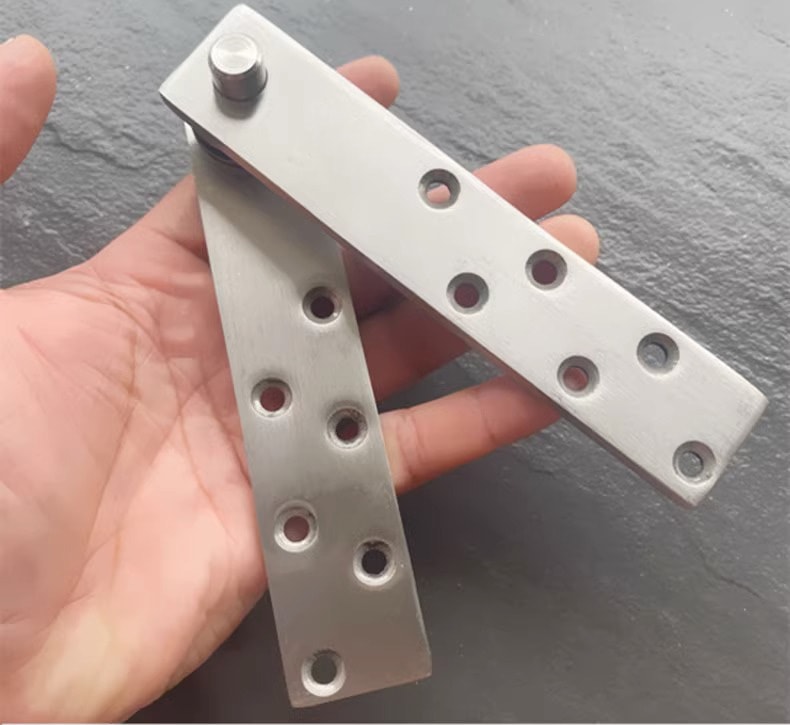

Knife hinges resemble the blade of a knife and are commonly used in fine furniture for smooth, hidden movement.

Knife hinges feature a thin, blade-like design that enables sleek, streamlined movement, making them popular in furniture and cabinetry.

Knife hinges are often used in custom cabinetry and luxury furniture due to their concealed design. Their sharp, thin profile provides smooth movement without visible hardware, creating a clean, refined look.

Popular Uses for Knife Hinges

- High-End Cabinetry: Perfect for custom furniture and hidden panel designs.

- Decorative Furniture: Adds sophistication to furniture with minimal hardware visibility.

Offset Hinges

Offset hinges move the door out and away from the frame, increasing clearance.

Offset hinges provide extra clearance by moving doors away from the frame, often used in accessibility-focused spaces to increase door opening width.

Offset hinges are useful for retrofitting existing doors to comply with accessibility standards, as they increase the effective door width without significant renovation. They’re commonly found in medical facilities and residential spaces that prioritize accessibility.

Typical Uses for Offset Hinges

- Accessible Doorways: Creates wider openings for wheelchairs or medical equipment.

- Medical and Public Buildings: Commonly used to increase clearance for accessibility.

Conclusion

Choosing the right hinge depends on the application, load, and appearance. Whether for cabinetry, industrial doors, or specialized applications like cold storage room hinges, understanding each hinge type ensures optimal performance.