What are the best hinges for external doors, especially in the industrial manufacturing sector? For many of us, hinges may seem like an insignificant part of our world. But when you’re in the manufacturing industry, you know how crucial the right hinge can be for the functionality and durability of your external doors.

Understanding the criticality of this selection, it’s safe to say that there’s no one-size-fits-all solution. Factors like the type of material, weight of the door, exposure to weather, and frequency of use all play a crucial role in this decision. But don’t worry. With a thorough understanding of your unique needs and an insight into the hinge market, we can steer towards the perfect choice for your industrial doors.

Let’s delve deeper, break this down and explore eight key topics that will help us choose the right hinges for your external industrial doors. Our shared quest for the perfect hinge begins now.

contact: [email protected]

Why is the choice of hinge important for external doors?

It’s essential to understand that the choice of hinge significantly impacts the functionality and longevity of your external doors. A poor choice can lead to wear and tear, door misalignment, and eventual replacement.

On the other hand, the right hinge will ensure smooth operation, longevity, and improved security of your external doors. In the industrial manufacturing sector, a broken or dysfunctional door can cause disruptions in workflow and productivity. Therefore, this choice is far from trivial; it is a decision that can affect your entire operation.

What types of hinges are commonly used?

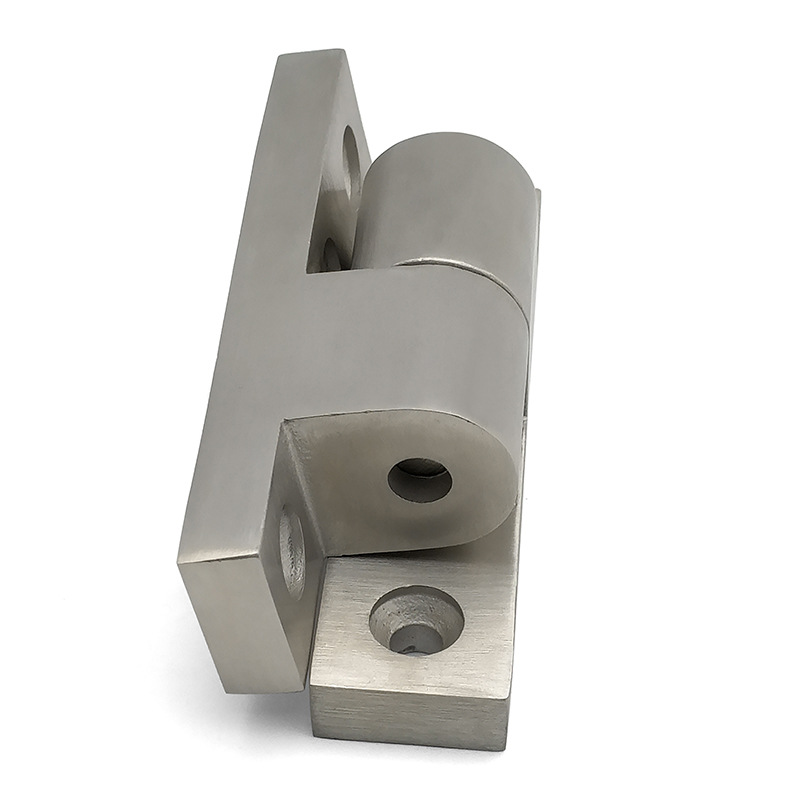

There are several types of hinges available, each offering unique benefits. The most common types include pivot hinges, continuous or piano hinges, and butt hinges. These hinges vary in their design, durability, and applications, making it necessary to understand their nuances before choosing one.

Pivot hinges, for example, are great for heavy doors and offer a sleek appearance. Continuous hinges run the entire length of the door, providing maximum support. Butt hinges are the most common type used for doors, and they come in various sizes and materials.

What material should the hinges be made of?

The material of the hinge is another key consideration when selecting the best hinges for external doors. Stainless steel, brass, and aluminum are some of the common materials used.

Stainless steel hinges are corrosion-resistant, making them a great choice for doors exposed to harsh weather conditions. Brass hinges, on the other hand, are known for their aesthetic appeal but may not be as durable. Aluminum hinges are lightweight and resistant to rust, but they may not support very heavy doors.

How does door weight affect hinge selection?

The weight of the door plays a significant role in deciding the type and size of the hinge. Heavy doors require robust hinges, often made of durable materials like stainless steel or brass.

Smaller, lighter doors may function well with smaller hinges, made of less sturdy material. It’s critical to understand the door’s weight to avoid overburdening the hinge, leading to premature wear and tear.

Are there specific hinges for weather-exposed doors?

Absolutely. External doors often face the wrath of the elements, so it’s crucial to consider weather-resistant hinges for these. Stainless steel hinges are an excellent choice because they resist corrosion, a common issue when exposed to harsh weather.

Galvanized steel hinges are another option as the galvanization process makes them more resistant to rust. Picking a hinge that can withstand the test of time and weather is crucial for the longevity of your external doors.

How does hinge maintenance factor into the selection process?

Maintenance is another factor to consider when choosing the best hinge. Some hinges require periodic lubrication to operate smoothly, while others are virtually maintenance-free.

Stainless steel and aluminum hinges are generally low-maintenance options. Their corrosion resistance reduces the need for frequent replacements. On the other hand, brass hinges might require more care to maintain their aesthetic appeal.

How does the frequency of door use affect hinge choice?

The frequency of use is a critical consideration when choosing a hinge. Doors that are frequently used require durable and sturdy hinges to withstand the constant wear and tear. Pivot hinges and continuous hinges are a good choice for such doors, as they offer superior durability.

On the other hand, doors that are rarely used can function well with basic hinge types, such as butt hinges. It’s essential to factor in the door’s usage frequency to ensure that your hinge can withstand the test of time and use.

What are the cost implications of different hinge choices?

Finally, cost is a critical factor when selecting the best hinge. More robust and durable hinges, such as stainless steel and pivot hinges, tend to be more expensive. However, their longevity and minimal maintenance can offset the initial cost in the long run.

On the other hand, more affordable options like butt hinges may incur more costs over time due to frequent replacements and maintenance. Therefore, while considering the cost, it’s crucial to think long-term and consider the total cost of ownership.

Conclusion

In conclusion, choosing the best hinges for your external doors in the industrial manufacturing sector is a complex decision involving many factors. There’s no one-size-fits-all solution. Understanding your unique requirements, considering factors like door weight, exposure to weather, frequency of use, maintenance needs, and cost implications can help you make an informed decision. Here’s to choosing the right hinge, and may our doors of opportunity always swing smoothly.

You might also be interested: