Mild Steel Weld-On Hinges provide a highly durable and cost-effective solution for heavy-duty applications. In industries such as manufacturing, logistics, and construction, these hinges offer unmatched strength and long-term performance, making them a reliable choice for critical machinery and equipment.

Mild Steel Weld-On Hinges are known for their strength, durability, and versatility in industrial applications. Their ability to withstand heavy loads, resist wear, and be welded directly onto surfaces makes them ideal for harsh and demanding environments.

Let’s explore why these hinges are essential for various industrial uses and how they provide added value in terms of cost-effectiveness, safety, and performance.

What Are Mild Steel Weld-On Hinges?

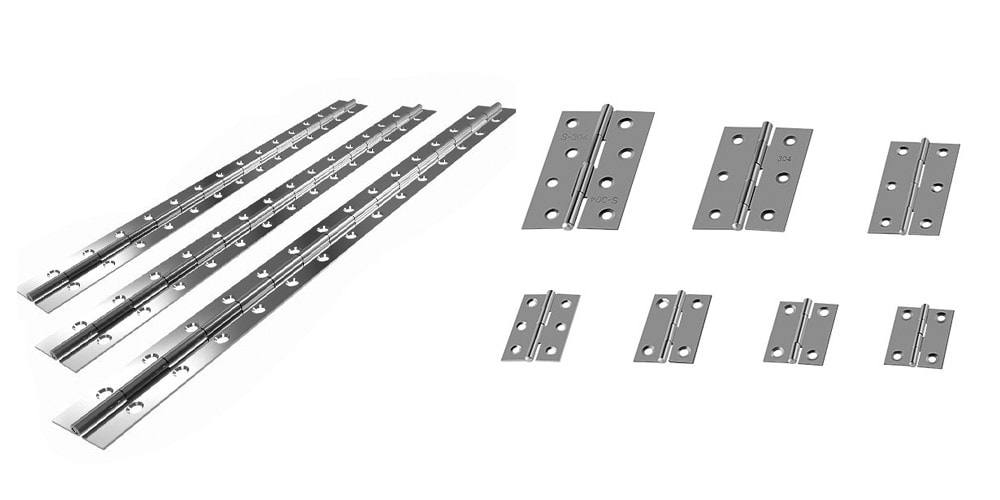

Mild Steel Weld-On Hinges are heavy-duty hinges designed to be welded directly onto machinery, doors, or other equipment. Made from mild steel, they offer a balance of strength, flexibility, and cost-effectiveness, making them ideal for heavy-duty applications where durability is a critical factor.

Mild Steel Weld-On Hinges are durable, customizable hinges welded directly onto surfaces. They are perfect for industrial applications that require strength and long-lasting performance in harsh environments.

Mild Steel Weld-On Hinges are used in a wide range of industries, such as transportation, manufacturing, and environmental testing. The steel provides excellent tensile strength, ensuring that these hinges can bear the weight and stress of large doors, machinery, and other heavy components. Unlike traditional bolted or screwed hinges, welded hinges offer a permanent and secure connection, which minimizes the risk of loosening or failure over time. These hinges are also customizable in terms of size, weight capacity, and configuration, making them highly adaptable to various industrial needs.

Because they are welded, these hinges are able to withstand significant stresses and environmental factors, such as vibration, heavy impacts, and exposure to extreme temperatures. Whether it’s in a trailer door, a cold storage room hinge, or a climatic test chamber hinge, Mild Steel Weld-On Hinges provide the security and durability required for the most demanding environments.

Why Are Mild Steel Weld-On Hinges Ideal for Heavy Duty Applications?

Mild Steel Weld-On Hinges are specifically designed to support heavy loads and resist wear and tear in extreme industrial conditions. They offer several key advantages, including increased strength and reliability, making them the preferred choice for applications that demand high performance.

The strength of Mild Steel Weld-On Hinges makes them ideal for heavy-duty applications. Their durability ensures they can handle significant weight and pressure over extended periods.

The unique construction of Mild Steel Weld-On Hinges allows them to bear large loads without bending or failing. For example, in industrial machinery or trailer door hinges, the hinges are exposed to significant forces. With a welded hinge, the connection between the hinge and the surface is much stronger than a bolted connection, ensuring the stability of the entire structure. The absence of screws or bolts means fewer points of potential failure, offering a more secure attachment.

In many industrial settings, equipment and machinery are subject to constant movement and vibration. This is especially true for heavy-duty hinges used in high-traffic areas or large equipment. The welded design of these hinges minimizes the risk of loosening over time, which is a common issue with traditional bolted hinges. By providing a stable and secure connection, Mild Steel Weld-On Hinges enhance the performance and longevity of the equipment.

What Are the Cost-Effectiveness and Durability Benefits of Mild Steel Weld-On Hinges?

Mild Steel Weld-On Hinges offer a unique balance of affordability and durability. While the initial cost may be slightly higher than non-welded hinges, the long-term savings on maintenance, repairs, and replacements make them an excellent investment for many industrial applications.

Mild Steel Weld-On Hinges provide a cost-effective solution for industries that need durable, long-lasting hinges for demanding applications. Their low-maintenance nature helps reduce overall operational costs.

The cost-effectiveness of Mild Steel Weld-On Hinges can be attributed to both their material and the installation process. Mild steel is an affordable material, especially when compared to marine hinges or aluminum hinges, which may be more expensive but are still less cost-effective for many industrial applications. Additionally, because these hinges are welded onto surfaces, there is no need for additional hardware like bolts or screws, which reduces installation time and cost.

Welded hinges are also highly durable, offering a long lifespan with minimal maintenance. In applications where hinges are exposed to heavy loads, harsh environments, or frequent movement, the reduced likelihood of failure significantly lowers long-term operational costs. This durability translates to fewer replacements, less downtime, and overall better performance, particularly in high-demand sectors such as logistics or industrial hinge production base operations.

How Do Mild Steel Weld-On Hinges Improve Safety in Industrial Settings?

Safety is a crucial concern in industrial environments, where equipment failures or accidents can lead to costly damages or injuries. Mild Steel Weld-On Hinges contribute to safety by providing a stable, permanent connection that reduces the risk of malfunction or failure.

Mild Steel Weld-On Hinges improve safety by ensuring a secure attachment to heavy machinery and equipment. Their welded design eliminates the risk of loosening or detachment over time.

In industries such as manufacturing, warehousing, and transportation, the integrity of equipment hinges is critical for safe operation. Mild Steel Weld-On Hinges are designed to withstand significant stress and movement without loosening, ensuring that doors, machinery, and other equipment function as intended without risk of failure. For example, detachable hinges or special hinges used in high-stress environments may fail if they are not properly secured, posing a safety risk. Welded hinges, however, offer more stability, preventing accidents or equipment malfunctions.

In the case of cold storage room hinges or climatic test chamber hinges, a failure in the hinge could compromise the entire structure. Welded hinges, by their nature, eliminate the potential for detachment, ensuring the safety and reliability of the equipment. Additionally, these hinges improve operational efficiency, as equipment will require fewer repairs and less frequent maintenance.

Conclusion

Mild Steel Weld-On Hinges offer an ideal solution for heavy-duty industrial applications, combining strength, durability, cost-effectiveness, and safety. Their ability to withstand harsh environments and provide long-term performance makes them a go-to choice for manufacturers and operators seeking reliable, low-maintenance hinge solutions. Whether used in trailer door hinges, piano hinges, or marine hinges, these welded hinges ensure that industrial machinery and equipment remain functional and safe for years to come.