Solar simulation chamber hinges are specialized hinges designed to withstand the harsh environmental conditions present in solar simulation chambers. These chambers are used to test the durability and performance of solar panels. And other solar-powered devices under extreme temperatures, humidity, and UV radiation. With the help of these hinges, the chamber doors can open and close smoothly and reliably. Ensuring accurate and efficient testing of solar-powered equipment. In this article, I will cover the concept, characteristics, uses, materials, and customization of these hinges.

What are Solar Simulation Chamber Hinges?

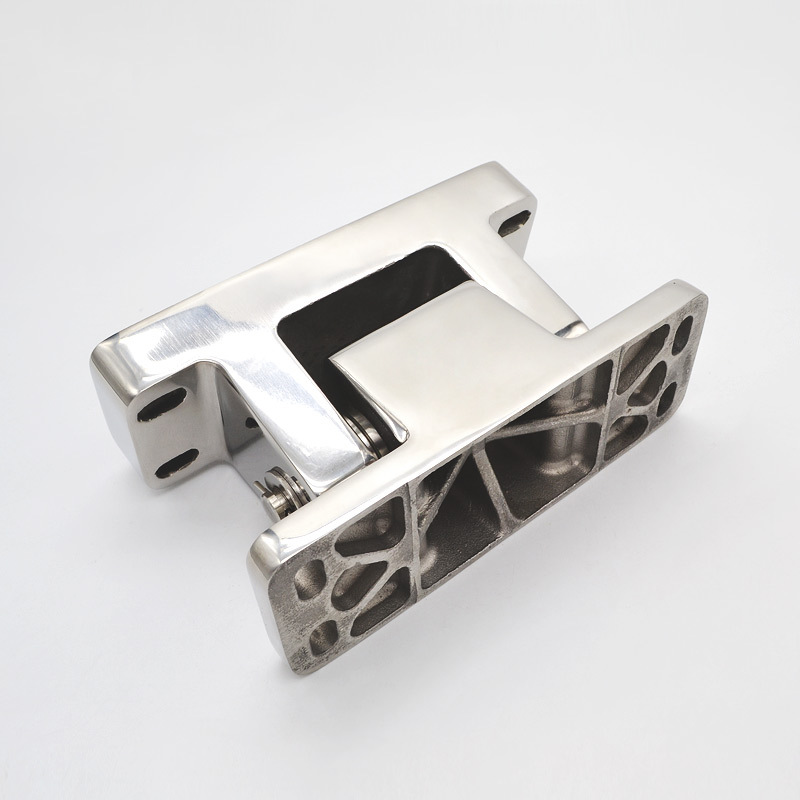

The first aspect to consider when discussing the features of hinges is their durability. These hinges must be able to withstand the harsh conditions of solar simulation chambers. They are typically made from materials such as stainless steel. Or other corrosion-resistant alloys to ensure that they do not deteriorate over time. Additionally, they are designed to be able to withstand extreme temperatures, humidity, and UV radiation. This makes them an ideal choice for use in solar simulation chambers. As they can hold up well under testing conditions and provide reliable performance.

Another important feature of solar simulation chamber hinges is their ability to provide a tight seal. These hinges are often used to secure doors and other access points in solar simulation chambers. And as such, it is important that they provide a tight seal to prevent the infiltration of outside air or moisture. This helps to maintain the stability of the testing environment and ensure that the results obtained from the testing are accurate. To achieve this, hinges are designed to fit snugly and securely. And they may even be equipped with additional seals or gaskets to further enhance their performance.

Characteristics of Solar Simulation Chamber Hinges

In addition to their use in solar simulation chambers, environmental chamber hinges are also essential components in a variety of other testing environments. These hinges are designed to provide reliable performance in conditions that are challenging for conventional hinges. For example, environmental chamber hinges are used in testing environments that simulate extreme weather conditions. Such as high winds, heavy rain, and extreme temperatures.

They are also used in aging test chamber hinges where products are exposed to a range of environmental stresses over extended periods to simulate their lifespan. In industrial door hinges, environmental chamber hinges are used to provide smooth and efficient operation in environments that may be subject to vibration, shock, or high levels of moisture. These hinges are also designed to be easy to install and maintain. Making them an ideal choice for use in a range of applications. Overall, environmental chamber hinges are a critical component for ensuring the reliability and longevity of products that are designed to function in harsh environmental conditions.

Uses of Solar Simulation Chamber Hinges

In addition to their use in solar simulation chambers, hinges share similarities with industrial door hinges in terms of their function and durability. Industrial door hinges are designed for use in heavy-duty applications. Such as warehouses and factories, where they are subjected to frequent use and exposure to harsh environments. Like solar simulation chamber hinges. They are constructed from high-quality materials that are resistant to corrosion and wear.

One key difference between industrial door hinges and hinges is their size and weight capacity. Industrial door hinges are typically much larger and able to support much heavier doors than solar simulation chamber hinges, which are designed for use with smaller, lighter chamber doors. However, both types of hinges must be able to provide smooth and reliable operation under demanding conditions. And must be able to withstand repeated use without failing or wearing down. By drawing on the strengths of both industrial door hinges and environmental chamber hinges. Solar simulation chamber hinges are able to provide reliable and durable operation in the most demanding of environments.

Materials Used in Chamber Hinges

In addition to their use in solar simulation chambers. These specialized hinges are also commonly used in aging test chambers. Aging test chambers are used to simulate the effects of time and wear on various materials and products. Including automotive parts, electronic devices, and medical equipment. The hinges used in these chambers must be able to withstand constant use and exposure to a variety of environmental conditions.

Aging test chamber hinges require the same level of durability and resistance to environmental factors as solar simulation chamber hinges. They are often made from the same high-quality materials. Such as stainless steel and aluminum, and coated with specialized coatings to protect against corrosion and other forms of damage. These hinges are also designed to provide smooth and reliable operation, even after extended use. They must be able to withstand the constant opening and closing of the chamber door. As well as exposure to extreme temperatures, humidity, and other environmental factors. Overall, aging test chamber hinges are crucial components of these testing systems, ensuring that the products and materials being tested can withstand the rigors of time and use.

Customization of Chamber Hinges

Customization is an important aspect of solar simulation chamber hinges as it allows them to be tailored to the specific requirements of various applications. The size and shape of the hinge can be adjusted to fit the dimensions of the chamber door, ensuring a perfect fit and proper functioning. The material of the hinge can also be customized depending on the needs of the application. For example, if the chamber will be used in a corrosive environment, a stainless steel hinge might be preferred to prevent corrosion and extend the lifespan of the hinge.

In addition to size, shape, and material, other customization options are also available for solar simulation chamber hinges. One such option is the ability to improve the functionality of the hinge. For example, a hinge can be designed to reduce noise or dampen vibrations, which can be particularly useful in applications where noise or vibration can be disruptive. Another customization option is improved sealing, which can prevent air or gas leakage from the chamber, ensuring that the testing environment is maintained at a consistent level. These customization options can help to enhance the performance and functionality of solar simulation chamber hinges, making them a valuable asset in the testing of solar-powered devices.