Industrial stainless steel hinges play a crucial role in various applications across diverse industries. These robust and reliable components offer durability, strength, and corrosion resistance, making them a popular choice for heavy-duty and high-demand environments. In this article, we will delve into the world of industrial stainless steel hinges, exploring their types, characteristics, applications, and installation techniques.

What are Industrial Stainless Steel Hinges?

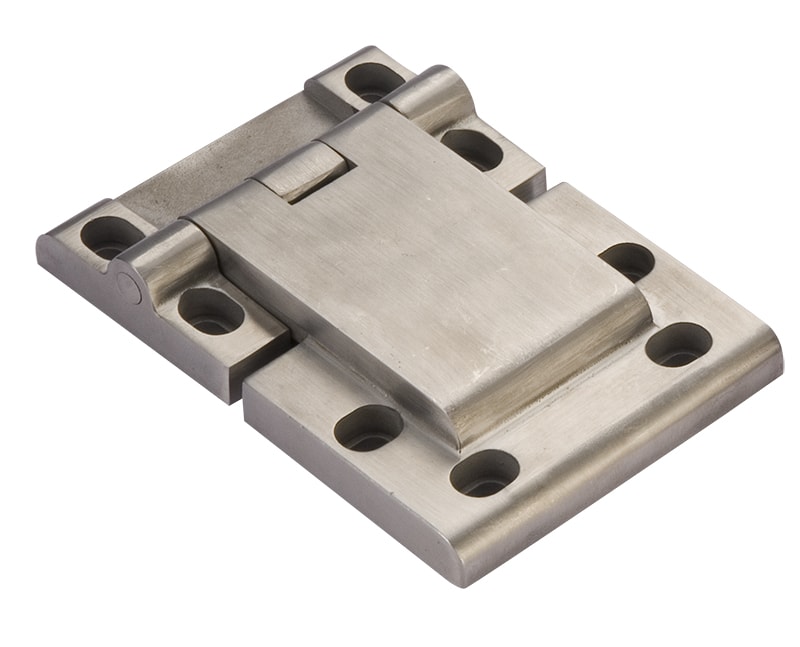

Industrial stainless steel hinges are specially designed hardware components used to facilitate the rotation or movement of doors, cabinets, gates, and other industrial equipment. They are manufactured using high-quality stainless steel alloys, known for their exceptional strength, longevity, and resistance to rust and corrosion. Unlike standard hinges, these hinges are engineered to withstand heavy loads, harsh environments, and repetitive usage.

What are the types of industrial stainless steel hinges?

- Continuous Hinges: Also referred to as piano hinges, continuous hinges are elongated strips of stainless steel that run the entire length of a door or panel. They provide consistent support and distribution of weight along the full length, making them ideal for heavy doors or large industrial enclosures.

- Butt Hinges: Butt hinges are the most common type of hinges. They consist of two symmetrical leaves connected by a pin, allowing rotation and movement of the door or gate. Butt hinges are available in various sizes and configurations, including plain, ball bearing, and rising options, catering to different load capacities and applications.

- Strap Hinges: Strap hinges feature a longer leaf attached to the door or gate, while the shorter leaf is affixed to the frame or wall. This design provides increased stability and weight-bearing capacity, making strap hinges suitable for heavy-duty applications such as industrial gates and entrance doors.

What are the characteristics of industrial stainless steel hinges?

- Corrosion Resistance: The hinges are made from corrosion-resistant alloys, such as 316 or 304 stainless steel. This property ensures their longevity and performance, even in demanding environments exposed to moisture, chemicals, or extreme temperatures.

- Strength and Durability: These hinges are constructed to withstand heavy loads and repetitive use, offering exceptional strength and durability. They can withstand the rigors of industrial settings, providing reliable performance and long-lasting functionality.

- Smooth Operation: These hinges are engineered with precision, allowing smooth and frictionless operation. They ensure effortless opening and closing of doors, minimizing wear and tear on the hinge and associated components.

Applications of industrial stainless steel hinges?

Industrial stainless steel hinges find extensive applications across a wide range of industries, including:

- Aerospace and Defense: These hinges are employed in aircraft doors and access panels. They are also utilized in military equipment, emphasizing the significance of durability and reliability.

- Industrial Machinery: They are employed in heavy machinery, industrial cabinets, and enclosures. Providing robust support and easy access for maintenance and repairs.

- Marine and Offshore: These hinges are corrosion-resistant. Making them suitable for marine and offshore applications such as boat doors, hatches, and access panels.

- Automotive and Transportation: Hinges in this sector are used for vehicle doors, engine compartments, truck toolboxes, and cargo doors. Ensuring secure and efficient operation.

How to Install Industrial Stainless Steel Hinges?

Installing the hinges requires careful attention to detail to ensure proper functionality and longevity. Follow these steps for a successful installation:

- Prepare the Door and Frame: Ensure the door and frame are clean and free from debris or obstructions. Measure and mark the hinge locations on both the door and frame.

- Align the Hinges: Position the hinges on the door and frame, aligning them accurately with the marked locations. Secure the hinges in place using suitable screws or bolts.

- Check Alignment and Clearance: Verify that the hinges are properly aligned and the door swings smoothly without any interference or binding. Adjust the hinge position if necessary.

- Secure Hinge Components: Tighten the screws or bolts firmly to secure the hinges to the door and frame. Avoid overtightening, as it may affect the hinge’s operation.

- Test the Door Operation: Open and close the door several times to ensure smooth movement and proper alignment. Make any necessary adjustments for optimal performance.

Conclusion:

Industrial stainless steel hinges offer exceptional strength, corrosion resistance, and durability, making them indispensable components in various industrial applications. By understanding the types, characteristics, applications, and installation techniques, professionals can select and utilize these hinges effectively. Ensuring reliable and long-lasting performance in demanding environments.