You may be looking for an industrial hinge for your equipment installation. But before you do, it’s important to know a few things about industrial hinges. This will help you find the right product more quickly. For example, you should at least know what an industrial hinge is first.

Industrial hinges are hardware fittings that are professionally used on the doors of various types of industrial equipment. Due to the wide variety of industrial equipment. So for different equipment doors, customized industrial hinges are usually used.

If you want to learn more about industrial hinges, then follow me and read on.

Characteristics of Industrial Hinges:

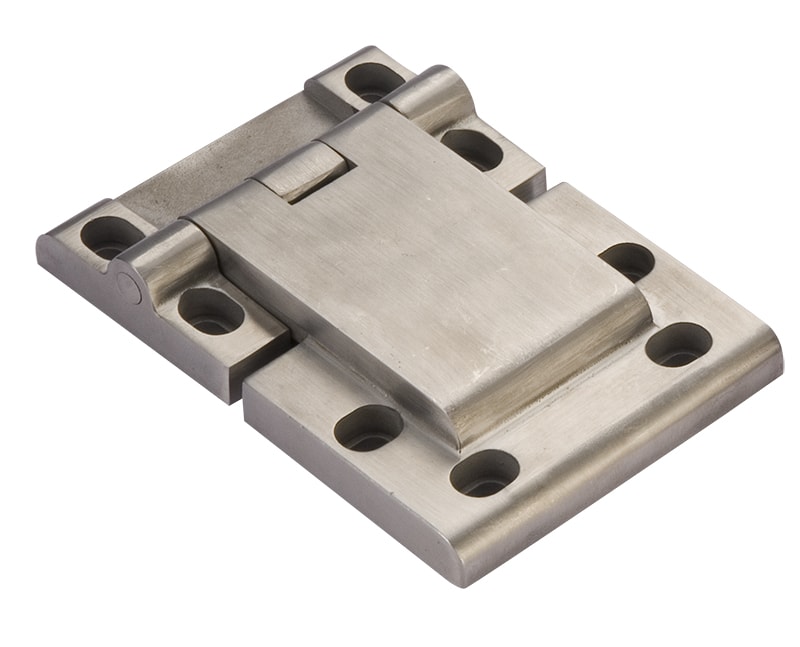

Industrial hinges are essential components widely used in various applications due to their robust features and reliable performance. When considering industrial hinges for specific projects, several crucial characteristics should be taken into account:

- Load-Bearing Capacity: Industrial hinges are designed to withstand heavy loads and provide reliable support for doors, gates, panels, and other industrial structures.

- Structural Appearance: These hinges come in a variety of styles and designs, catering to diverse aesthetic preferences and structural requirements.

- Surface Treatments: Industrial hinges are often treated with protective coatings, such as galvanization or powder coating, to enhance their durability and corrosion resistance, especially in challenging environments.

- Corrosion Resistance: Given their common use in industrial settings exposed to harsh elements, high-quality industrial hinges are built to resist corrosion, ensuring long-lasting performance even in demanding conditions.

Moreover, manufacturers continuously improve hinge designs to cater to specific industries, leading to innovations like concealed hinges, adjustable hinges, and specialized hinges for unique applications. The versatility and durability of industrial hinges make them indispensable in various sectors, including manufacturing, construction, transportation, and more.

Applications of Industrial Hinges:

Industrial hinges find a multitude of applications across different industries, owing to their strength, flexibility, and reliability. Some common uses include:

- Industrial Machinery: Industrial hinges play a vital role in heavy machinery, allowing access to crucial components and facilitating maintenance tasks.

- Transportation: Hinges are utilized in the automotive and aerospace sectors for doors, hatches, and control surfaces.

- Architectural Applications: They are employed in building doors, gates, windows, and entryways, providing smooth and secure movement.

- Cabinetry and Furniture: Industrial hinges enable smooth opening and closing of cabinets, cupboards, and furniture items in both residential and commercial settings.

- Outdoor Structures: They are used in outdoor installations like fences, gates, and access panels, withstanding varying weather conditions.

The diverse applications of industrial hinges highlight their significance in different industries, where their reliable performance contributes to the seamless functioning of machinery, structures, and equipment.

Differences between Industrial Hinges and Architectural Hinges:

While both industrial hinges and architectural hinges serve the purpose of facilitating movement in different structures, several key differences set them apart:

- Design and Aesthetics: Architectural hinges are often designed to be more visually appealing, with an emphasis on aesthetics to complement the overall look of doors and cabinets. Industrial hinges, on the other hand, prioritize functionality and durability over decorative elements.

- Load-Bearing Capacity: Industrial hinges are engineered to bear heavier loads, making them suitable for industrial machinery and heavy-duty applications. Architectural hinges are typically designed for standard doors and lighter structures.

- Exposure to Elements: Industrial hinges are designed to withstand harsh environmental conditions, such as extreme temperatures, moisture, and chemical exposure, making them ideal for outdoor and industrial applications. Architectural hinges are more commonly used in interior settings where they are protected from severe weathering.

- Construction Material: While both types of hinges can be made from various materials, industrial hinges often incorporate more robust materials like stainless steel or hardened alloys, providing enhanced strength and resistance to wear and tear.

These distinctions make it crucial to choose the right type of hinge based on the specific requirements of the intended application, ensuring optimal performance and longevity.

How to Choose an Industrial Hinge:

Selecting the appropriate industrial hinge for a particular project requires careful consideration of various factors, including:

- Structural Compatibility: Assess the dimensions and weight of the door or panel to ensure the hinge can adequately support the load.

- Functionality: Determine the type of movement required, whether it’s a standard swing, concealed pivot, or continuous hinge, based on the door’s purpose and design.

- Load Capacity: Choose a hinge that can handle the anticipated load without compromising performance.

- Environmental Conditions: Consider the exposure of the hinge to weather, chemicals, or extreme temperatures and opt for a hinge with suitable corrosion-resistant properties.

- Installation: Ensure the hinge is compatible with the installation process and the material of the supporting frame or structure.

By carefully evaluating these aspects, you can confidently select an industrial hinge that meets your project’s specific needs, ensuring reliable and long-lasting operation.

Recommended Industrial Hinge Manufacturers:

Next, I will present you with a list of manufacturers that produce industrial hinges. It took me 3 hours to collect and organize, I hope it will be useful for you.

IHINGES.COM:

iHinges.com is a leading and trusted manufacturer specializing in industrial hinges. With a focus on delivering top-notch quality, their extensive range of hinges caters to diverse industrial applications. Offering innovative designs, robust construction, and exceptional corrosion resistance, iHinges.com is committed to providing reliable and efficient solutions to meet the unique needs of its customers.

SD Products:

SD Products is a reputable manufacturer known for its wide selection of industrial hinges and hardware solutions. With a focus on excellence and reliability, they serve various industries, including aerospace, automotive, and marine, offering high-performance hinges built to withstand demanding conditions. Their commitment to quality and customer satisfaction makes them a preferred choice for industrial hardware needs.

Sugatsune:

Sugatsune is a globally recognized manufacturer that excels in providing a diverse range of industrial hardware solutions, including hinges. With a focus on innovation and functionality, their high-quality hinges cater to a wide array of applications, offering reliable and durable performance. Trusted by industries worldwide, Sugatsune remains committed to delivering cutting-edge products that meet the evolving needs of its customers.

Kason Industries:

Kason Industries is a leading manufacturer of industrial hinges and hardware solutions. With a rich history of expertise, they specialize in providing high-quality hinges for diverse industries, ensuring smooth functionality and durability. Committed to innovation and customer satisfaction, Kason Industries continues to be a trusted choice for industrial hardware needs worldwide.

Coni Press:

Coni Press is a reputable manufacturer known for its expertise in producing industrial hinges and precision-engineered hardware components. With a focus on cutting-edge technology and quality craftsmanship, they offer a wide range of hinges designed to meet the specific demands of various industries. With a commitment to reliability and innovation, Coni Press remains a preferred choice for industrial hinge solutions worldwide.

Kiesler Machine:

Kiesler Machine Inc. is a comprehensive and innovative manufacturer specializing in industrial hinges and hardware solutions. With a strong focus on precision engineering and advanced technology, they offer a wide selection of high-quality hinges to cater to diverse industrial applications. From custom solutions to standard products, Kiesler Machine Inc. is dedicated to meeting the unique needs of its customers and delivering reliable, efficient, and durable hinge solutions.

Monroe Engineering:

Monroe Engineering is a reputable and established manufacturer specializing in industrial hinges and hardware components. With decades of experience, they offer a vast range of hinge solutions for various industries, ensuring top-notch quality and performance. Committed to customer satisfaction, Monroe Engineering continues to be a trusted source for reliable and innovative hinge products worldwide.

How to Customize an Industrial Hinge:

- Initial Inquiry:

The process begins with the customer contacting your factory with specific requirements for the custom hinge. It’s essential to gather all relevant details, such as dimensions, load-bearing capacity, material preferences, and any special features needed.

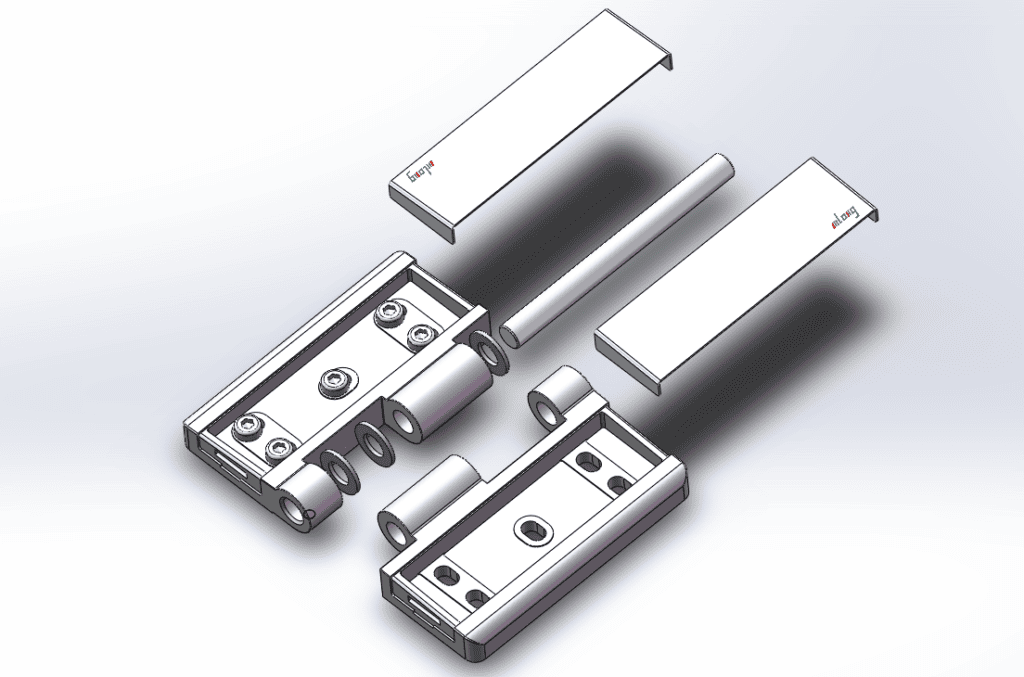

- Design and Engineering:

Your factory’s engineering team will work closely with the customer to create a detailed design for the custom hinge. This stage involves reviewing the specifications, conducting feasibility studies, and ensuring the design aligns with the intended application.

- Prototype Development:

Based on the agreed-upon design, your factory will produce a prototype of the custom hinge. The customer will have the opportunity to evaluate the prototype’s performance, fit, and functionality before proceeding to mass production.

- Testing and Validation:

The prototype undergoes rigorous testing to ensure it meets the desired performance standards and safety requirements. Any necessary adjustments or improvements are made at this stage.

- Material Selection:

Once the prototype is approved, the customer and your factory will finalize the material selection. Depending on the application and environmental conditions, a suitable material with the required strength and corrosion resistance will be chosen.

- Mass Production:

With the design and materials finalized, your factory will proceed with mass production of the custom hinges. The production process adheres to strict quality control measures to maintain consistency and product excellence.

- Surface Treatment and Finishing:

Depending on customer preferences and application needs, surface treatments such as galvanization, and powder coating. Or plating may be applied to enhance the hinge’s durability and aesthetics.

- Quality Inspection:

Before shipment, each custom hinge undergoes thorough quality inspection to ensure it meets all specified requirements and matches the approved prototype.

- Packaging and Delivery:

Your factory will package the custom hinges securely to prevent damage during transit. Timely delivery to the customer’s location is arranged as per the agreed-upon schedule.

- After-Sales Support:

Your factory provides ongoing support to the customer, including addressing any queries or issues that may arise post-delivery. This commitment to excellent customer service ensures a successful and satisfying custom hinge experience.

Conclusion:

Industrial hinges serve as critical components in a wide range of applications, providing support, movement, and security to various structures and equipment. When selecting industrial hinges, it is essential to consider factors such as load-bearing capacity, environmental resistance, and structural compatibility. By choosing reputable manufacturers like ihinges.com and considering customization