In the industrial sector, hinges play a crucial role in providing stability, strength, and functionality to various equipment and structures. Among the different types of hinges available, heavy-duty pin hinges stand out for their exceptional performance in demanding industrial applications. In this comprehensive guide, we will delve into the concept, advantages, materials, design features, selection criteria, installation and maintenance guidelines, safety considerations, troubleshooting, and real-life industrial applications of heavy-duty pin hinges.

Understanding heavy-duty Pin Hinges

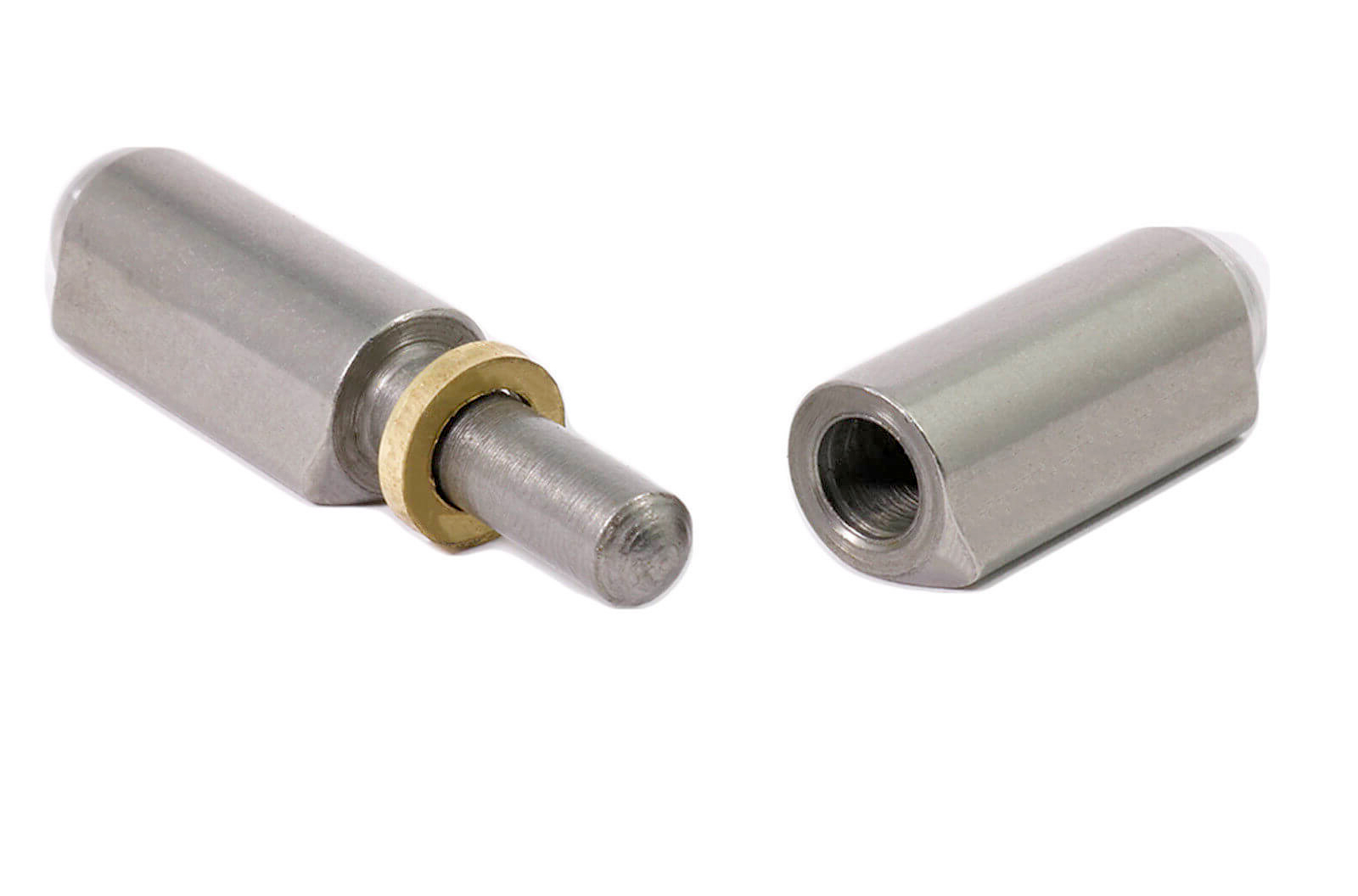

The hinges are robust and reliable hinge mechanisms specifically designed for industrial applications. These hinges are engineered to withstand heavy loads, extreme conditions, and repetitive use. They are commonly used in industrial settings where durability and strength are paramount. heavy-duty pin hinges feature a pin mechanism that allows for smooth rotational movement while providing exceptional support and stability.

Advantages of heavy-duty Pin Hinges

When compared to other hinge types, the hinges offer several distinct advantages. Firstly, their durability is unparalleled, ensuring long-lasting performance in industrial environments. They can withstand constant stress, vibrations, and heavy loads without compromising functionality. Additionally, heavy-duty pin hinges exhibit exceptional load-bearing capacity, making them ideal for equipment and structures that require robust support. Furthermore, these hinges are highly resistant to wear and tear, reducing the need for frequent replacements and maintenance.

Common Applications of Heavy-duty Pin Hinges in the Industrial Sector

heavy-duty pin hinges find extensive use in various industrial applications. They are commonly employed in heavy machinery, such as cranes, excavators, and forklifts, where their sturdy construction and load-bearing capabilities are essential. These hinges are also utilized in gates, access panels, and enclosure doors, ensuring smooth operation and reliable security. Additionally, the hinges are prevalent in manufacturing equipment, industrial cabinets, and heavy-duty toolboxes.

Materials Used in The Hinges

Manufacturers use high-quality materials to ensure the strength and durability of the hinges. Commonly used materials include:

1. Steel: Steel is a popular choice due to its exceptional strength and resistance to impact and corrosion. Hinges made from steel can withstand heavy loads and harsh environments.

2. Stainless Steel: Stainless steel offers excellent corrosion resistance, making it suitable for applications where exposure to moisture, chemicals, or extreme temperatures is a concern.

3. Brass: Brass hinges provide a balance between strength and aesthetics. They are often used in applications where both functionality and appearance are important.

Design Features and Components of The Hinges

Heavy-duty pin hinges incorporate specific design features and components to ensure their superior performance. Key elements include:

1. Pin Type: the hinges may feature fixed or removable pins. Removable pins allow for easier installation, maintenance, and disassembly if necessary.

2. Bearing Type: These hinges often employ high-quality bearings, such as ball bearings or thrust bearings, to facilitate smooth rotation and minimize friction.

3. Mounting Options: the hinges can be mounted using various methods, including welding, bolting, or screwing, depending on the specific application requirements.

Factors to Consider When Selecting Heavy-duty Pin Hinges

When choosing heavy-duty pin hinges for industrial applications, several factors should be taken into account:

1. Load Capacity: Assess the anticipated load and ensure the selected hinges can handle the weight and stress involved.

2. Environmental Conditions: Consider the environmental factors the hinges will be exposed to, such as temperature, humidity, chemicals, or dust, and choose hinges that can withstand those conditions.

3. Installation Requirements: Evaluate the installation process and ensure the hinges are compatible with the equipment or structure in question.

4. Maintenance Considerations: Take

into consideration the maintenance requirements of the hinges and select those that align with the available resources and maintenance schedules.

Proper Installation and Maintenance of Pin Hinges

To maximize the performance and lifespan of the hinges, proper installation, and regular maintenance are essential. Here are some guidelines:

1. Installation: Follow the manufacturer’s instructions and ensure the hinges are securely and correctly installed, using appropriate fasteners and techniques.

2. Lubrication: Apply a high-quality lubricant to the hinges periodically to reduce friction and ensure smooth operation. This will help prevent premature wear and extend the hinge’s lifespan.

3. Inspection: Regularly inspect the hinges for signs of damage, misalignment, or excessive wear. Replace any damaged or worn hinges promptly to maintain optimal performance.

Safety Considerations and Standards for Pin Hinges

In the industrial sector, safety is paramount. heavy-duty hinges must adhere to industry-specific safety regulations and standards. Compliance ensures that the hinges meet the required quality and performance criteria, minimizing the risk of accidents or failures.

Troubleshooting and Common Issues with Pin Hinges

Despite their durability, heavy-duty pin hinges may encounter issues over time. Here are some common problems and possible solutions:

1. Misalignment: If hinges become misaligned, realign and adjust them to ensure smooth operation.

2. Stiffness: Lubricate the hinges and check for any obstructions or debris that may be causing stiffness. Clean or replace as necessary.

3. Excessive Noise: Noisy hinges can indicate insufficient lubrication or worn components. Apply lubricant or replace worn parts to reduce noise.

Case Studies: Real-Life Industrial Applications of Heavy-duty Pin Hinges

Presenting real-life case studies demonstrates the effectiveness of the hinges in various industrial applications. Highlight specific industries and projects where these hinges have proven to be reliable, durable, and beneficial.

Conclusion

heavy-duty pin hinges play a crucial role in the industrial sector, providing strength, stability, and reliability in demanding applications. Their exceptional load-bearing capacity, durability, and resistance to wear and tear make them the preferred choice for heavy machinery, gates, access panels, and other industrial equipment. By considering factors such as materials, design features, installation requirements, and maintenance considerations, industrial professionals can select the most suitable heavy-duty pin hinges for their specific applications. The correct installation, regular maintenance, and adherence to safety standards ensure optimal performance and safety in the industrial environment.