Environmental aging test chamber hinges are critical for reliable equipment performance. Poor-quality hinges can result in chamber malfunction, leading to inaccurate test results and costly repairs. Opting for durable, high-quality hinges ensures long-lasting performance and minimizes downtime in testing operations.

Environmental aging test chamber hinges are specially designed to withstand extreme temperatures, humidity, and other environmental conditions, ensuring smooth operation and accurate testing results in climatic test chambers.

These hinges play a crucial role in maintaining the chamber’s integrity during rigorous testing cycles.

Understanding Environmental Aging Test Chamber Hinges

Environmental aging test chambers are used to simulate harsh environmental conditions such as extreme temperatures, humidity, and UV exposure. The hinges used in these chambers must withstand continuous exposure to these elements without failure. Unlike regular hinges, environmental aging test chamber hinges are specifically engineered to endure the unique challenges presented by the testing environment.

High-quality hinges contribute to the chamber’s longevity by providing smooth operation even under extreme conditions. Whether it’s repeated opening and closing or being exposed to corrosive elements, these hinges ensure that the test chamber remains sealed properly, preventing leaks or fluctuations that could affect the accuracy of the tests.

Importance of High-Quality Hinges in Environmental Aging Test Chambers

The quality of hinges in an environmental aging test chamber directly impacts the chamber’s overall functionality. Poor-quality hinges are prone to rusting, warping, or breaking under harsh conditions, which compromises the chamber’s ability to simulate accurate environmental conditions. Inaccurate tests can lead to faulty conclusions, product failures, and ultimately, financial losses for manufacturers.

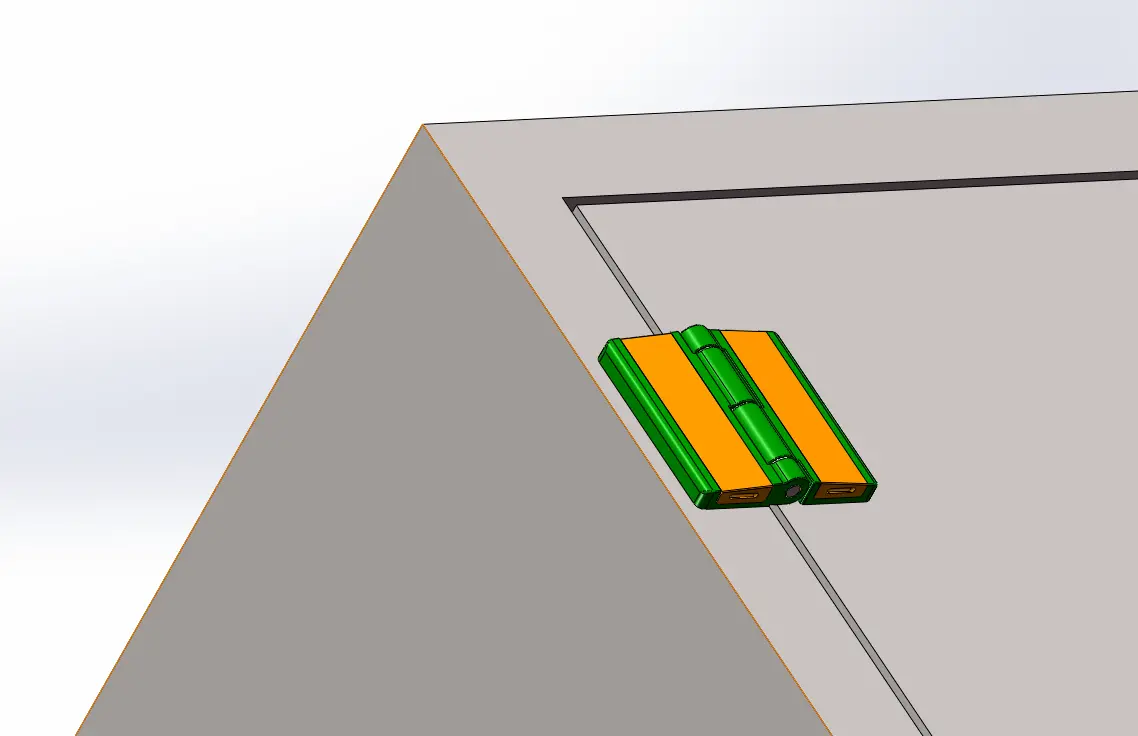

Choosing hinges that are made from corrosion-resistant materials, such as stainless steel or specialized alloys, ensures durability and reliability. These materials are designed to withstand not only temperature extremes but also the high levels of moisture and corrosive elements that can be present in aging test environments. This makes them essential for industries that depend on precise environmental testing.

Key Features of Environmental Aging Test Chamber Hinges

- Corrosion Resistance:

Environmental aging test chamber hinges are typically constructed from materials such as stainless steel or aluminum, which offer superior resistance to corrosion. These materials ensure that the hinges remain functional even after prolonged exposure to moisture, chemicals, or other corrosive substances present in the testing environment. - Temperature Resistance:

Test chambers often subject products to extreme temperatures, both hot and cold, to determine their durability. Hinges used in these chambers must operate smoothly at a wide range of temperatures without losing structural integrity. High-quality hinges are tested for performance at both ends of the temperature spectrum, ensuring they remain functional throughout the chamber’s operational life.

The Role of Hinges in Ensuring Accurate Testing

One of the most critical aspects of environmental aging test chambers is maintaining a controlled environment. Even a slight change in temperature or humidity can skew results. Hinges are essential in ensuring the chamber remains sealed and operational, preventing any air leaks or temperature fluctuations that could compromise the testing conditions.

Reliable hinges also contribute to minimizing the risk of equipment failure during testing, which can delay projects and increase operational costs. By ensuring that the doors of the test chamber can open and close without hindrance and that they remain properly sealed, high-quality hinges guarantee that testing proceeds without interruptions or inaccuracies.

How to Choose the Right Hinges for Environmental Aging Test Chambers

When selecting hinges for environmental aging test chambers, it’s crucial to consider several factors:

- Material Durability:

The materials used for the hinges should be resistant to corrosion, wear, and fatigue. Stainless steel and aluminum alloys are popular choices due to their long-lasting performance in harsh environments. - Load Capacity:

Hinges should be able to support the weight of the chamber doors, which can be heavy due to insulation and other materials. Choosing hinges with a suitable load-bearing capacity ensures smooth door operation over time. - Customization Options:

Since test chambers vary in size and design, the hinges may need to be customized to fit specific requirements. Custom hinges allow for better performance and ensure a perfect fit, reducing the risk of malfunction.

Applications of Environmental Aging Test Chamber Hinges

Environmental aging test chamber hinges are essential in industries where product durability and performance need to be tested under extreme conditions. Key applications include:

- Automotive Testing:

Hinges play a crucial role in environmental chambers used to test vehicle components. From testing the durability of exterior materials to simulating long-term exposure to UV rays and temperature changes, high-quality hinges ensure the test chambers function flawlessly. - Electronics and Aerospace:

Electronic components and aerospace equipment often undergo stringent environmental testing. Hinges that can endure continuous cycling in extreme conditions help maintain the integrity of these test chambers, ensuring that electronic components and aerospace parts are accurately tested for reliability.

Conclusion

Environmental aging test chamber hinges are essential components that ensure the accurate and reliable performance of testing chambers. Selecting high-quality, durable hinges that can withstand extreme environmental conditions is crucial for maintaining test accuracy and prolonging the lifespan of the chamber.