As an industrial manufacturing company, our focus lies on producing high-quality ball bearing hinges for exterior doors, an essential component in the construction of robust and reliable doors. These hinges play a crucial role in ensuring smooth and effortless door movement, contributing to the overall functionality and safety of various industrial facilities.

In this blog post, I will delve into the world of ball bearing hinges for exterior doors, exploring their importance, benefits, applications, and factors to consider when selecting the right hinges for specific industrial needs.

What are Ball Bearing Hinges for Exterior Doors?

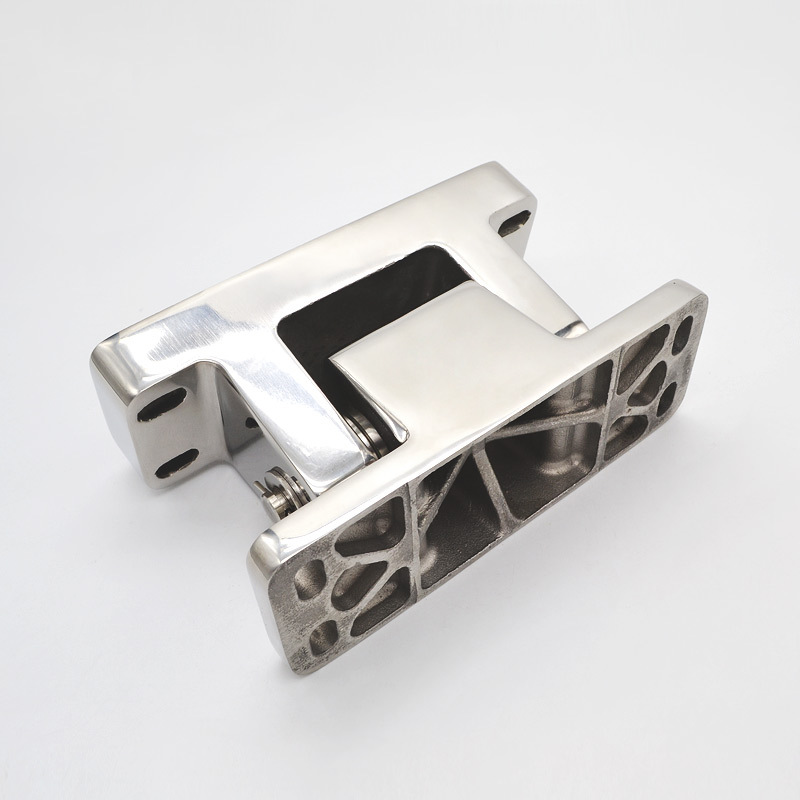

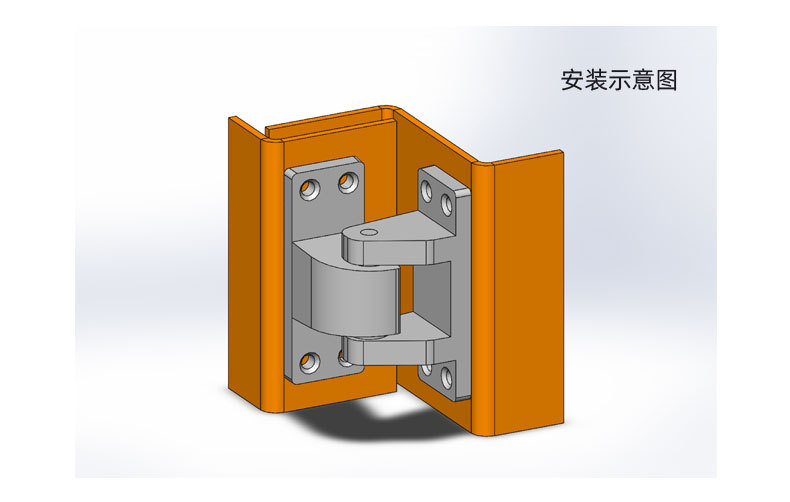

Ball bearing hinges, a type of mechanical bearing, are designed with small steel balls sandwiched between the hinge knuckles. This ingenious design allows the hinge to rotate smoothly and reduces friction, making it ideal for heavy exterior doors. The ball bearings also enhance the durability and lifespan of the hinges, ensuring they can withstand frequent use and exposure to harsh weather conditions.

When it comes to the industrial manufacturing sector, ball bearing hinges find extensive use in various applications, such as large warehouse doors, factory entrances, industrial equipment enclosures, and transportation infrastructure. These hinges facilitate easy and noiseless opening and closing of heavy-duty doors, contributing to enhanced operational efficiency and worker safety.

Ball bearing hinges are a crucial component in ensuring the smooth and efficient operation of industrial doors, which can be substantial and challenging to maneuver. These hinges effectively distribute the door’s weight, preventing sagging and potential damage over time. Their sturdy construction and ability to withstand heavy loads make them ideal for exterior doors in the industrial manufacturing sector.

To maintain readers’ interest, let’s dive deeper into the benefits that ball bearing hinges offer.

Exceptional Load-Bearing Capacity

One of the primary advantages of ball bearing hinges for exterior doors is their exceptional load-bearing capacity. In industrial settings, where doors might be oversized or equipped with heavy machinery, these hinges provide unparalleled support. The ball bearings distribute the weight evenly, preventing any undue stress on the door or its frame.

This load-bearing capacity not only enhances the door’s longevity but also minimizes the need for frequent repairs or replacements, leading to cost savings for industrial manufacturers. With doors operating smoothly, workers can move equipment and goods with ease, streamlining daily operations and enhancing productivity.

Smooth and Silent Operation

In an industrial environment, noisy doors can be disruptive and inconvenient. Ball bearing hinges, with their low-friction design, ensure a smooth and almost silent door operation. This feature is particularly advantageous in industrial facilities where minimal disturbance is critical, such as research labs, testing centers, or high-precision manufacturing areas.

The reduced friction also contributes to energy efficiency, as it requires less force to open and close the doors. This can result in a noticeable decrease in energy consumption and subsequent cost savings for industrial facilities.

Corrosion and Weather Resistance

Industrial environments can be harsh, with exposure to moisture, dust, and other corrosive elements. Ball bearing hinges are typically constructed from durable materials, such as stainless steel or brass, which offer excellent resistance to corrosion and weathering.

This resistance to environmental factors ensures that the hinges remain fully functional and retain their smooth operation over extended periods. As a result, industrial manufacturers can rely on these hinges to provide consistent performance, even in demanding conditions.

Enhanced Security and Safety

In industrial settings, security and safety are paramount. Ball bearing hinges contribute to both aspects by providing added stability and security to exterior doors. These hinges are less susceptible to tampering, making it difficult for unauthorized personnel to gain access to restricted areas.

Additionally, the smooth operation of ball bearing hinges reduces the risk of accidents caused by doors sticking or slamming shut unexpectedly. This feature ensures the safety of workers and minimizes the potential for workplace injuries.

Ease of Installation and Maintenance

Installing ball bearing hinges for exterior doors is relatively straightforward, especially when working with qualified professionals. The hinges come in various sizes and configurations to accommodate different door types and weights.

Moreover, these hinges require minimal maintenance due to their durable construction and low-friction design. Routine lubrication is typically all that is needed to keep the hinges operating smoothly for extended periods.

Versatility in Design and Finish

For industrial manufacturers seeking aesthetic appeal along with functionality, ball bearing hinges offer a range of design options. They are available in various finishes, such as brushed or polished, to complement the overall door design.

Additionally, some hinges have concealed bearing mechanisms, providing a sleek and modern appearance. These design options enable industrial facilities to select hinges that align with their architectural vision.

Application-Specific Hinge Selection

Selecting the right ball bearing hinges for specific industrial applications is crucial to ensure optimal performance and longevity. Factors to consider include door weight, frequency of use, environmental conditions, and security requirements.

For heavily trafficked areas or doors with high frequency of use, choosing hinges with higher-grade ball bearings will extend their service life and reduce the need for replacements. Additionally, assessing the door’s weight and size will determine the appropriate hinge size and load capacity.

When dealing with corrosive or harsh environments, opting for stainless steel hinges ensures resistance to rust and deterioration. For added security, hinges with non-removable pins can be employed, enhancing the door’s integrity against forced entry.

Quality Assurance and Certification

As industrial manufacturers rely on the efficiency and reliability of their equipment, sourcing hinges from reputable suppliers is essential. Trusted manufacturers often provide quality assurance through rigorous testing and certification processes. Ensuring that the hinges comply with industry standards guarantees their suitability for industrial applications.

Conclusion

In conclusion, ball bearing hinges for exterior doors are a vital component in the industrial manufacturing sector. Their exceptional load-bearing capacity, smooth operation, weather resistance, enhanced security, ease of installation and maintenance, design versatility, application-specific selection, and quality assurance make them a preferred choice for industrial facilities worldwide. Choosing the right ball bearing hinges not only ensures the seamless operation of exterior doors but also contributes to the overall efficiency, safety, and security of industrial facilities. As a leading manufacturer in the industrial sector, our commitment to producing high-quality ball bearing hinges remains unwavering, supporting our customers’ success in their diverse industrial endeavors.

You might also be interested: