Weld On Hinges Wholesale

We can customize welded hinges or have them readily available from stock. We can provide high quality products and ensure that we offer favorable prices and shipment within the stipulated lead time.

You can request any customization for welded hinges. You can put your brand logo on the product. You can provide detailed drawings and produce according to the drawings.

- Customizable

- Fast Delivery

- ODM & OEM

Weld On Hinge Specifications:

If you are a distributor, we have rich specifications for you to choose from; if you are a manufacturer, we can provide customized product service. We can customize the most suitable welding hinge for your equipment.

- Short lead time

- Rapid prototyping

- Small batch customization

Weld On Hinges applications

Gates and Fences:

Weld-on hinges are commonly used for attaching gates and fences, providing smooth and sturdy swinging movement.

Doors:

They are used in heavy-duty doors, such as industrial or garage doors, to ensure reliable pivoting and support.

Truck and Trailer Doors:

Weld-on hinges are often used on truck and trailer doors, allowing them to open and close securely.

Machinery and Equipment:

These hinges find applications in heavy machinery and equipment where a durable hinge connection is required.

Automotive:

Weld-on hinges are utilized in automotive applications, including customizations and repairs for doors and panels.

Agricultural Equipment:

They are used in various agricultural equipment, like tractor attachments and barn doors.

Marine:

In marine environments, weld-on hinges are essential for boat hatches, doors, and other marine applications.

Industrial Machinery:

Weld-on hinges are incorporated into industrial machinery to facilitate movement and access for maintenance.

Custom Fabrications:

They are frequently used in custom metal fabrications for unique projects that require hinge functionality.

Structural Applications:

In structural engineering, these hinges can be employed for specific pivot points in bridges, cranes, and other large structures.

Weld on Hinges of Common Specifications

Commonly used welded hinges are fully stocked with no MOQ requirements. If we don’t have the specifications you need, you can contact us for a custom order.

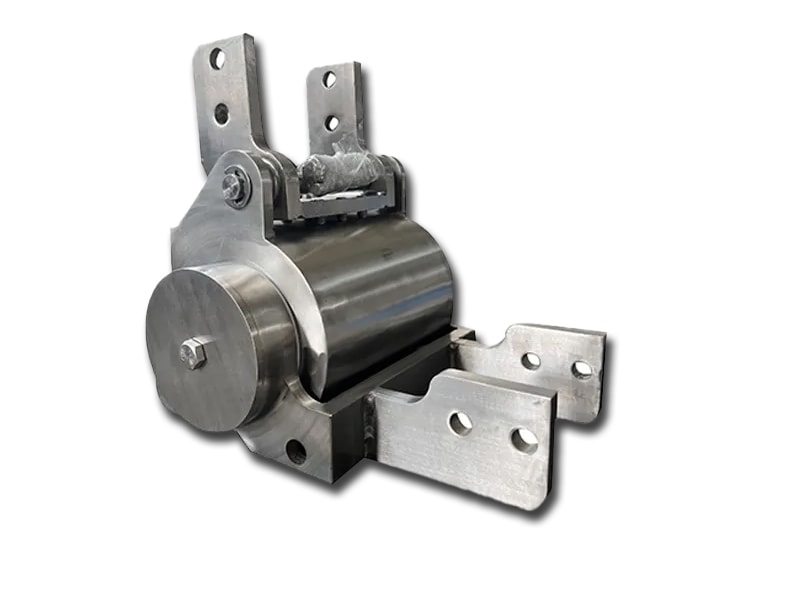

Heavy duty weld on hinges with built-in balancer

We customize the most common industrial welded hinges as well as the most complex heavy duty welded hinges with special features.

This is a customized weld on hinge professionally used for lid mounting on reactors with a built-in balancer. You can easily open and close the heavy lid.

Accept small batch customization

We don’t require high quantities for customization and accept small quantities. The purpose is to meet the needs of DIY users.

Real Reviews from Real Customers

Here are some of the comments our customers made about our products.

FAQ

We know you might have more questions, so here’s a list of the questions we get asked the most about weld on hinges.

What are weld on hinges, and how do they work?

Weld on hinges are mechanical joints that allow two parts to pivot relative to each other. They consist of two plates, one with a pin and the other with a barrel, which are joined by welding. When the pin rotates within the barrel, it enables the two connected parts to move.

What materials are commonly used for weld on hinges?

Weld on hinges are typically made from various materials, including steel, stainless steel, brass, and aluminum. The choice of material depends on factors such as load capacity, environmental conditions, and aesthetic preferences.

What are the key factors to consider when selecting a weld on hinge?

When choosing a welded hinge, consider factors like load capacity, hinge size, material compatibility with your application, corrosion resistance, and the type of movement required (e.g., butt hinges for swinging doors or piano hinges for continuous support).

How do I determine the appropriate size and load capacity for my weld on hinge?

To determine the right size and load capacity, calculate the weight or force your hinge needs to support and ensure the hinge’s specifications, such as size and load rating, exceed these requirements. It’s also important to consider the angle of rotation and the number of hinges needed for even load distribution.

Are there different types of weld on hinges available, and what are their applications?

Yes, there are various types of welded hinges, including butt hinges, continuous (piano) hinges, and strap hinges, each designed for specific applications. Butt hinges are commonly used for doors and cabinets, continuous hinges for lids and panels, and strap hinges for gates and heavy doors.

How should I maintain and care for weld on hinges to ensure their longevity?

To maintain welded hinges, periodically lubricate them with a suitable lubricant to prevent corrosion and ensure smooth movement. Check for signs of wear and replace hinges if they become damaged or loose. Regular maintenance will extend the life of your hinges and ensure their functionality.

- No.10, Juyuan II Road, Shangtun, Liao Bu Town, Dongguan City, Guangdong Province, China

- +86 136 5038 7336

- [email protected]

Send us a message

Send us a message if you have any questions or request a quote.