Navigating through the realm of hinges, it’s fascinating to observe how specific components, like the piano hinge, have found their way into various applications. Though the name might imply a singular use, these hinges play an integral role beyond the realm of music. So, what makes them so sought after in the industrial manufacturing sector?

Piano hinges, also known as continuous hinges, come in various types tailored for the industrial manufacturing sector. These include heavy-duty piano hinges, corrosion-resistant variants, weld-on versions, and customized ones based on specific lengths, materials, or finishes. Additionally, there are pre-drilled and undrilled options, differing in installation flexibility.

Delving deeper, it’s pivotal to comprehend the types and the distinctions within the spectrum of piano hinges, especially when their usage expands into multifaceted industrial manufacturing scenarios.

What are Continuous Hinges?

Piano hinges, often dubbed continuous hinges, stretch over the entire length of two adjoining surfaces. They excel in guaranteeing alignment, reducing any potential warping.

Their broad expanse ensures the load is evenly spread, curbing chances of hinge failure. For industrial machinery doors or heavy-duty toolboxes in factories, these hinges promise durability and reliability.

Are Heavy-Duty Piano Hinges the Industry Standard?

Heavy-duty variants are reinforced to endure more strain and wear. As their name implies, these are stalwarts in environments necessitating resilience, especially in the context of equipment exposed to high levels of stress.

The gauge of the material, usually steel or stainless steel, is thicker, allowing them to support heftier weights without compromising their efficiency or structural integrity.

Can Corrosion-Resistant Piano Hinges Enhance Durability?

For environments susceptible to rust or chemical exposure, corrosion-resistant piano hinges become essential. They’re crafted using materials like stainless steel or coated with anti-corrosive layers.

Such attributes enhance their lifespan, ensuring that industrial equipment remains in optimal working condition, without hinge degradation being a cause for concern.

Are Weld-On Piano Hinges a Secure Choice?

Weld-on versions, as the term suggests, are designed for applications where they’re welded onto surfaces. This method assures an exceptionally secure attachment, making them indispensable in scenarios demanding unwavering hinge stability.

For large machinery or industrial setups requiring reinforced joints, these hinges tick all the boxes of reliability.

Why Opt for Customized Piano Hinges?

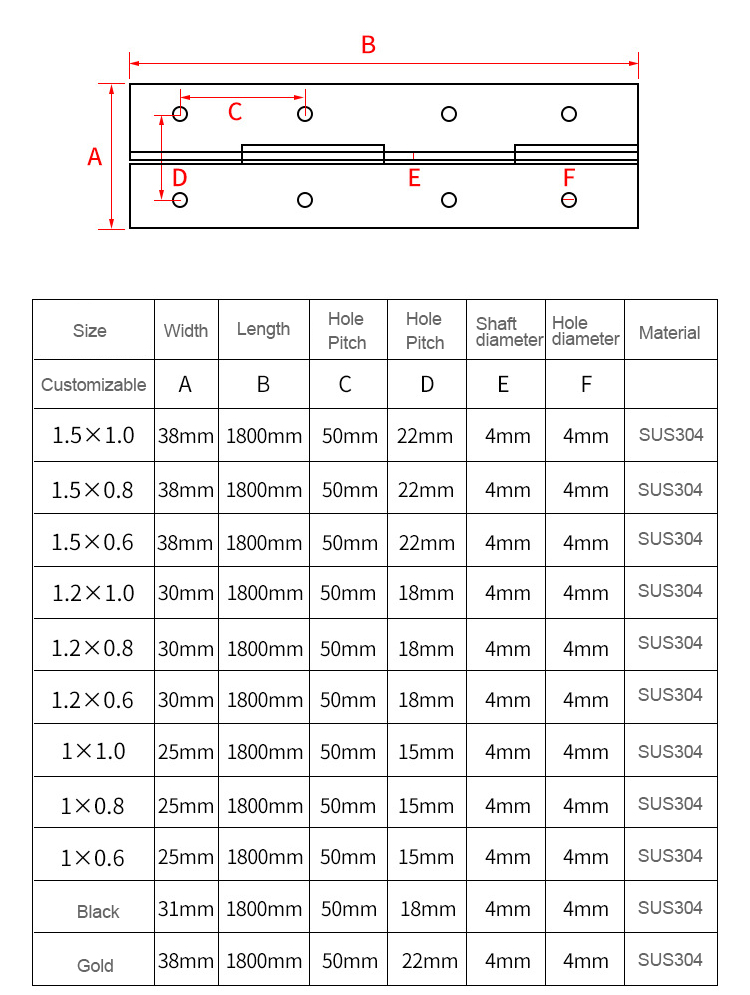

In the industrial manufacturing domain, customization is king. Piano hinges can be tailored to match specific lengths, widths, or finishes.

This adaptability facilitates manufacturers in ensuring their equipment is not only functional but also aligns with specific design or branding prerequisites. It’s not just about aesthetics but about precise functionality tailored to exact needs.

Are Pre-Drilled and Undrilled Hinges Functionally Different?

Pre-drilled piano hinges come with pre-set holes, ensuring ease of installation. They’re often the choice for projects requiring rapid assembly.

In contrast, undrilled hinges offer manufacturers the flexibility to determine hole placements, catering to unique attachment requirements in specialized industrial applications.

Do Material Choices Impact Hinge Performance?

Material selection is paramount, given the varied environments these hinges operate in. From aluminum, steel, to stainless steel, the material’s choice impacts weight support, corrosion resistance, and overall durability.

While aluminum offers lightweight strength, stainless steel champions in corrosion resistance, a crucial factor in many industrial settings.

How Do Piano Hinge Finishes Influence Their Application?

A hinge’s finish can be more than cosmetic. From polished, plated to galvanized, the finish can influence a hinge’s resistance to elements and its appearance.

Galvanized finishes, for instance, bolster resistance against rust, making them an ideal pick for machinery prone to moisture exposure.

Conclusion

Piano hinges, far from their musical association, have firmly anchored themselves within the industrial manufacturing sector. Their diversity in type and adaptability ensures they’re not just versatile but pivotal in ensuring machinery and equipment’s optimal performance. Recognizing their types and nuances is essential for informed decision-making in industrial applications.

You might also be interested: