Piano hinges are a special class of industrial hinges. It is called a piano hinge because it was first used on piano lids. It has another name that is called a continuous hinge.

If you are a factory buyer and need to purchase or order a piano hinge, then this article may be helpful to you. I will discuss the following 9 areas Discuss how to choose the right piano hinge.

Hinge Materials

The material used to produce a piano hinge will have a direct impact on its various performance indicators. The most direct impact is its load-bearing performance. The three most common materials used in the production of piano hinges on the market today are aluminum, iron, and stainless steel.

Aluminum piano hinges are very light, the same size and size as piano hinges, weigh lighter than iron or stainless steel material piano hinges, and the material cost is also less. Aluminum piano hinges have good corrosion resistance, which makes them fine for use even in wet environments.

Iron piano hinges generally require surface treatment to protect the iron material from corrosion. This is because iron is more likely to corrode or rust than other materials, whether in a dry or wet environment. We have a special discussion about industrial hinges rusting: What to do when industrial hinges are rusty

Piano hinges made of stainless steel are the best performers. They are better than aluminum and iron hinges in terms of load-bearing performance and corrosion resistance. And this material does not require maintenance or even surface treatment. The material itself has good corrosion resistance.

Hinge length

An important feature of piano hinges is that their length is much greater than their expanded width. So the first thing we need to determine when choosing piano hinges is the length of the hinge.

The choice of hinge length needs to be determined by the length of the door. The length of the hinge cannot exceed the length of the door, so the length of the hinge can be as long as the length of the door or slightly shorter than the length of the door.

However, there is a limit to the length and width of the hinge, and it is not possible to extend the length of the hinge indefinitely. If it is a very long door, then we may not be able to use one piano hinge, but rather install it in several pieces. If a piano hinge is too long, it is inconvenient for transportation and the hinge tends to bend and deform. This length needs to be determined by an experienced engineer.

Material Thickness

The thickness of the piano hinge is also a key factor to be considered. The length, the width of the hinge, and the thickness of the material need to be coordinated. Each dimension is too large or too small. Each of these dimensions is too large or too small to be reasonable.

The thickness of the material ranges from 1mm to 4mm, which is a relatively common thickness range. In most cases, this thickness range can meet our needs. requirements. As for special thicknesses, such as super thin or super thick, special customization is required.

The thickness of the hinge is also an important factor affecting the cost, depending on the thickness of the material, the price often varies greatly, so if you consider the cost , it is necessary to choose the lowest cost thickness within the appropriate range.

Spread Width

Spread width means the distance between the edges of two hinge blocks when they are unfolded and placed flat on a horizontal plane. The spread width relates to the location and size of the space in which we install them. If the installation location is too narrow, then attention needs to be paid to whether the hinge spread width is appropriate for the installation.

We have already discussed the need to coordinate the three dimensions of hinge length, spread width, and material thickness. Therefore, the width of the piano hinge also needs to be considered The thickness and length of the hinge should also be taken into account.

For questions about dimensions, you can consult our engineers directly or leave me a message on the contact page of our website.

Rotation angle

The angle of rotation is a factor that must be considered. This directly determines the opening angle of our doors. For piano hinges, the maximum opening angle can generally reach 270 degrees. This opening angle is also suitable for most of our use scenarios.

If you require the hinge to rotate less than 270 degrees or to stop at a predetermined angle, it will require special customization.

Diameter of the pin

The diameter of the pin is always the most important component of a hinge product. It will directly determine the load-bearing size and life of the hinge, and piano hinges are no exception. The piano hinge’s pin is a long, round metal bar. When connecting two hinge blocks, the pin is passed through from one end until the pin is fully driven into the hinge block.

When we check the pin, we must choose the right pin diameter. Also, look to see if the pin is securely installed. Some hinge pins are welded directly to the hinge block, and some are installed through the interference fit of the shaft and the hole.

Installation method

There are two types of hinge installation, one is pre-drilled and the other is welded. The choice is based on our actual needs.

If the installation is an open hole, you need to know the size of the open hole, and the number of open holes. And if it is welded installation, you need to pay attention to the material problem, iron material welding After the welding of iron materials to re-coat a layer of protective paint, because the location after welding, the surface of the protective layer has been destroyed. And if it is made of stainless steel, it is not necessary, only To polish smoothly, the weld slag can be processed clean. Aluminum materials generally can not be welded installation.

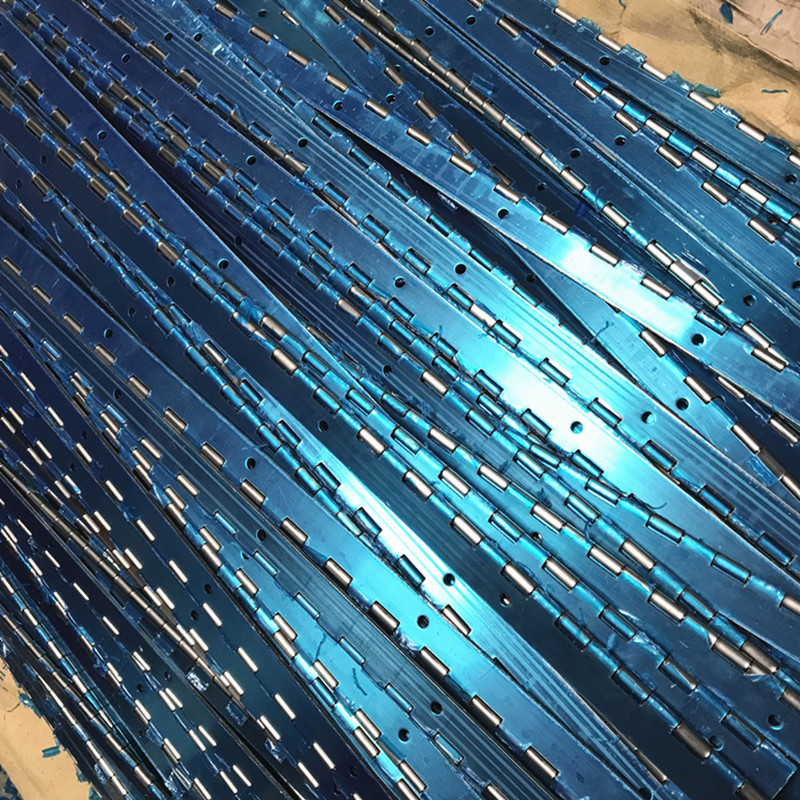

Surface Finishes

Aluminum materials can have a variety of surface finishes, and even a variety of colors can be chosen. Iron materials are generally plated, electrophoresis, and spray paint. Stainless steel material Generally uses the polished way. Or if you do not consider its aesthetics, you can not do any surface treatment. The choice can be determined according to the actual situation.

Knuckle length

The knuckle length is the length of the hinge hole where the two hinge blocks fit into each other, as shown in the figure below. This factor is not usually considered too much, as the engineer will determine this size beforehand. Of course, if you are ordering a custom piano hinge, you can request this size.

These are some of the factors that you need to take into account when choosing a piano hinge, and if you need to order a piano hinge, you can contact us now. us. Make a request based on these factors above and IHINGES will get back to you right away.