Navigating the universe of industrial components, we often find ourselves confronted with intricate details that demand attention. Among these, spring loaded piano hinges have a story worth dissecting. But what makes these hinges stand out in the realm of industrial manufacturing?

Spring loaded piano hinges are engineered to return to a predetermined position once force is removed. This innate trait ensures optimal functionality in equipment and machinery, offering a blend of movement precision and stability.

Beyond their basic mechanism, understanding the nuance and breadth of their applications becomes crucial. The more we know, the better equipped we are to harness their full potential.

How Does Spring Loading Enhance Hinge Functionality?

The addition of springs to piano hinges bestows them with self-closing or self-returning capabilities. This is especially crucial in applications where manual return is not feasible or efficient.

In the expansive world of industrial manufacturing, mechanisms that can self-regulate or self-correct, like these hinges, become invaluable. They ensure processes remain smooth, consistent, and less prone to human error.

Why Opt for Heavy-Duty Spring Loaded Hinges?

Not all environments are the same. Heavy-duty spring loaded hinges are tailored for scenarios demanding resilience. They are typically reinforced, catering to applications with higher stress or weight requirements.

Being designed with thicker gauge materials, they not only promise sturdiness but also longevity, guaranteeing optimal performance even under intensive industrial usage.

What Role Does Corrosion Resistance Play?

In hostile environments, susceptible to moisture or chemicals, spring loaded hinges need an added layer of protection. Enter corrosion-resistant variants.

Crafted using materials like stainless steel or given special finishes, these hinges ward off degradation and rust. Such attributes not only ensure longevity but also consistent functionality, crucial for process-intensive industries.

How Customizable are These Hinges?

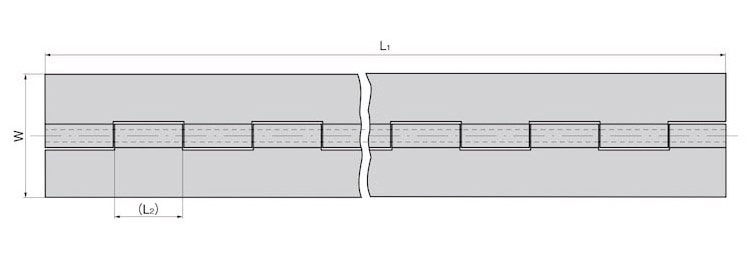

One size doesn’t fit all, especially in industrial manufacturing. Spring loaded piano hinges can be tailored – be it in terms of length, width, or even spring tension.

Such adaptability allows manufacturers to meet specific equipment requirements, ensuring not just fit but also optimized operation.

Are Pre-Drilled Variants Advantageous?

Speed often becomes paramount in industrial setups. Pre-drilled spring loaded piano hinges offer the advantage of quicker installation thanks to their preset holes.

While they streamline assembly, they also reduce room for error, becoming the go-to choice for manufacturers keen on swift and precise installations.

How Do Different Materials Impact Performance?

Material choice is pivotal. From aluminum, brass to stainless steel, the selected material impacts factors like weight, strength, and corrosion resistance.

Stainless steel, for instance, provides an excellent balance between strength and resistance to elements. Tailoring material choices based on application specifics can drastically enhance hinge performance.

How Significant is the Role of Finish?

While often perceived as mere aesthetics, the finish of a spring loaded piano hinge can be functional. Options range from polished, brushed, to even coated finishes.

Certain finishes, such as galvanized, augment resistance against external elements, making them ideal for applications exposed to hostile conditions.

Conclusion

Spring loaded piano hinges, with their versatility and precision, cement themselves as indispensable in the industrial manufacturing landscape. Recognizing their variants, features, and nuances is key to leveraging their full potential. As we delve deeper into the industrial age, such components remind us of the blend of engineering and innovation at play.

You might also be interested: