Salt Spray Test Chambers are critical tools for evaluating the corrosion resistance of materials and coatings. The Salt Spray Test Chamber Hinges used in these chambers play a vital role in maintaining the integrity and functionality of the equipment. In this blog post, we will delve into the unique characteristics and requirements of hinges designed specifically for Salt Spray Test Chambers. From their corrosion-resistant properties to their design considerations, we will explore five key aspects that highlight the significance of these specialized hinges. These hinges are very different in structure and function from heavy duty bullet hinges.

Corrosion-Resistant Materials and Coatings

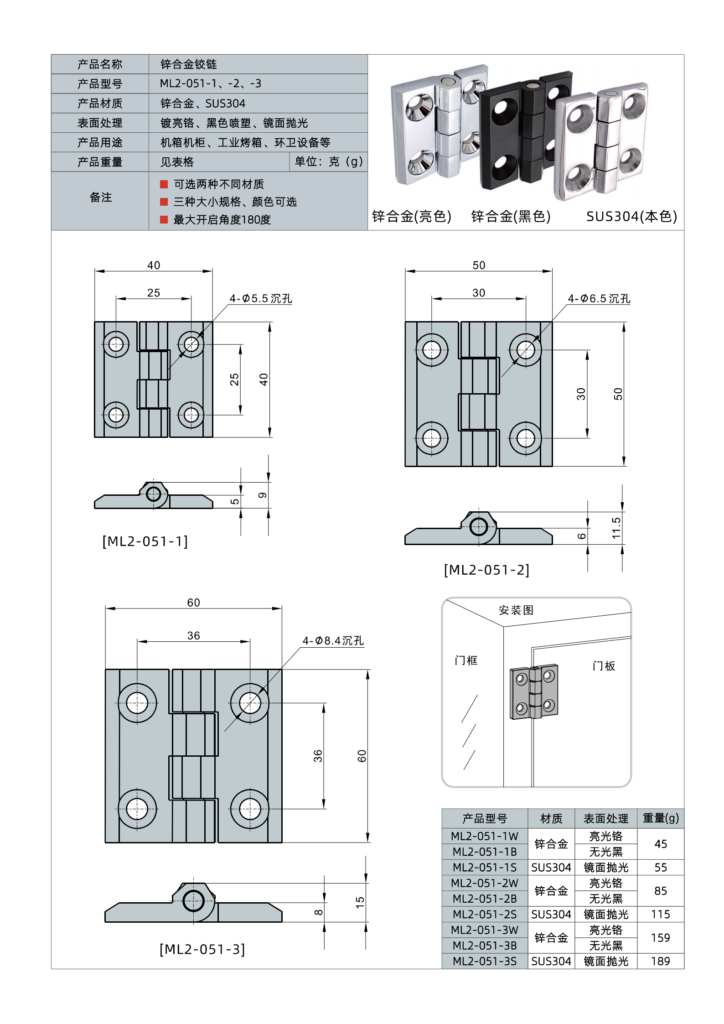

Salt Spray Test Chambers are exposed to highly corrosive environments, making it crucial to have hinges that can withstand the corrosive effects of salt spray. These specialized hinges are constructed using corrosion-resistant materials such as stainless steel or alloys with high resistance to oxidation and corrosion. Additionally, they are often coated with protective layers, such as electroplated zinc or corrosion-resistant paints, further enhancing their durability and resistance to salt spray. The combination of corrosion-resistant materials and coatings ensures that the hinges can withstand prolonged exposure to salt spray without compromising their functionality.

Furthermore, these hinges undergo rigorous testing and validation procedures to ensure their effectiveness in corrosive environments. They are subjected to simulated salt spray tests to evaluate their resistance to corrosion, enabling manufacturers to provide reliable and long-lasting hinges specifically designed for Salt Spray Test Chambers.

Sealed Design for Protection Against Moisture

Salt Spray Test Chambers operate in environments with high humidity and moisture levels. To prevent moisture ingress and subsequent corrosion, the hinges used in these chambers feature a sealed design. The hinges are equipped with rubber or silicone gaskets and seals that create a barrier against moisture, preventing it from reaching the internal components of the hinges. This sealed design not only enhances the corrosion resistance of the hinges but also contributes to the overall longevity and performance of the Salt Spray Test Chamber itself.

Additionally, the sealed design of these hinges minimizes the risk of leakage or cross-contamination during testing, ensuring accurate and reliable results. The tight seal provided by the hinges maintains the integrity of the test chamber, allowing for precise control of salt spray conditions and effective evaluation of material durability under corrosive environments.

Robust Construction for Heavy-Duty Applications

Salt Spray Test Chambers often require frequent opening and closing for sample placement and retrieval. Therefore, the hinges used in these chambers must be designed to withstand repetitive and heavy-duty usage. These specialized hinges feature robust construction, incorporating sturdy components such as thick gauge metals, reinforced pins, and heavy-duty bearings.

The robust construction of these hinges ensures their ability to withstand the continuous stress and strain encountered during the operation of Salt Spray Test Chambers. They can handle the weight of the chamber doors without sagging or deforming over time, ensuring smooth and reliable operation throughout the testing process. Additionally, the heavy-duty design minimizes the risk of premature wear or failure, providing a long service life for the hinges and contributing to the overall durability of the test chamber.

Adjustable Tension and Positioning

Salt Spray Test Chamber hinges often require precise tension adjustment and positioning to maintain the desired opening. And closing force and ensuring proper alignment of the chamber doors. These hinges are equipped with adjustable tension mechanisms. Allowing operators to fine-tune the resistance provided by the hinges according to specific requirements. This feature is particularly important for achieving consistent and repeatable results during testing.

Moreover, the hinges offer adjustable positioning options. Enabling precise alignment of the chamber doors to ensure a tight seal. Proper alignment is crucial to prevent salt spray leakage and to maintain the desired testing conditions within the chamber. The ability to adjust tension and positioning adds versatility to these hinges. Accommodating various sample sizes and configurations, and enhancing the overall flexibility and usability of Salt Spray Test Chambers.

Maintenance and Lubrication

To ensure the long-term performance and reliability of Salt Spray Test Chamber hinges, proper maintenance and lubrication are essential. These hinges are designed for easy maintenance, with accessible lubrication points and provisions for periodic lubrication. Lubricants are specifically formulated for corrosive environments. Such as synthetic oils or greases with anti-corrosion additives, are used to minimize friction and prevent corrosion-related issues.

Regular lubrication of the hinges helps reduce wear, noise, and the potential for corrosion. It also ensures smooth operation and extends the service life of the hinges. Manufacturers provide guidelines and recommendations for lubrication intervals and suitable lubricants. Enabling operators to maintain the hinges effectively and maximize their performance in Salt Spray Test Chambers.

Corrosion-resistant hinges specifically designed for Salt Spray Test Chambers are crucial components that enable the reliable. And long-term operation of these testing devices. By selecting hinges with superior corrosion resistance, and robust design. And the appropriate load-bearing capacity. You can ensure the durability and integrity of your testing equipment in harsh salt spray environments. Regular maintenance and adherence to international standards further contribute to the optimal performance of these hinges. Providing accurate and reliable corrosion test results.