Description

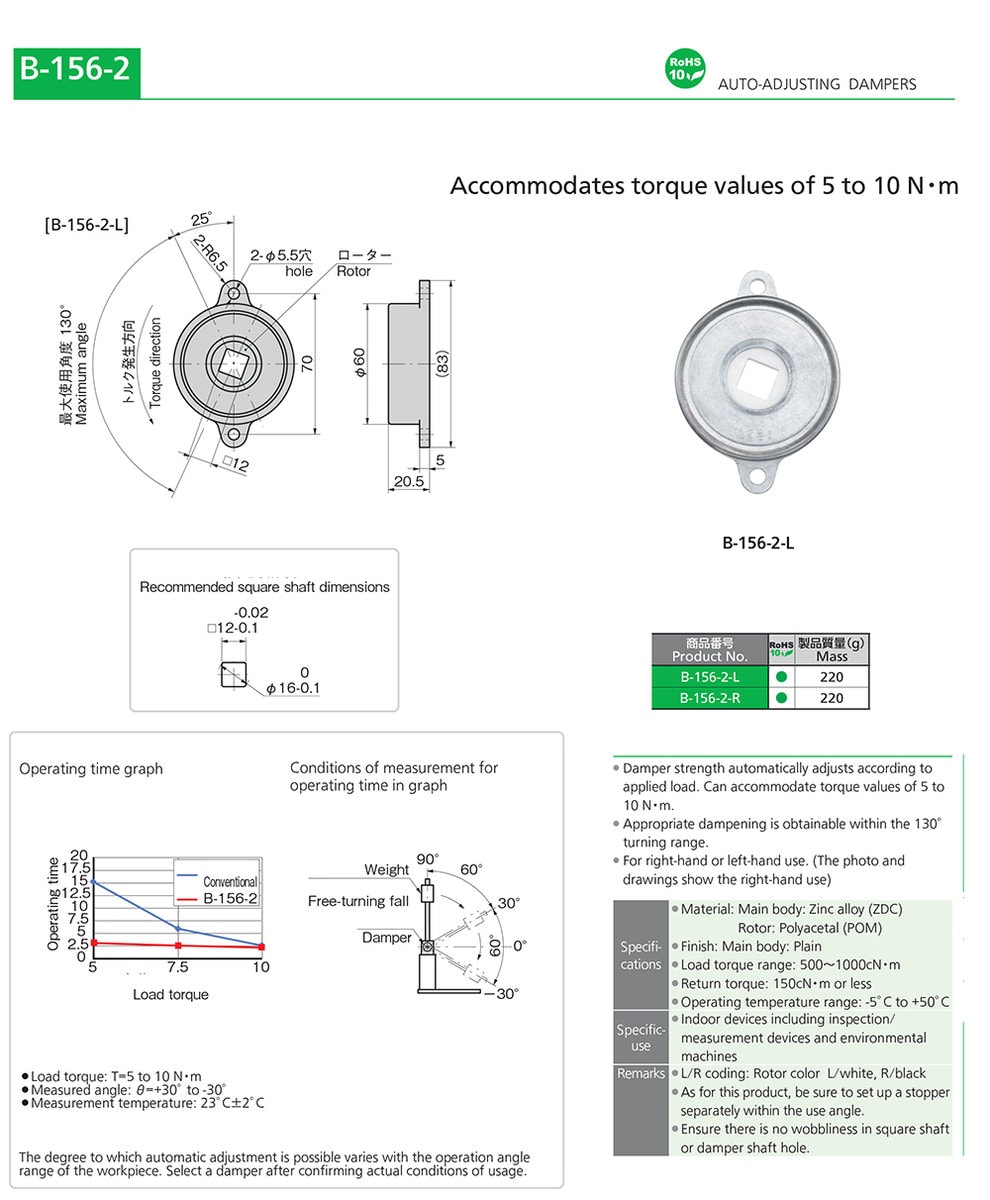

Our Auto-Adjusting Dampers are designed to provide efficient and precise control over damping in various industrial applications. These dampers feature automatic adjustment of the damper strength based on the applied load, accommodating torque values ranging from 5 to 10 N·m. With a turning range of 130°, they allow for appropriate dampening throughout their operation. The dampers are suitable for both right-hand and left-hand use, providing versatility in installation. Made from high-quality materials such as zinc alloy (ZDC) for the main body and polyacetal (POM) for the rotor, these dampers offer reliable performance and durability. They are ideal for indoor devices, including inspection/measurement devices and environmental machines.

Features

- Auto-adjustment of damper strength based on the applied load for efficient control.

- 130° turning range allows for appropriate dampening throughout the operation.

- Suitable for both right-hand and left-hand use, providing installation versatility.

- Made from high-quality materials, including zinc alloy (ZDC) for the main body and polyacetal (POM) for the rotor.

- Designed for indoor devices, including inspection/measurement devices and environmental machines.

Specific Use

These auto-adjusting dampers are specifically designed for use in indoor devices, including inspection/measurement devices and environmental machines. Their precise control over damping and reliable performance make them ideal for achieving optimal functionality in these industrial applications.

What are the Auto-Adjusting Dampers

Auto-adjusting dampers, also known as self-adjusting dampers or automatic dampers, are devices used in various mechanical systems to control and regulate the flow of air, gas, or fluid. These dampers are designed to automatically adjust their position or resistance based on changing environmental conditions or system requirements.

Auto-adjusting dampers are equipped with sensors or actuators that detect changes in temperature, pressure, or other relevant factors. Based on these inputs, the dampers can modify their position, aperture size, or damping characteristics to optimize the performance of the system.

These dampers find applications in HVAC (Heating, Ventilation, and Air Conditioning) systems, exhaust systems, engine intakes, and other industrial processes where precise control of airflow or fluid flow is crucial. By automatically adapting to changing conditions, auto-adjusting dampers enhance energy efficiency, improve system stability, and ensure optimal performance without the need for manual intervention.

FAQs

1. Q: How do these auto-adjusting dampers work?

A: The damper strength automatically adjusts based on the applied load, allowing for efficient control over damping.

2. Q: What is the turning range of these dampers?

A: These dampers have a turning range of 130°, ensuring appropriate dampening throughout their operation.

3. Q: Can these dampers be used for both right-hand and left-hand applications?

A: Yes, these dampers are suitable for both right-hand and left-hand use, providing versatility in installation.

4. Q: What materials are used for these dampers?

A: The main body of the dampers is made from zinc alloy (ZDC), while the rotor is constructed from polyacetal (POM), ensuring durability and reliable performance.

5. Q: What are the specific applications for these dampers?

A: These dampers are designed for indoor devices, including inspection/measurement devices and environmental machines, providing precise control over damping in these industrial settings.