Description

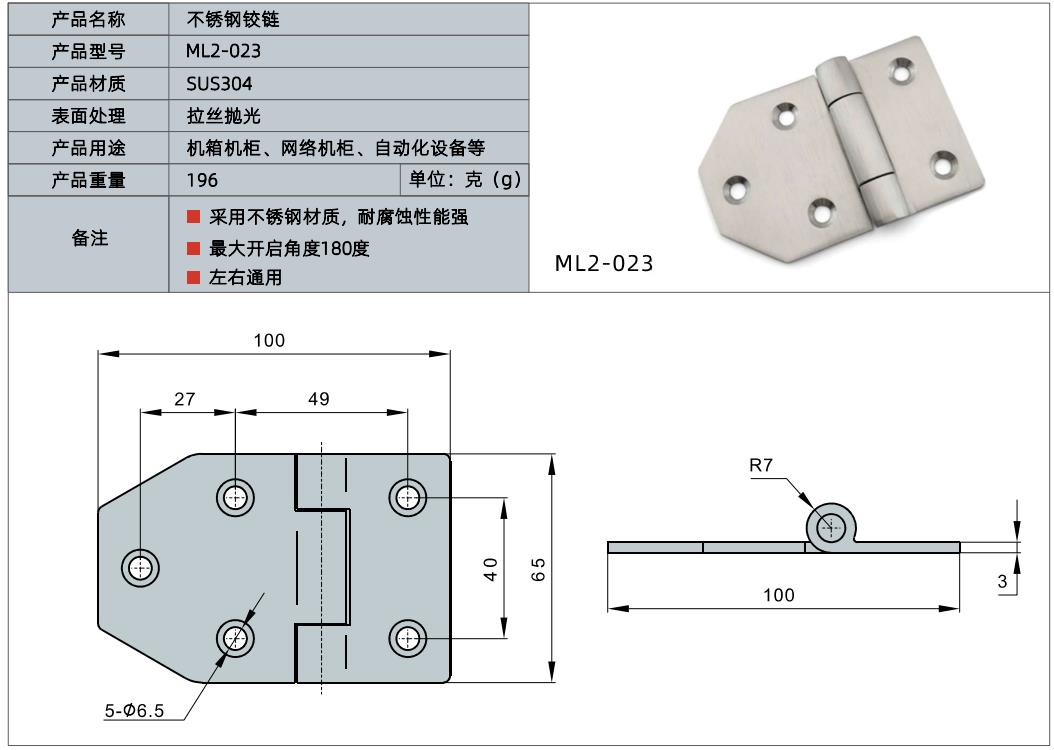

Butt hinges for automation equipment are a type of hinge that is designed for use in automated systems, such as conveyor belts or assembly lines. These hinges are specifically engineered to withstand the stresses and strains of repeated use in industrial settings.

Butt hinges for automation equipment are typically made from durable materials such as stainless steel, aluminum, or hardened steel. They are designed to provide a secure attachment point for moving parts, such as robotic arms or conveyors, while allowing for smooth and easy movement.

Features:

Features of butt hinges for automation equipment include their ability to withstand repeated use and exposure to harsh conditions such as extreme temperatures, humidity, and chemicals. They are often designed with a sealed bearing mechanism to prevent dirt and debris from interfering with the hinge’s function. Some models may also feature an adjustable tension system to ensure that the hinge moves smoothly and securely. Additionally, butt hinges for automation equipment are available in a variety of sizes and styles to fit the specific needs of different systems and applications.

FAQs:

What are the benefits of using hinges for automation equipment?

Butt hinges for automation equipment are specifically designed to withstand the stresses and strains of repeated use in industrial settings. They are durable and often feature a sealed bearing mechanism to prevent dirt and debris from interfering with the hinge’s function. Some models may also feature an adjustable tension system to ensure that the hinge moves smoothly and securely.

What materials are butt hinges for automation equipment typically made from?

Butt hinges are typically made from durable materials such as stainless steel, aluminum, or hardened steel. These materials are chosen for their ability to withstand repeated use and exposure to harsh conditions such as extreme temperatures, humidity, and chemicals.

How do you choose the right butt hinge for automation equipment?

Choosing the right butt hinge involves considering factors such as the weight and size of the moving parts, the environment in which the system will operate. And the specific needs of the application. It is important to select a hinge that is strong enough to support the weight of the moving parts. While also allowing for smooth and easy movement.

How do you install butt hinges?

To install a butt hinge, first, identify the location and number of hinges needed for the moving parts. Then, mount the hinges securely using screws or other fasteners. Ensuring that they are aligned properly and securely attached to the moving parts and the stationary parts.

What maintenance is required for butt hinges?

Regular maintenance is important for ensuring the continued smooth and reliable operation of butt hinges for automation equipment. This may include cleaning the hinges to remove dirt and debris and lubricating the hinges to reduce friction and wear. And tighten any loose screws or other fasteners to ensure that the hinges remain securely attached.