Piano hinges offer continuous support and durability, making them ideal for industrial and specialized applications.

When ordering piano hinges, ensure you share precise dimensions, material specifications, and installation needs with your manufacturer to guarantee a flawless fit. Custom specifications like hinge length, width, and pre-drilled options all contribute to hinge performance and longevity.

Understanding these key details is crucial to securing a high-quality hinge for your needs.

What Are Piano Hinges?

Piano hinges, also called continuous hinges, are long, uninterrupted hinges designed to evenly support weight across their entire length. Unlike standard hinges, which secure objects at two or three points, piano hinges offer continuous support, adding stability and strength to heavier objects. Typically made from materials like stainless steel, brass, and aluminum hinges, they offer a balance of strength and corrosion resistance.

Piano hinges work by distributing weight along a continuous line, making them ideal for applications that need extra stability. Their durability and even weight distribution are essential for industrial uses where reliability is paramount.

Why Choose Piano Hinges?

Piano hinges offer advantages over regular butt hinges, such as smoother operation, enhanced weight distribution, and longevity. Unlike butt hinges, which can develop stress points over time, piano hinges provide stable, long-lasting support.

Common Applications of Piano Hinges

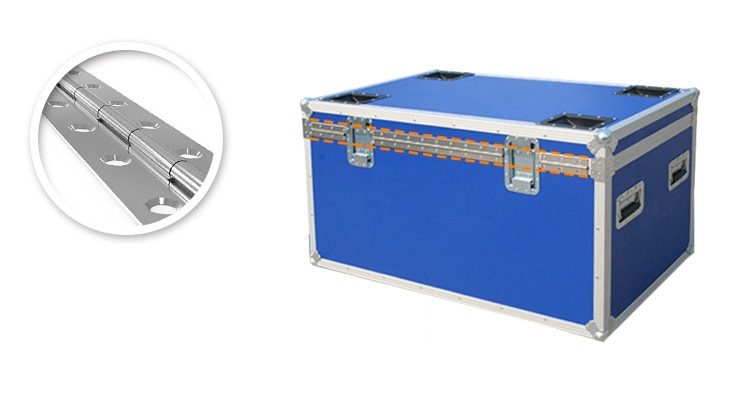

Piano hinges are widely used in both industrial and specialized applications. For example, they are a common choice in machinery doors, enclosures, and industrial storage containers due to their stability. In these environments, hinges need to withstand frequent use and heavy loads, which piano hinges can support better than typical butt hinges.

Due to their ability to bear heavy loads evenly, piano hinges are ideal for demanding applications. They are frequently used in marine hinges applications, where corrosion resistance and consistent support are vital for durability in harsh environments.

Other Special Applications

Piano hinges are also essential in settings that require smooth, quiet operation, like lab equipment doors and test chambers. Their even load distribution allows them to handle larger objects that require easy and secure opening, such as cold storage room hinges and climatic test chamber hinges.

Essential Details to Share with Your Manufacturer When Ordering Custom Piano Hinges

When ordering custom piano hinges, providing accurate specifications is crucial. Here are some key details to share:

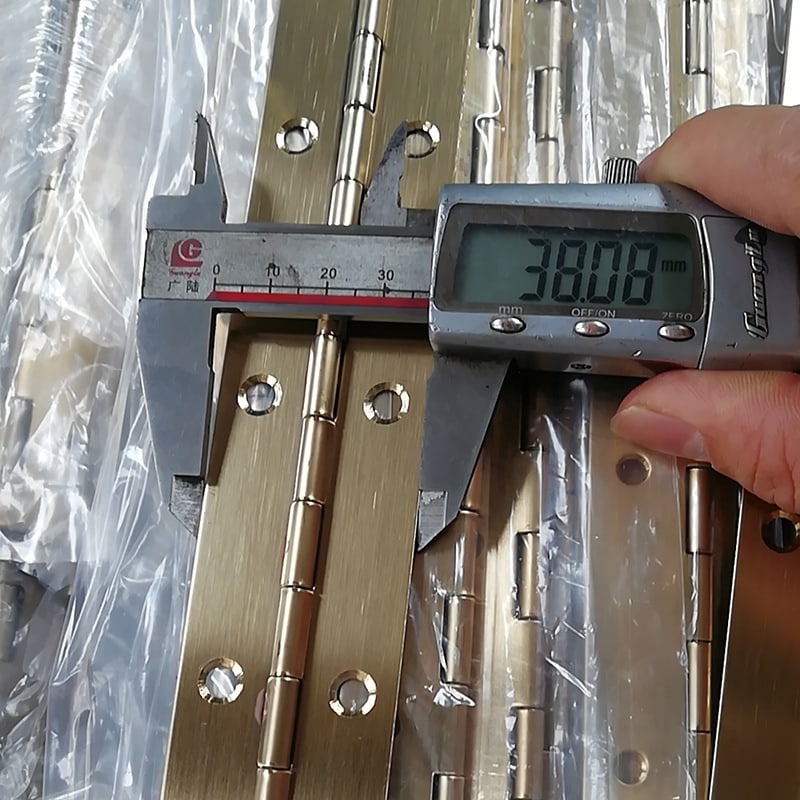

Exact Length and Width

The hinge length and opened width are fundamental for correct installation and operation. Standard piano hinges may range from a few inches to several feet. However, precise measurements are essential when hinges are manufactured for specific applications to ensure an exact fit and function.

By specifying exact measurements, you ensure the hinge aligns perfectly with your equipment. Consider the fully opened width as well as the folded length to match the design requirements.

Material Type and Thickness

Selecting the right material, such as stainless steel, brass, or aluminum, will affect the hinge’s corrosion resistance and strength. Each material type offers unique properties—aluminum for lightweight applications, stainless steel for high-corrosion environments. The thickness of the hinge material also determines its strength, so communicate specific needs to your manufacturer.

Quantity and Order Volume

Knowing the volume of hinges you need allows manufacturers to plan production more accurately and offer bulk pricing if needed. Custom orders can vary in price based on quantity, and manufacturers might have minimum order requirements, particularly for large applications like heavy-duty hinges or detachable hinges.

Installation Requirements

Discuss whether pre-drilled holes or welding options are needed, as these impact the installation process. If specific hole placements are required, sharing a diagram with the manufacturer can save time and ensure alignment. Pre-drilled or weld-on hinges options simplify installation, especially for heavy-duty applications.

Specialized Customizations

If you require unique features like a specific connection pin diameter, anti-corrosion treatments, or logo engraving, include these in your order specifications. Customizations can enhance the hinge’s appearance, durability, and performance. Some industries require particular finishes or coatings for added corrosion resistance, so communicate any special requirements upfront.

Important Packaging Considerations Based on Hinge Length and Quantity

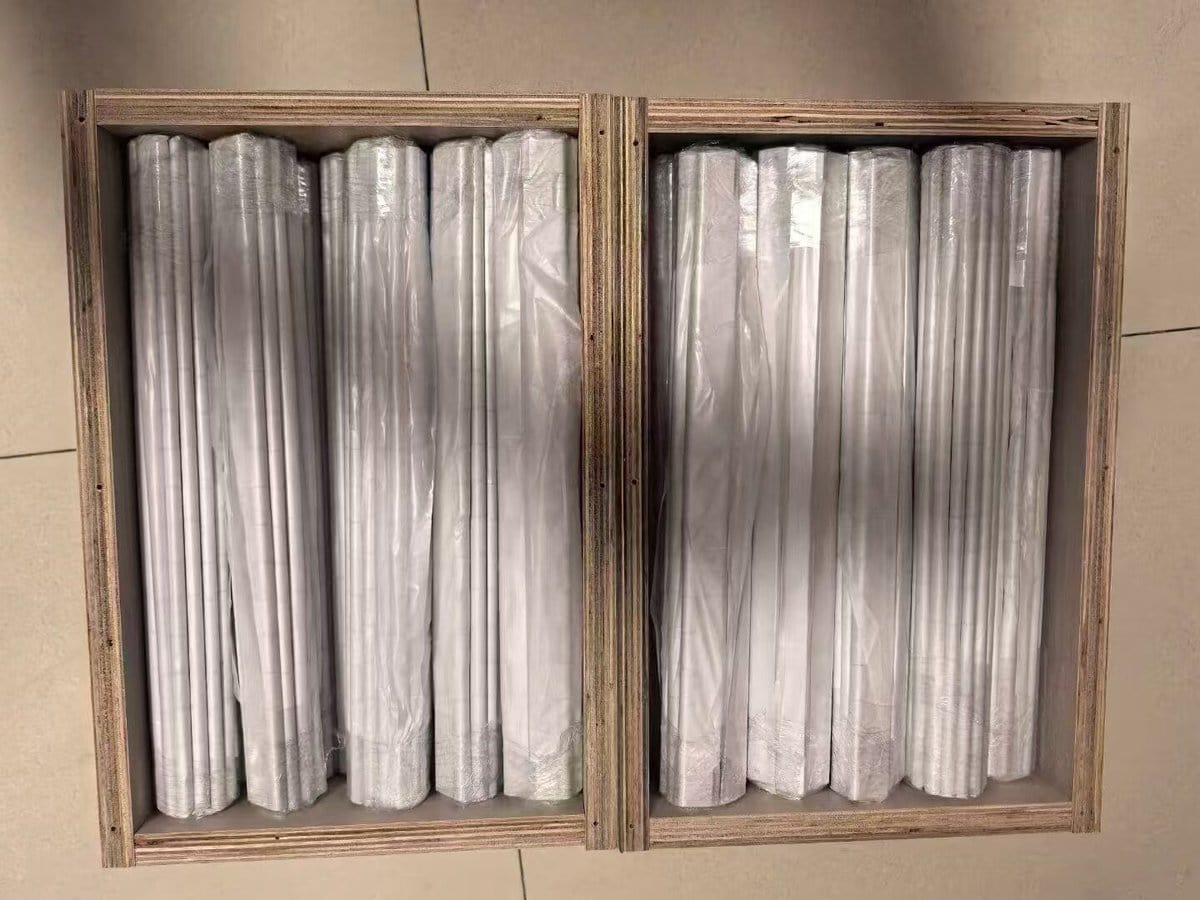

The length and quantity of piano hinges can impact packaging requirements. Since longer hinges are more prone to bending or damage, appropriate packaging materials and methods are essential.

Recommendations for Longer Hinges

Long piano hinges benefit from protective wrapping, like foam or bubble wrap, and may require special crates for added safety. Ask your manufacturer about options for secure packing to prevent bending, especially if your order includes multiple heavy-duty or custom-sized hinges.

Proper packaging reduces transit damage and ensures hinges arrive in top condition. For larger bulk orders, wooden crates may be more secure than standard boxes, especially for heavy-duty industrial orders.

Why Choose Piano Hinges Over Standard Butt Hinges?

Piano hinges provide several advantages over standard butt hinges, particularly when even load distribution and added stability are required.

Stable and Even Load Distribution

Unlike butt hinges, which have only a few mounting points, piano hinges support weight across their entire length, making them more stable and durable. For applications like heavy-duty doors or equipment enclosures, even load-bearing is essential to prevent sagging or misalignment.

Enhanced Safety and Weight-Bearing Aesthetics

Piano hinges offer a secure, balanced appearance and support heavy loads, making them a go-to choice for doors, machinery, and storage enclosures that demand reliability and safety. This stability gives them a visual advantage over smaller hinges, as they appear stronger and more capable, instilling confidence in their structural integrity.

Why Lead Times and Production Schedules Matter for Custom Orders

Lead times for custom hinges can vary based on specifications and quantity. Understanding production schedules helps you plan your order to meet project deadlines, especially if you’re placing a large or complex order.

Plan custom orders with your manufacturer to avoid delays. Confirm lead times, especially during peak manufacturing seasons or when dealing with overseas suppliers. This foresight helps prevent unexpected hold-ups that could impact your project timelines.

Questions to Ask Your Manufacturer for the Best Customization Options

To get the best possible results, ask your manufacturer about their customization capabilities and prior experience with similar projects. Understand any limitations they may have with specific materials or hinge types and ask if they offer samples or prototyping options.

Asking questions ensures your manufacturer can meet your exact needs, whether you need specialty materials or specific finishes. This is especially important for custom applications like trailer door hinges or concealed hinges where design and function are critical.

Considerations for Freight and Shipping When Ordering in Bulk

Shipping hinges in bulk requires careful planning, especially for international orders. Freight costs, shipping methods, and transit protection all impact the overall logistics.

Discuss bulk shipping options with your manufacturer to avoid unexpected fees. Ask if they offer consolidated freight or customized packaging for bulk orders to save on transportation costs and ensure safe delivery.

Conclusion

Providing detailed specifications to your manufacturer ensures your custom piano hinges meet all functional and quality standards. Whether for industrial machinery or heavy-duty enclosures, clear communication about materials, sizes, and installation needs is key to securing hinges that perform reliably for years.