Industrial doors are an essential component of any facility, from warehouses and factories to hospitals and laboratories. These doors provide a barrier between different environments, maintaining temperature control, noise reduction, and even preventing the spread of contaminants. Traditional door hinges can present several challenges in terms of reliability, durability, and maintenance, which is why magnetic hinges have emerged as a smart solution. This article will explore the science and advantages of magnetic hinges and their applications in industrial settings.

How Magnetic Hinges Work

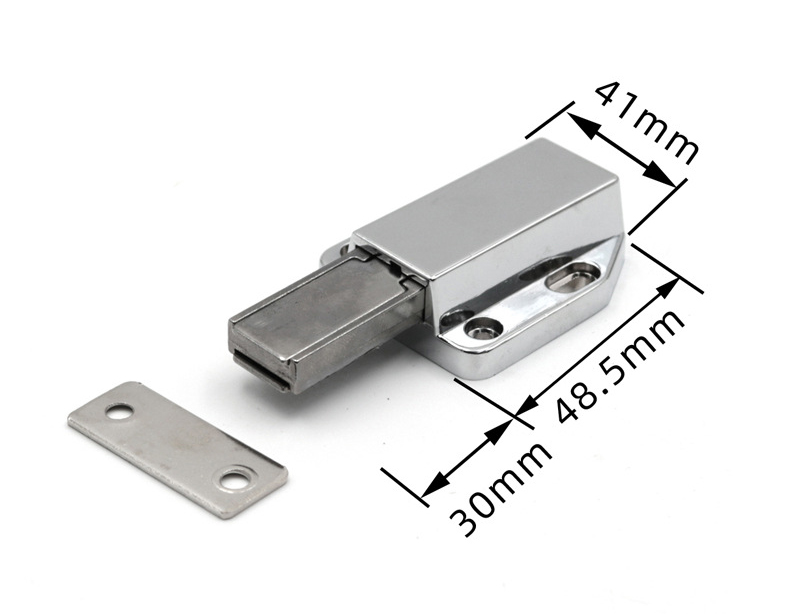

Magnetic hinges operate on the principle of attraction between opposite magnetic poles. The hinges are composed of two components, one with a north pole and the other with a south pole, which attracts each other when they come into proximity. This attraction force provides a reliable and durable hold between the door and the frame, eliminating the need for mechanical parts that can wear out over time. Magnetic hinges can also be designed to allow for controlled movement of the door, preventing slamming and reducing noise.

One of the key advantages of magnetic hinges over traditional hinges is their resistance to wear and tear. Traditional hinges rely on mechanical components, such as pins and bearings, that can corrode, loosen, or break over time, requiring frequent maintenance and replacement. In contrast, magnetic hinges have few moving parts and are composed of durable materials that can withstand harsh industrial environments.

Applications of Magnetic Hinges

Magnetic hinges are particularly suited for industrial doors that are large, heavy, and subject to high traffic. These doors can be found in various settings, such as loading docks, manufacturing plants, and commercial buildings. Magnetic hinges can also provide safety and security benefits by preventing unauthorized access, reducing the risk of injuries, and improving emergency egress. In medical and cleanroom environments, the hinges can maintain the integrity of the air filtration system, preventing the entry of contaminants and bacteria.

The Hinges vs. Traditional Hinges

Magnetic hinges offer several advantages over traditional hinges, making them a more popular choice in industrial settings. One of the primary benefits is their durability and longevity. These hinges are designed to withstand heavy usage and extreme weather conditions, making them ideal for industrial doors that are frequently used.

Installation and maintenance are also much easier with magnetic hinges compared to traditional hinges. Magnetic hinges require minimal maintenance and do not need to be lubricated or tightened over time. In contrast, traditional hinges can become loose over time, which can cause alignment issues and require frequent maintenance.

Cost-effectiveness is another major advantage of the hinges. Although they may cost more upfront, the hinges are more cost-effective in the long run due to their durability and low maintenance requirements. Traditional hinges require frequent maintenance, which can be costly over time and may need to be replaced more frequently than magnetic hinges.

The Hinges and Automation

Magnetic hinges are compatible with automatic doors, making them an excellent choice for industrial settings that require automation. The hinges can be integrated with smart technology, allowing for remote control and monitoring of industrial doors.

Customization options are also available with the hinges, allowing them to be tailored to the specific needs of the customer. This includes the ability to adjust the force of the magnet, allowing for greater control over the speed and force of the door.

The Hinges and Sustainability

In addition to their many benefits, magnetic hinges are also more environmentally friendly compared to traditional hinges. They are energy-efficient, as they do not require electricity or other energy sources to function. The hinges are also made from eco-friendly materials. Making them a sustainable choice for industrial door applications.

Furthermore, the use of the hinges can contribute to LEED certification. LEED certification is a globally recognized green building rating system that recognizes environmentally responsible building practices. The use of the hinges can contribute to points in the materials and resources category, which can help buildings achieve LEED certification.

How to Choose the Right Magnetic Hinges

Choosing the right hinges requires an understanding of the specific requirements of the industrial door. This includes factors such as the size and weight of the door, and the level of usage. And the environment in which it will be used.

Material considerations are also important when choosing the hinges. Different materials offer different levels of strength and durability. So it is important to select the appropriate material for the specific application.

Finally, it is important to consider the reputation of the manufacturer and the level of customer support they offer. Choosing a reputable manufacturer with a strong track record of customer satisfaction can ensure that the hinges will perform as expected. And that any issues can be quickly and efficiently resolved.

Conclusion

Magnetic hinges offer many advantages over traditional hinges for industrial door applications. Their durability, low maintenance requirements, and compatibility with automation make them an excellent choice for a wide range of industrial settings. Additionally, their energy efficiency and sustainability make them an environmentally responsible choice. By understanding the specific requirements of the industrial door. By selecting the appropriate materials, and choosing a reputable manufacturer, customers can ensure that they are making the right choice for their magnetic hinge solutions.