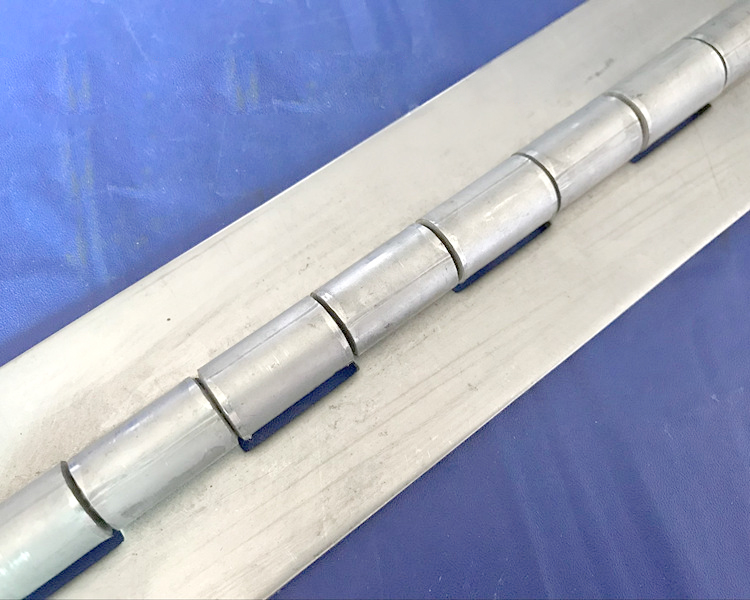

Piano hinges, also known as continuous hinges, are long, narrow hinges that run the entire length of a door or lid, allowing it to pivot smoothly. They are commonly used in a wide range of applications, from doors on musical instruments to large industrial doors. In this article, we will focus on the installation of stainless steel piano hinges, which are preferred over other materials due to their durability and resistance to corrosion. We will provide an overview of the installation process and explain why stainless steel piano hinges are a popular choice.

Why Choose Stainless Steel Piano Hinges

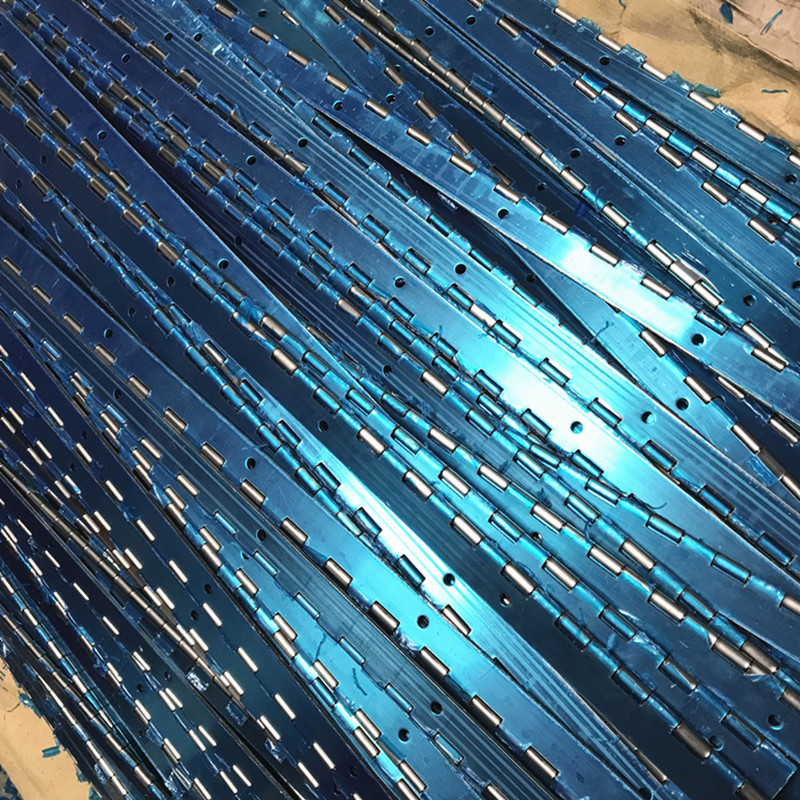

Stainless steel piano hinges are highly resistant to rust and corrosion, making them ideal for use in environments where moisture or humidity is present. They are also durable and can withstand heavy loads, making them suitable for applications that require a long-lasting hinge. When compared to other materials, such as brass or aluminum, stainless steel piano hinges are more affordable and have a longer lifespan. These advantages make them a preferred choice for industrial and commercial settings.

Tools and Materials Required

To install stainless steel piano hinges, you will need a few tools and materials, including a measuring tape and marking tool, a drill, drill bits, a chisel, a hammer, hinges, screws, and fasteners. It is important to ensure that all tools and materials are of high quality to ensure a successful installation.

Measuring and Marking

Accurate measurements are critical when installing piano hinges. To ensure that the hinges are properly aligned, it is recommended that you use a measuring tape and marking tool to mark the placement of the hinge. You should also take into consideration the weight of the door or lid and the expected load it will bear. Marking guidelines for hinge placement should be followed carefully, and door and frame preparation should be done prior to installation.

Mortising and Cutting

Cutting and mortising are essential steps in the installation process. Cutting refers to the process of creating a groove or notch in the door or frame to accommodate the hinge, while mortising involves creating a recess in the door or frame for the hinge to fit into. These steps can be done using a saw or chisel, and it is important to follow guidelines for proper cutting and mortising. Tips for cutting and mortising include using a sharp tool, making precise cuts, and ensuring that the hinge fits snugly into the groove or recess.

If it is installed on a metal door frame, then just cut the hole. Then just fix it with screws. Or use welded installation. Heavy-duty welded hinges are generally non-porous and need to be accurately measured for installation, otherwise, the position cannot be adjusted after welding.

Installation Process

Once the cutting and mortising are complete, the hinge can be attached to the door and frame using screws and fasteners. It is important to align the hinge properly to ensure that the door or lid opens and closes smoothly. The use of drill bits and screws will ensure a secure fit. Once installed, it is recommended to test the hinge for functionality.

Maintenance and Care of Stainless Steel Piano Hinges

To ensure that piano hinges continue to function properly, regular maintenance is necessary. This includes cleaning and lubricating the hinges to prevent rust and corrosion. Common issues with piano hinges include binding or squeaking, which can be addressed by identifying the issue and making necessary adjustments. Guidelines for fixing common issues should be followed carefully.

Stainless Steel Piano Hinges in Industrial Settings

Stainless steel piano hinges are commonly used in industrial settings due to their durability and resistance to corrosion. They are often used in applications. Such as heavy machinery, industrial doors, and equipment enclosures. The advantages of using hinges in the industrial field include their ability to withstand harsh environments and heavy loads. As well as their long lifespan. Real-world examples of industrial uses of piano hinges include airplane cargo doors, industrial equipment enclosures, and heavy machinery.

Conclusion

In conclusion, stainless steel piano hinges are an excellent choice for those looking for a durable and long-lasting hinge. The installation process requires attention to detail and precision, but the end result will be a smooth-operating door or lid. Regular maintenance is necessary to ensure that the hinges continue to function properly. In industrial settings, piano hinges are a popular choice due to their durability and resistance to corrosion. When installed and maintained properly, hinges are an excellent investment for both residential and industrial applications.