Industrial oven hinges are a class of industrial hinges used professionally in the industrial oven sector. These hinges are generally more load-bearing and often have some special requirements. Industrial oven hinges are a very critical component in the process of use. If a hinge accident occurs, it is usually a severe consequence.

Because the doors of industrial oven hinges are generally heavy, if the hinges break or the doors do not close tightly due to hinge deformation, the cabinet may have a serious accident during operation.

What is an industrial oven?

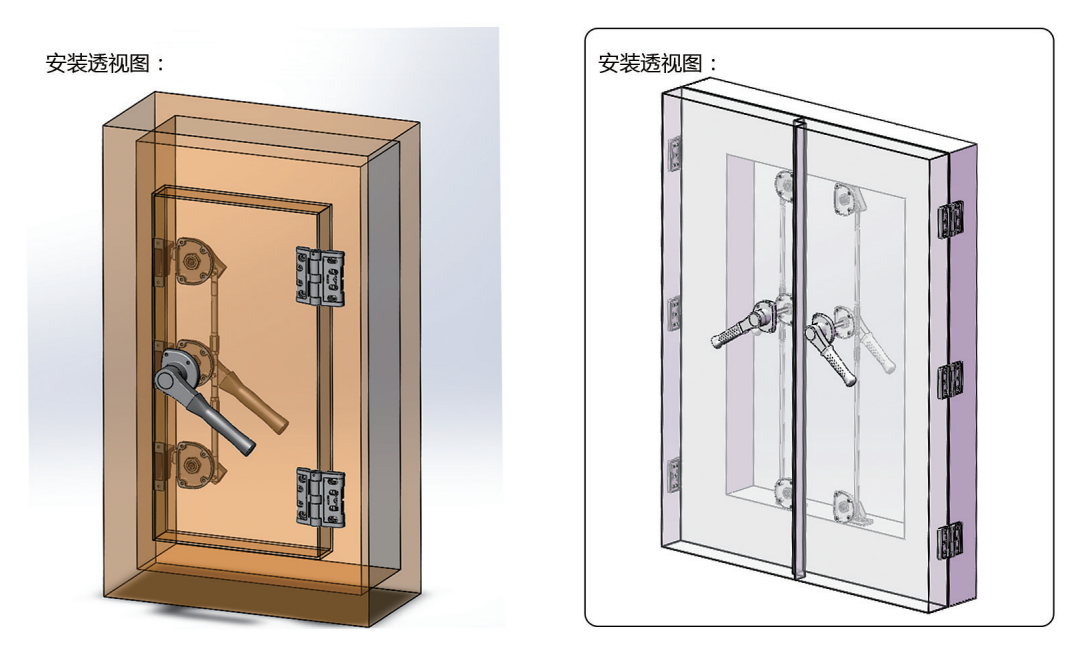

An industrial oven is a type of industrial equipment that is used to bake, shape, or dry products. It is fundamentally different from the electric ovens we use at home. It can be said to be two completely different types of products. The following diagram can clearly illustrates the difference between the two.

Industrial ovens are used in factories as part of the production process of a product. For example, when some products need to be tested at high temperatures, industrial ovens are used. It is used to test the parameters and performance of a product or material in a high-temperature environment to determine the reliability of the product or material.

Industrial ovens are generally made of angles and sheet metal to form the outer structure of the box, with drying systems and temperature control series installed inside, etc. Depending on the product, there are certain differences in the structure and function of industrial ovens.

Some industrial ovens are smaller and some are larger, all of which depend on the product to be processed. In general, the industrial oven door is more demanding, so it is important to choose a suitable industrial oven hinge.

What are the requirements of industrial ovens for hinges?

Industrial ovens are used in a special environment, usually with high temperatures and high humidity. So the requirements for the industrial oven hinges will need to be able to withstand high temperature and high humidity performance.

Of course, the hinges are installed on the outside of the cabinet, a high temperature and high humidity environment is better than the interior of the cabinet. So industrial oven hinges can use some common surface treatment can be.

In addition, industrial oven doors are generally heavy, which requires the oven hinges to meet certain requirements for load-bearing performance. Some industrial oven doors weigh hundreds of kilograms, which requires the load-bearing capacity of a single hinge to reach more than a few dozen kilograms. If you want to achieve this load-bearing requirement, you generally need to use stainless steel industrial hinges, the use of stainless steel industrial hinges to support stronger than other materials.

Industrial oven hinge opening angle is also a factor to be considered, according to the actual situation of industrial oven door opening angle is different, some need to open a certain angle can, and some need to open to 180 degrees or even 270 degrees. This is the first factor that needs to be considered, otherwise, the door opening angle can not meet the requirements and is not available.

Industrial ovens have doors that are either flush with the door frame or above it. The hinges used in these two cases are completely different. This has to do with determining the opening angle of the door.

How to choose the material for an industrial oven hinge

As we mentioned above, industrial oven hinges are generally made of iron, zinc alloy, and stainless steel. Depending on the actual situation, we can choose from these three materials. In most cases, we use zinc alloy and stainless steel.

Of course, stainless steel is the best, can be anti-corrosion, and load-bearing performance is also stronger. But when we consider the economic factors, in many cases we can actually use zinc alloy material. Zinc alloy hinges are more affordable and can do more surface treatment to keep the hinges and equipment beautiful as a whole.

The hinges made of zinc alloy can also be very good at preventing corrosion when the surface treatment is done. If your industrial oven is relatively small and the door is light, it is perfectly possible to use hinges made of zinc alloy.

How to choose the surface treatment of industrial oven hinges

The surface treatment of hinges generally varies depending on the material. The surface treatment of stainless steel material is polished, which is the original color of the material. Because there is no need to increase the protection on its surface, stainless steel itself is a very good anti-corrosion property.

Zinc alloys are available in a wide range of finishes, including electroplating, painting, electrophoresis, or other chemical treatments. The purpose is to add a protective coating to the surface of the zinc alloy. Zinc alloys are prone to oxidation and corrosion in the air.

It is necessary to add a layer of protection to its surface to prevent this from happening. Secondly, it can be available in different color finishes so that it can be consistent with the color of the industrial oven and the equipment looks more beautiful.

How to choose the load-bearing size of industrial oven hinges

Load-bearing is an important parameter of industrial oven hinges. If the load-bearing properties do not meet the requirements, the hinges may break over time and the oven door will fall off during use, which would be a very serious accident. So when designing an industrial oven, the importance of the door must be clear, as a way to determine how much weight-bearing hinges are needed.

How do you calculate the weight capacity of a single hinge? We can use a simple way, which is to divide the weight of the door by the number of hinges, which is the weight that a single hinge needs to bear. When we choose a hinge, we use this result as a reference to choose a hinge with a larger load capacity.

For example, a single hinge load-bearing size of 50KG, we choose a single load-bearing hinge greater than 50KG when choosing, so it is more reliable.

Scenarios for industrial oven hinges

The environment in which industrial oven hinges are used depends on the oven equipment. Industrial ovens are mostly used in the factory content, which is indoors. So the indoor environment is to be better than the outdoor, under normal use, industrial oven hinges can be used for at least 10 years.

We know that in the workshop of the factory if the management is not standardized, the noise and dust in the workshop is relatively large. But this does not affect the use of industrial oven hinges, dust does not easily make the hinges corrosive.

Unless the long-term dust accumulation, coupled with the humid air makes the hinge surface dust is not cleaned for a long time, it will be possible to cause the hinge corrosion. However, this situation is very slow and rare.

Therefore, in general, the use of industrial oven hinges is a relatively good environment, after all, not in outdoor use, will not be blown by the wind and sun.

What to do if the industrial oven hinge is broken

What should we do when we encounter a broken hinge in the process of using an industrial oven? The first thing you need to do is to stop the operation of the equipment. And find out the cause of the problem as soon as possible. Remove the damaged hinge in time and reinstall a new one.

If there is a spare hinge in the warehouse. Then the problem can be solved in a short time without delaying the operation of the plant. If there are no spare hinges, then it will take longer to fix the problem.

So we will focus on the fact that it is generally recommended. Customers have a certain amount of inventory for spare parts like these products. Industrial hinges are not a consumable product. But they are a part that can be kept in stock in small quantities. When the hinge is damaged, it can be replaced in a timely manner.

How to Replace Industrial Oven Hinges

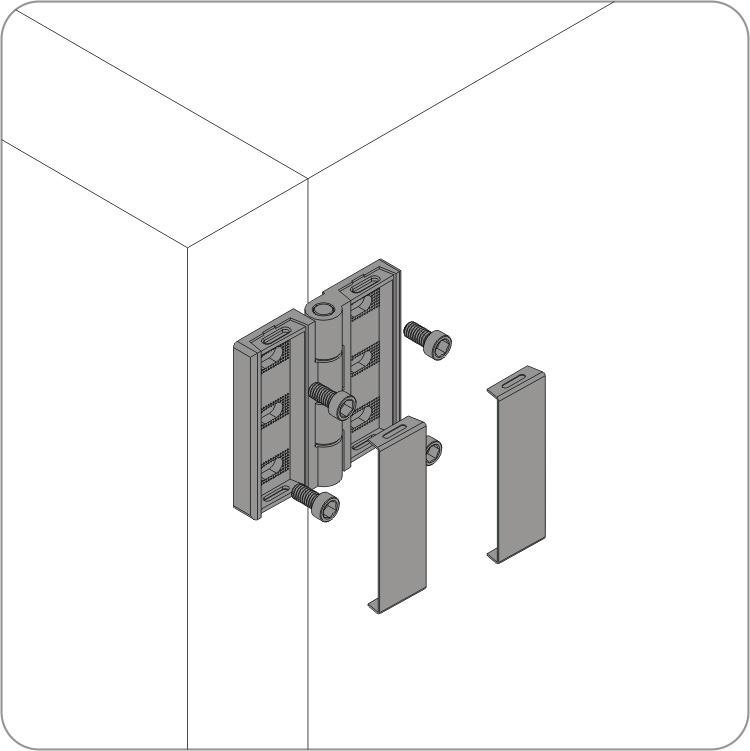

Replacing industrial oven hinges is relatively simple. But care needs to be taken to ensure that the door opens. And closes properly after installation and there are no rattles or deviations. IHINGES industrial oven hinges can generally be adjusted slightly. This is mainly because the mounting holes are long and round so that when adjustments are needed. The holes can be adjusted a little.

During the process of replacing the hinges, someone or something needs to lift the door to a horizontal position. This way the hinges will not be affected by the gravity of the door when they are installed.

Looking for suppliers of industrial oven hinges?

IHINGES is a professional manufacturer of industrial oven hinges. We mainly produce five types of industrial hinges: butt hinges, concealed hinges, heavy-duty hinges, detachable hinges, and cold storage room hinges. Industrial oven hinges mainly belong to docking hinges, heavy-duty hinges, or disassembly hinges.

If you have a need for industrial hinge customization, contact us now.