Ever been in a situation where you’re faced with the task of choosing the right hinge for an industrial application? Perhaps for your industrial oven, large sheet metal boxes, or network cabinets? It’s a challenging process, isn’t it? Especially when you’re bombarded with options and technical specifications that are enough to make your head spin.

To choose a piano hinge, consider the weight it needs to support (load capacity), the length of the hinge for weight distribution, the environmental conditions it will be exposed to, and the type of material that suits these needs. Always ensure the hinge you select enhances the performance and durability of your equipment.

In the following paragraphs, we will delve into the specifics of selecting the right piano hinge for your equipment. Remember, knowledge is power, and we’re here to empower you.

Why are Piano Hinges Important in Industrial Applications?

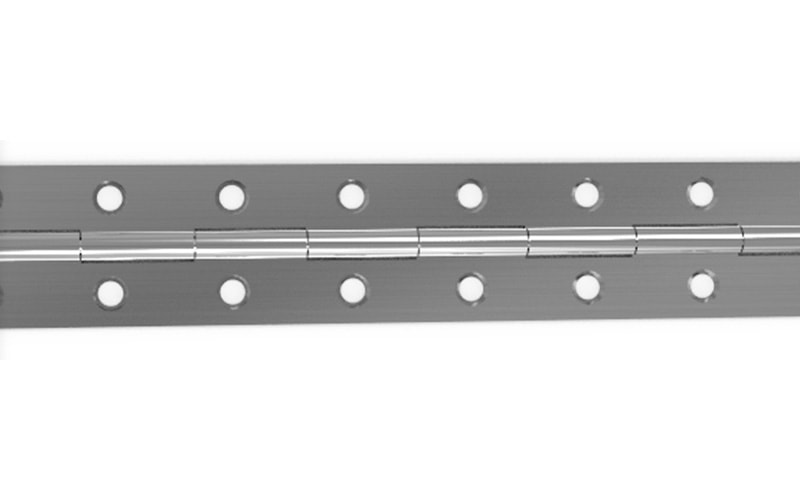

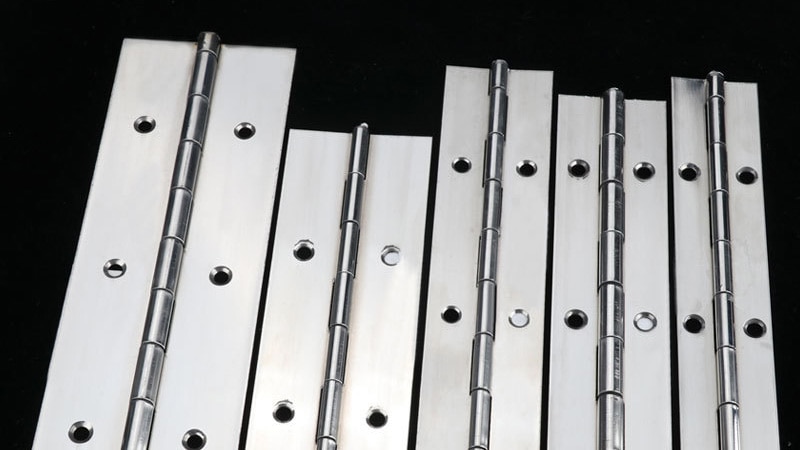

A piano hinge, sometimes called a continuous hinge, is a long, straight hinge that often runs the entire length of the item it is attached to. As a professional hinge manufacturer, IHINGES has proven that these hinges are indispensable in the industrial sector. Why? It’s because they evenly distribute weight and reduce the strain on individual screws, thereby enhancing the durability and longevity of your equipment.

Understanding your application’s requirements is the first step to choosing the right piano hinge. These requirements can include load capacity, length of the hinge, environmental factors, and the material of the hinge. Each of these elements plays a crucial role in the overall performance of your equipment.

What Should I Consider When Choosing a Piano Hinge?

When selecting a piano hinge, the load capacity is a key factor to consider. How much weight does your hinge need to support? Overlooking this aspect can lead to the premature failure of your equipment. Our hinge load capacity calculator can be a helpful tool to determine the correct hinge based on your equipment’s weight and dimensions.

The length of the hinge is another important factor. A longer hinge distributes weight better, providing enhanced support and stability. However, it’s crucial to find a balance. An excessively long hinge may not fit properly or may add unnecessary weight.

How do Environmental Factors and Material Impact My Selection?

Environmental factors can have a significant impact on the durability of your hinge. For example, will your hinge be exposed to corrosive materials or extreme temperatures? If yes, it’s advisable to choose a hinge made from stainless steel or other corrosion-resistant materials.

Different materials offer various benefits. For instance, stainless steel hinges are robust, corrosion-resistant, and ideal for heavy-duty applications, while aluminum hinges are lighter and suitable for less demanding applications. Your choice should be guided by the specifics of your application and the environment in which your equipment will be used.

Conclusion

Choosing the right piano hinge for your industrial application is a crucial yet complex task. It requires careful consideration of your equipment’s requirements, hinge load capacity, length, environment, and material. As an expert in the field, IHINGES is here to help you navigate through this task with ease. Remember, the right hinge can significantly enhance the performance and durability of your equipment.

Don’t let the vast array of options intimidate you. Equipped with the right information, you’ll be making your selection like a pro in no time.