Learn how to easily adjust hidden hinges for optimal alignment and functionality in industrial equipment doors.

To adjust hidden hinges on industrial equipment doors, use adjustment screws for vertical, horizontal, and depth alignment. Loosen the screws slightly, make incremental adjustments, and retighten to ensure precision.

Mastering hinge adjustments ensures smooth operation and extended hinge life. Explore detailed instructions for precise adjustments below.

Understanding Hidden Hinges

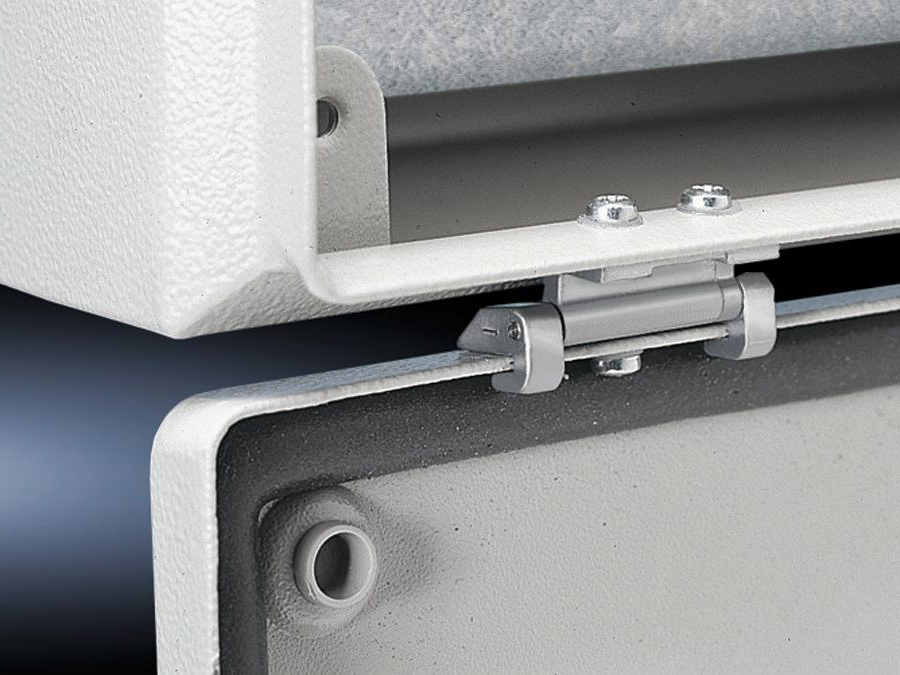

Hidden hinges, also known as concealed hinges, are commonly used in industrial equipment to maintain a seamless appearance while ensuring reliable functionality. Unlike traditional butt hinges, concealed hinges are entirely hidden when the door is closed, making them ideal for equipment where cleanliness and aesthetics are priorities.

These hinges provide smooth, precise door movement and support significant weight, such as in cold storage room hinges or climatic test chamber hinges. Proper alignment is essential to prevent equipment malfunctions caused by misaligned doors, which can also damage the hinges over time.

Tools Required for Adjusting Hidden Hinges

Adjusting hidden hinges requires basic tools, including a flathead or Phillips screwdriver, Allen keys, and a level. In industrial applications, measuring tools such as calipers may also be needed to ensure alignment.

When working with heavy-duty doors or marine hinges, additional safety measures, like wearing gloves and securing the door during adjustments, are crucial. Proper tools and safety practices simplify the adjustment process and minimize the risk of hinge damage.

Identifying Common Adjustment Issues

Hidden hinges may require adjustment due to several common issues, including misaligned doors, uneven gaps between doors and frames, or improper hinge tension. These problems are typically caused by wear, heavy usage, or improper installation.

Recognizing the issue is the first step in making adjustments. For instance, if a door doesn’t close flush, depth adjustment might be necessary. Misalignment vertically or horizontally indicates the need for corresponding adjustments to ensure precision and proper functionality.

Vertical Adjustment

Vertical adjustments fix doors that are too high or low relative to the frame.

Loosen the vertical adjustment screw slightly, reposition the hinge to raise or lower the door, and retighten. Use a level to verify alignment and repeat if necessary.

In industrial equipment featuring trailer door hinges, such adjustments ensure secure sealing and prevent operational issues. Careful measurement and incremental corrections help maintain a professional finish and robust functionality.

Horizontal Adjustment

Horizontal adjustments correct misalignment side to side.

Locate the horizontal adjustment screw on the hinge, loosen it slightly, and slide the door left or right until aligned with the frame. Tighten the screw securely.

For large equipment doors, like those using heavy-duty hinges, this adjustment ensures even spacing and smooth operation. Checking for uniform gaps is essential to maintain aesthetic and functional integrity.

Depth Adjustment

Depth adjustments align the door flush with the frame or equipment surface.

Adjust the depth screw to bring the door closer to or farther from the frame. Check alignment frequently to ensure a seamless fit.

Doors equipped with aluminum hinges or soft-close mechanisms benefit significantly from precise depth adjustments, as these features rely on accurate alignment for smooth functionality.

Adjusting Tension in Hinges

Tension adjustments are critical for self-closing or soft-close hinges used in industrial equipment.

Use the tension adjustment screw to increase or decrease the hinge’s closing force. Ensure the door closes securely but gently without slamming.

Properly adjusted tension prevents wear on both the hinge and the equipment. For example, in environments where special hinges are used, maintaining consistent tension ensures long-term durability.

Adjusting Overlay Hinges

Overlay hinges determine how much the door overlaps the frame, critical in concealed hinge applications.

Measure the overlay and loosen the hinge screws slightly to adjust the hinge position. Re-tighten and verify the overlay is correct.

This is particularly important in precision equipment requiring tight seals, such as cold storage or laboratory setups. Adjustments to detachable hinges often involve similar processes to ensure proper fit and alignment.

Clip-on Hidden Hinge Adjustments

Clip-on hinges simplify installation and adjustments, commonly found in industrial applications requiring frequent access.

Detach the hinge from the mounting plate, make necessary adjustments, and clip it back securely. Adjust screws for fine-tuning if required.

These hinges, often paired with industrial hinge production bases, offer flexibility for frequent maintenance without compromising stability or alignment.

Realigning Multiple Hinges on Large Doors

Heavy doors often have multiple hinges that must be uniformly aligned.

Loosen all hinges slightly, align the door to the frame, and adjust each hinge incrementally. Retighten screws once alignment is achieved.

Equipment utilizing weld-on hinges benefits from this systematic approach, as proper alignment minimizes stress on individual hinges, prolonging their lifespan.

Preventive Maintenance Tips for Hidden Hinges

Regular maintenance ensures concealed hinges remain functional and aligned.

Inspect for wear, lubricate moving parts, and periodically check alignment. Address minor adjustments immediately to prevent larger issues.

In systems like piano hinges used in industrial settings, preventive care ensures smooth operation and enhances durability.

Conclusion

Adjusting hidden hinges on industrial equipment is straightforward with the right tools and techniques. Proper alignment enhances door function and extends hinge life.