Continuous hinges, commonly known as piano hinges, are renowned for their ability to support substantial weight and ensure even load distribution. These hinges are a cornerstone in industrial and commercial applications, offering unparalleled strength and reliability.

A continuous hinge, or piano hinge, supports significant weight, with heavy-duty options holding 200 to 600 lbs or more. Stainless steel models and aluminum geared continuous hinges excel in demanding environments due to their durability and resistance to wear.

Understanding the factors behind their strength and versatility sheds light on why they are the preferred choice for heavy-duty applications.

Key Features That Contribute to the Strength of Continuous Hinges

Continuous hinges achieve exceptional strength due to the thoughtful engineering of their design and materials. They are built to withstand high stress, making them ideal for applications demanding durability.

The strength of continuous hinges comes from their construction using robust materials like stainless steel, precise hinge pin diameter, and even load distribution along their length.

- Material Strength: The most robust continuous hinges, such as stainless steel or heavy-duty aluminum varieties, offer superior tensile strength and corrosion resistance. These materials ensure the hinge can endure repeated use under heavy loads.

- Hinge Pin Diameter: Larger pin diameters enhance durability and resistance to wear, particularly in high-frequency applications.

- Design and Length: Continuous hinges eliminate stress points found in traditional hinges by distributing the load evenly across the entire hinge length.

Compared to butt hinges, piano hinges excel in applications requiring greater durability, thanks to their design and material advantages.

Types of Continuous Hinges and Their Weight Capacity

Different types of continuous hinges are tailored to suit various needs, with weight capacities varying based on the hinge’s construction and purpose.

Heavy-duty piano hinges support weights ranging from 200 to 600 lbs, with specialized options like aluminum geared continuous hinges meeting specific requirements.

- Piano Hinges: Ideal for medium-duty tasks, such as cabinets and light industrial doors, these are versatile but may have lower load capacities compared to heavy-duty models.

- Heavy-Duty Continuous Hinges: These are designed for industrial doors and applications requiring robust support, capable of holding up to 600 lbs or more.

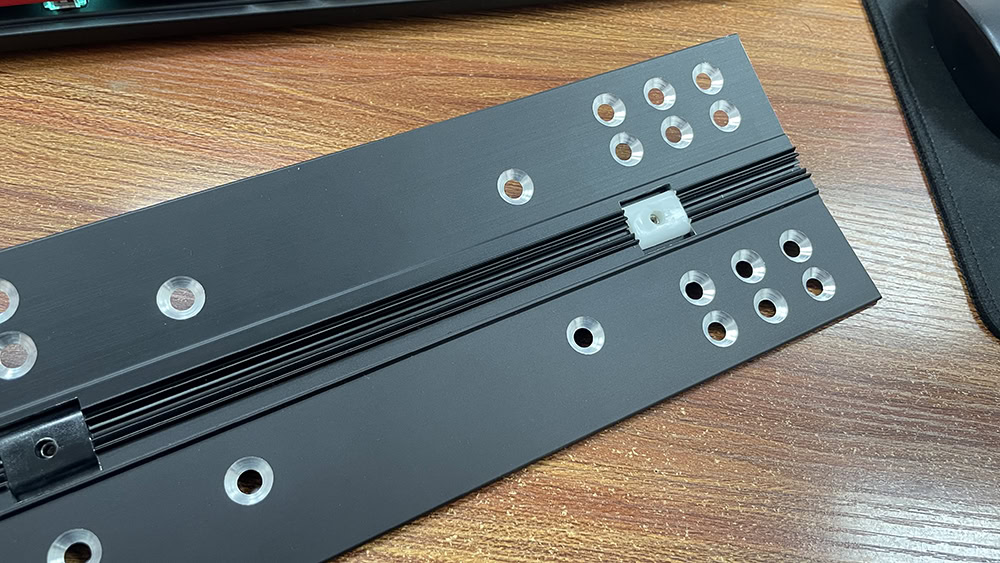

- Aluminum Geared Continuous Hinges: Lighter than stainless steel, these offer a balance of strength and ease of installation, perfect for applications like trailer door hinges.

| Type | Weight Capacity | Applications |

|---|---|---|

| Standard Piano Hinges | Up to 200 lbs | Furniture, light industrial use |

| Heavy-Duty Continuous Hinges | 200-600 lbs | Industrial and security doors |

| Aluminum Geared Continuous Hinges | 200-400 lbs | Lightweight industrial use |

Advantages and Limitations of Continuous Hinges

While continuous hinges are a powerhouse in load-bearing applications, they also have specific limitations to consider.

Continuous hinges offer uniform stress distribution and durability but may require precise installation and incur higher costs.

Advantages:

- Load Distribution: Stress is spread evenly along the hinge, minimizing wear.

- Durability: Built for high-frequency use in demanding environments, such as marine hinges for corrosive settings.

- Aesthetic Integration: Concealed hinges are often used for applications demanding a seamless look.

Limitations:

- Installation Precision: Misalignment during installation can compromise performance.

- Customization: Tailored solutions may require longer lead times.

- Cost: High-quality materials, such as those used in cold storage room hinges, can increase expenses.

Applications of Heavy-Duty Continuous Hinges

Heavy-duty continuous hinges serve a wide range of industries, each leveraging their unmatched strength and reliability.

These hinges are indispensable in industrial equipment, marine environments, and security applications, ensuring durability and smooth operation under heavy loads.

- Industrial Uses: Continuous hinges find use in climatic test chamber hinges and other precision equipment where stability is critical.

- Marine Applications: Stainless steel marine hinges resist corrosion, making them ideal for saltwater environments.

- Security and Heavy Doors: Concealed options provide added protection and a clean finish for high-security doors.

Conclusion

Continuous hinges showcase unmatched strength, especially in industrial applications. With their even load distribution, robust materials, and durability, they remain the go-to choice for heavy-duty solutions. Whether for industrial, marine, or security purposes, their reliability is undeniable.