Replacing industrial-grade door hinges depends on their condition and usage. Identifying the right time for replacement ensures safety, performance, and durability.

Industrial-grade door hinges typically last 7–10 years, depending on usage and maintenance. Replace hinges when you notice misalignment, rust, squeaking, or wear affecting door function and safety.

Learn the key signs and conditions to determine when to replace industrial-grade door hinges for optimal performance and longevity.

Expected Lifespan of Industrial Door Hinges

Understanding how long industrial-grade door hinges last is essential for proper maintenance and planning replacements.

Industrial-grade door hinges last 7–10 years on average, depending on factors like material quality, door weight, and environmental conditions. Regular inspections are crucial.

The lifespan of industrial hinges depends on several factors:

- Material Quality: Heavy-duty materials like aluminum hinges or stainless steel offer longer durability due to rust resistance.

- Frequency of Use: Hinges on high-traffic industrial doors experience faster wear and tear.

- Environmental Exposure: Hinges in humid or corrosive settings deteriorate quicker.

Regular inspections are essential to identify potential issues early and maintain hinge functionality over time. Replace hinges showing signs of rust, wear, or misalignment, even if they haven’t reached their typical lifespan.

Signs You Should Replace Door Hinges

Key indicators suggest it’s time to replace industrial door hinges for safety and performance.

Replace hinges when doors sag, squeak persistently, or have visible rust, misalignment, or difficulty opening and closing.

Signs of failing hinges include:

- Sagging Doors: Often caused by worn pins or bent hinges, leading to improper alignment.

- Corrosion: Rust compromises structural integrity, especially in damp or marine environments, making marine hinges a preferred replacement choice.

- Persistent Noise: Squeaking may result from worn pivot points or lack of lubrication, indicating deterioration.

Ignoring these signs can lead to operational inefficiencies or accidents. Regularly check hinges on doors that bear heavy loads or experience frequent use.

Maintenance Tips to Extend Hinge Lifespan

Proper care can significantly extend the lifespan of industrial-grade door hinges.

Lubricate hinges annually, clean with non-corrosive products, and inspect for wear to maximize their performance and longevity.

To extend hinge life:

- Lubrication: Use silicone or graphite-based lubricants to reduce friction and wear on moving parts.

- Cleaning: Wipe hinges with a soft cloth and non-abrasive cleaner to remove dust and debris.

- Tightening Screws: Ensure screws remain secure to prevent stress on the hinge mechanism.

For environments requiring durability, such as cold storage rooms, cold storage room hinges are ideal due to their resistance to extreme temperatures.

Fixing or Replacing Hinges Without Removing the Door

Replacing hinges without removing the door can save time and effort in industrial settings.

Secure the door with temporary supports, unscrew the old hinge, and replace it with a new one without detaching the door.

Steps to replace hinges:

- Support the Door: Use wedges or a door jack to keep the door stable.

- Unscrew One Hinge at a Time: This maintains door alignment.

- Install New Hinges: Match the same size and screw patterns to ensure compatibility.

This method is particularly effective for heavy industrial doors that use heavy duty hinges and require stability during replacement.

Consequences of Neglecting Hinge Replacement

Failing to replace worn hinges can lead to operational issues and potential safety hazards.

Neglected hinges can cause misaligned doors, increased wear on frames, and even door collapse, risking costly repairs or accidents.

Potential consequences include:

- Damage to Frames: Worn hinges can strain and crack door frames.

- Operational Downtime: Faulty hinges on critical industrial doors may disrupt workflows.

- Safety Risks: Sudden hinge failure on heavy doors could cause injuries or damage.

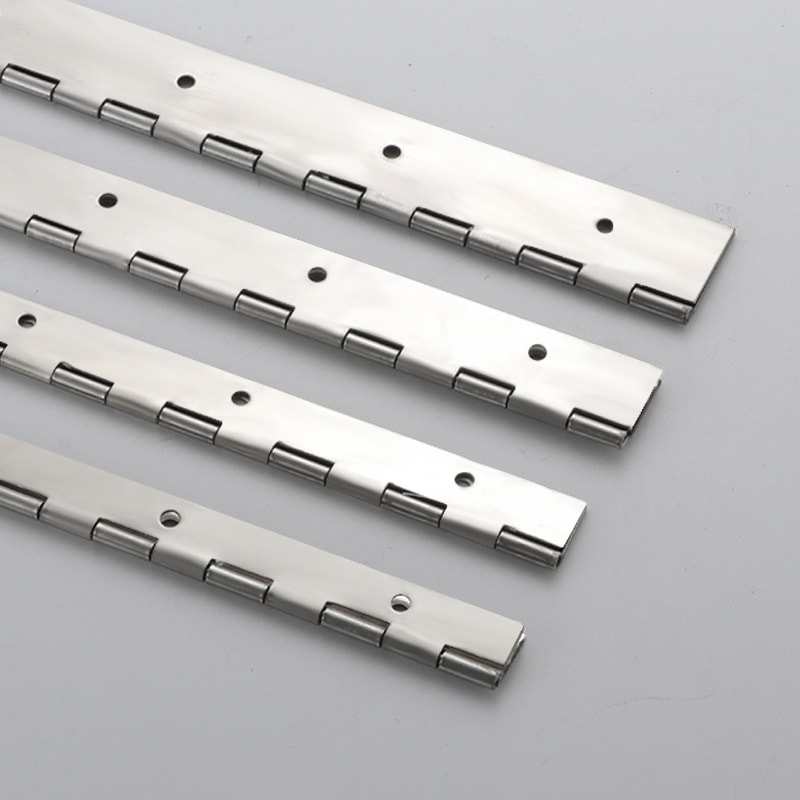

Timely replacements, especially with specialized options like piano hinges for continuous support, help prevent these risks and ensure smooth operations.

Material and Style Considerations for Replacements

Selecting the right material and style ensures hinge replacements suit industrial needs.

Choose corrosion-resistant materials like stainless steel for durability, and ensure hinge styles align with the door’s weight and usage.

Key factors for replacement:

- Material: For corrosive environments, stainless steel or coated aluminum hinges offer long-lasting solutions.

- Hinge Style: Use piano hinges for heavy doors requiring continuous support or concealed hinges for aesthetic purposes.

Selecting the correct hinges maintains door efficiency and ensures compatibility with industrial applications.

Conclusion

Replacing industrial-grade door hinges every 7–10 years, or earlier if signs of wear arise, ensures safety and functionality. Regular maintenance and timely replacements are crucial for optimal performance.