Choosing the right number of hinges for a shed door is essential for ensuring stability, security, and ease of use. Factors such as door size, weight, material, and hinge quality all play critical roles in determining the ideal number of hinges for your specific shed door.

Typically, two or three hinges are recommended for shed doors, depending on the door’s dimensions and weight. Heavier or taller doors benefit from three hinges for additional support, while smaller, lighter doors often need only two. Properly selected hinges and spacing will enhance door stability and longevity.

Selecting the right number and type of hinges can greatly impact your shed door’s performance and security.

Door Weight and Size

Larger or heavier shed doors require more support to prevent sagging and increase durability, making three hinges preferable in these cases.

Heavier shed doors benefit from three hinges, while lighter, smaller doors may need only two for adequate stability. For doors over 6 feet or 80 pounds, three hinges provide a balanced load distribution, reducing strain on each hinge and preventing the door from warping over time.

Using robust heavy-duty hinges for large doors can ensure lasting stability and strength, especially for weather-resistant outdoor sheds. By contrast, smaller or lighter doors can often use two well-placed hinges effectively, especially if they are in a low-traffic or low-use shed.

Shed Door Material

The material of the shed door affects how many hinges are needed to support it adequately. Heavier materials, such as metal or solid wood, typically require additional hinges to ensure proper support.

Solid wood or metal shed doors require three hinges for stability, as these materials add significant weight. Lightweight materials like plywood or PVC can often function well with two hinges if the door is under 50 pounds. For exceptionally heavy materials, you may want to consider specialized options like marine hinges for added corrosion resistance, especially in outdoor settings.

Comparing door materials and their respective weights helps you select hinges that can handle the load without compromising durability.

Types of Hinges for Shed Doors

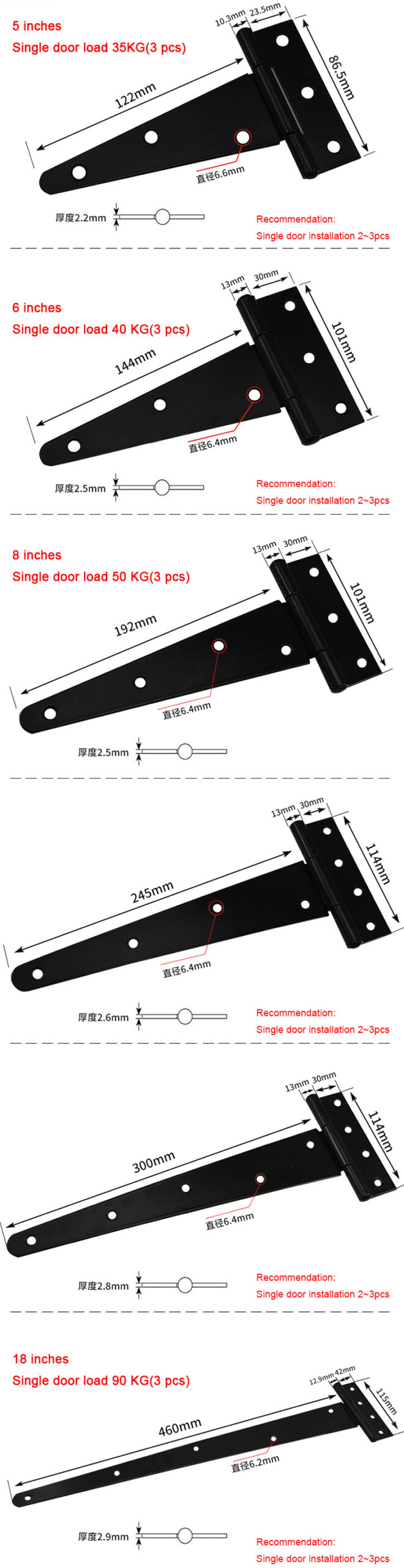

Selecting the correct hinge type is as crucial as choosing the right number of hinges. The most common types include T-hinges and butt hinges, which provide robust support for most shed doors.

T-hinges and butt hinges are popular choices for shed doors due to their load-bearing abilities and versatility. T-hinges, with their extended mounting plates, offer greater stability for larger or heavier doors, while butt hinges are suitable for standard-sized doors and are easy to install. Heavy-duty hinges, such as those used for industrial applications, provide extra durability for high-traffic shed doors and are more resistant to environmental conditions.

Choosing between these hinge types allows you to tailor the hinge setup to the specific needs of your shed.

Security Needs

Security is an essential consideration when choosing hinges for a shed door, especially if valuable items are stored inside.

Security hinges or hidden hinges are often recommended for shed doors that open outward, as they can deter tampering. Standard external hinges may be vulnerable to removal or forced entry, so using hidden hinges or security models is advisable. Anti-theft hinges, with specialized designs to prevent tampering, and hidden hinges are popular choices for sheds storing high-value items.

If security is a concern, prioritize hinge types designed to prevent unwanted access to the shed.

Door Usage Frequency

The frequency with which a shed door is used impacts the hinge requirements. Doors that are used frequently benefit from additional hinges to handle the repeated strain.

High-use shed doors generally need three hinges to withstand constant opening and closing. Heavy-duty hinges are recommended for such applications to minimize wear. If your shed is for tool storage or daily use, the door will put more strain on each hinge, making it essential to have robust hinge support to ensure long-term functionality.

This will prevent hinge loosening or door misalignment over time.

Hinge Placement and Spacing

Proper hinge spacing ensures even weight distribution across the door, reducing strain on individual hinges.

Space hinges evenly along the door length to provide optimal support. For doors using three hinges, position one near the top, one at the bottom, and one in the center. This setup distributes weight evenly and minimizes sagging. For smaller doors with two hinges, place them at the top and bottom with an even gap between.

Using high-quality aluminum hinges or weld-on hinges can further enhance the door’s stability and help prevent misalignment.

External or Internal Hinge Placement

The location of the hinges, whether internal or external, can affect the door’s security and longevity.

External hinges are common but expose the door to security risks, as they can be tampered with or removed. To increase security, opt for internal or hidden hinges that conceal the hardware, making it more difficult to tamper with. Hidden hinges are also a good choice for weather resistance, as they remain protected from the elements, reducing rust or wear.

Choosing the right placement depends on the level of security and exposure needed for your specific shed.

Do Shed Doors Open Inward or Outward?

Most shed doors open outward for practical space-saving and ventilation reasons, which impacts hinge choice.

Outward-opening shed doors typically require external hinges, as this orientation offers more ventilation and easy access. However, external hinges can expose the door to tampering. Hidden hinges provide a more secure option for outward-opening doors, as they remain inaccessible from the outside.

Understanding door orientation helps in selecting hinges that enhance the shed’s security and functionality.

Weather Resistance

Since shed doors are exposed to the elements, selecting weather-resistant hinges can extend their lifespan and improve performance.

Outdoor hinges should be made of weather-resistant materials, like galvanized steel or stainless steel, which resist rust and corrosion. For sheds in humid or coastal areas, marine-grade hinges are ideal for preventing damage due to moisture. These materials are designed to withstand extreme weather conditions and extend the door’s life.

Weather-resistant options are crucial to ensure your shed door performs well over time.

DIY Tips for Shed Door Hinges Installation

Proper installation techniques can enhance the security and stability of your shed door hinges.

Accurate measurements and high-quality screws are essential for a secure installation. Use a template to align hinges evenly and ensure the door fits snugly in the frame. Heavy-duty or soft-close hinges can prevent slamming, especially for metal or heavier wooden doors, and provide a quieter, smoother operation.

Following these tips can help you achieve a sturdy, long-lasting shed door installation.

Conclusion

Choosing the right number and type of hinges for a shed door involves balancing stability, security, and functionality. Considering factors like door weight, material, and security needs helps ensure a door that performs reliably over time.