Soft close hinges provide a quiet, controlled way for doors to close, improving durability and reducing noise. They are ideal for homes, offices, and industrial applications due to their smooth functionality and ability to protect cabinetry from wear and tear.

Soft close hinges work by using a hydraulic mechanism that slows the door’s movement as it nears the frame, enabling silent and gentle closures. The hinge’s built-in damper absorbs energy, which reduces impact and noise, making soft close hinges particularly useful in noise-sensitive environments like kitchens and offices.

These hinges enhance user experience and prolong the lifespan of cabinetry. Read on to understand their mechanism, installation, adjustment, and maintenance.

Understanding Soft Close Hinge Mechanisms

The hinges employ a hydraulic damper, which uses fluid pressure to manage the door’s closing speed.

Soft close hinges function by using hydraulic pistons within the hinge arm to control closing speed, creating a smooth and silent effect.

How Soft Close Hinges Work in Depth

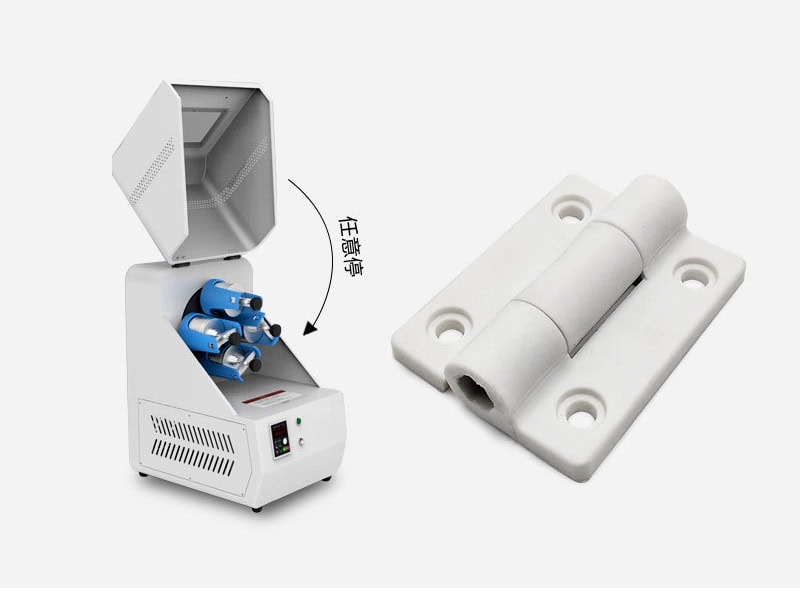

Soft close hinges have a small hydraulic damper inside the hinge arm. This component absorbs kinetic energy as the door closes, allowing it to move gently without slamming. Hydraulic fluid in the damper provides resistance that counteracts rapid movement, maintaining functionality even with heavy or frequently used doors. This feature makes soft close hinges popular across a range of applications, from cold storage room hinges to kitchen cabinetry.

Difference Between Soft Close and Self-Close Hinges

Soft close and self-close hinges differ significantly in their mechanisms and applications, with each hinge serving unique needs.

Soft close hinges feature hydraulic damping for noise control, while self-close hinges use springs, resulting in louder closures.

Comparing Soft Close to Self-Close Hinges

While both hinge types encourage doors to close automatically, soft close hinges use dampening technology to achieve quieter operation. This makes soft close ideal for places like offices and homes. Self-close hinges, often spring-loaded, provide a more forceful closure suited to environments where noise control isn’t critical, like industrial facilities. For specific uses, like heavy duty hinges, soft close options may be preferable due to their quieter function.

Advantages of Soft Close Hinges

Soft close hinges have multiple benefits, such as enhanced durability and reduced noise, making them a valuable choice for various settings.

Soft close hinges prevent slamming, lower noise levels, and extend the life of cabinetry by controlling door impact.

Benefits of Soft Close Hinges for Everyday Use

Soft close hinges not only extend the life of cabinetry but also enhance safety by preventing doors from slamming shut on fingers. This makes them suitable for high-traffic areas and family homes. Additionally, they improve the user experience by reducing daily noise levels. From residential cabinetry to industrial doors, soft close features enhance functionality, even for industrial hinge production base use cases.

Disadvantages of Soft Close Hinges

While beneficial, soft close hinges have certain drawbacks, including higher costs and potential hydraulic maintenance needs.

Soft close hinges may require maintenance over time, can be expensive, and are slightly more complex to install than regular hinges.

Detailed Drawbacks of Soft Close Hinges

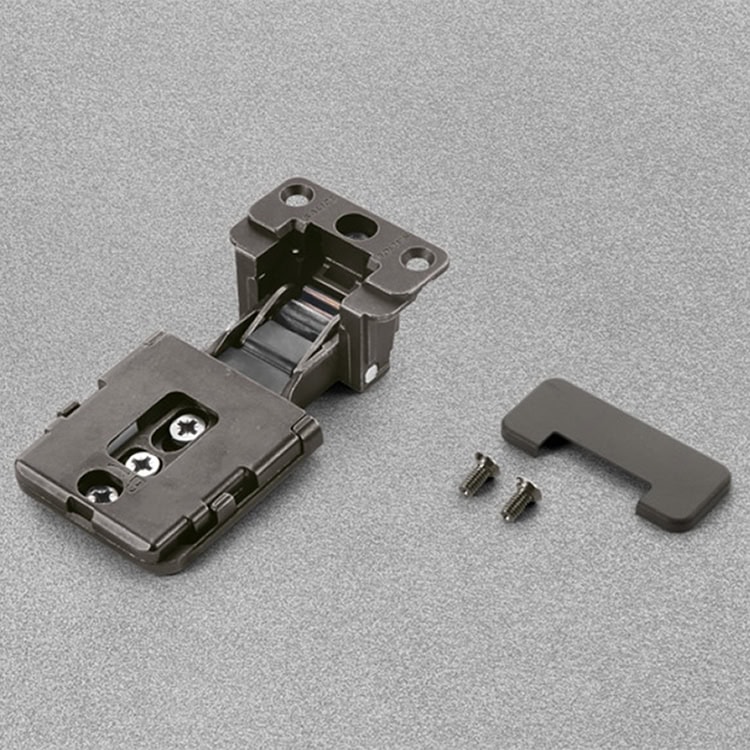

Soft close hinges, though effective, are pricier due to their advanced damping mechanism, which may also need occasional maintenance. Hydraulic components within the hinge may wear out over time, affecting performance. Installation can be more challenging, as precise alignment is required for proper function. Despite these drawbacks, the benefits often outweigh these minor disadvantages, especially in applications like piano hinges, where smooth functionality is essential.

Common Issues with Soft Close Hinges

Soft close hinges, like any mechanical device, may encounter issues such as decreased damping performance or misalignment over time.

Typical issues with soft close hinges include hydraulic failure, alignment problems, and adjustments that may need regular attention.

Troubleshooting Soft Close Hinge Issues

Frequent issues with soft close hinges arise from hydraulic dampers wearing out, which can prevent smooth operation. Loose screws may cause alignment issues that impact the damping mechanism. To resolve these issues, inspect hinge components regularly for misalignment or worn parts. Maintenance of soft close hinges extends their useful life and reduces the likelihood of needing a full replacement.

How to Adjust Soft Close Hinges

Most soft close hinges have an adjustment feature that lets users control how quickly the door closes.

Adjusting soft close hinges involves turning the tension screw on the hinge arm to control the door’s closing speed.

Step-by-Step Soft Close Adjustment Guide

Adjustment screws located on the hinge arm allow for easy control of damping speed. To slow the closing speed, rotate the screw counterclockwise; to increase speed, turn it clockwise. Proper adjustment ensures smooth closure and prevents slamming. Regular adjustments keep the hinge working optimally, especially for concealed hinges where visibility of hinge functionality is minimal.

Hinges Compatibility with Push to Open

Soft close hinges can be used with push-to-open mechanisms, though adjustments may be necessary.

Push-to-open and soft close systems are compatible, offering combined functionality with minor adjustments.

Combining Soft Close with Push-to-Open

When combining soft close and push-to-open features, slight adjustments to tension can prevent potential conflicts between systems. This combination is common in modern cabinetry where accessibility and noise reduction are both priorities. Proper setup enhances the convenience and ease of cabinet doors, creating a seamless user experience.

Installing

Soft close hinges require precise alignment and secure attachment for optimal performance.

Soft close hinges can be installed by aligning with the door and frame, and tightening screws to secure stability.

Installation Steps for Soft Close Hinges

To install soft close hinges, align the hinge plate with the cabinet frame, ensuring it is flush. Secure screws for stability, and test the hinge function to confirm proper closure. This process may vary slightly depending on hinge type but remains generally straightforward. Careful installation enhances hinge performance and longevity, especially for robust applications like marine hinges that require reliable operation.

Maintenance Tips

Routine maintenance helps extend the life of soft close hinges, ensuring continued performance and quiet operation.

Maintaining soft close hinges involves cleaning, checking tension screws, and lubricating parts as needed to prevent hydraulic failure.

Regular Care for Long-Lasting Performance

Periodic cleaning prevents dust buildup that may interfere with hydraulic components. Adjusting tension screws and applying lubrication to metal parts minimizes wear. Regular maintenance also identifies minor issues before they worsen, keeping hinges functional and reducing the risk of costly repairs.

Repair and Replacement

When soft close hinges fail to function, repair or replacement may be required, depending on the severity of the issue.

Soft close hinges can be repaired by checking dampers and alignment; if worn, replacement may be necessary.

Repairing or Replacing Soft Close Hinges

To repair soft close hinges, inspect for worn dampers or loose screws that may affect performance. Often, adjusting the hinge tension and cleaning internal parts can restore function. However, if the hydraulic mechanism is significantly damaged, replacement is recommended. Replacing hinges with quality parts ensures continued performance and enhances durability for demanding applications.

Conclusion

Soft close hinges combine hydraulic technology and noise control, making them an ideal choice for doors requiring smooth and quiet closures. Proper installation, adjustment, and regular maintenance enhance their lifespan and reliability.