In every corner of our world, hinges play a silent but critical role. Whether facilitating movement in massive industrial machines or in a door at your home, they’ve proved indispensable. Yet, not all hinges are created equal. The demands of an industrial setting often lead to distinctive hinge designs that contrast starkly with those intended for residential use.

Industrial hinges differ from residential hinges primarily based on their construction, application, and durability. While both serve the essential purpose of joining two objects and allowing rotational movement, industrial hinges are crafted from more robust materials, tailored for heavy-duty applications and harsh environments. In contrast, residential hinges prioritize aesthetics and are designed for lighter loads typical in a household setting.

Read on and I’ll share the difference between the two in detail for you.

Material Choices

Industrial hinges are frequently made from robust materials like stainless steel, brass, or even specialized alloys. These materials are chosen for their durability, resistance to environmental factors, and ability to handle heavier loads. They can withstand extreme conditions like high temperatures, corrosion, or aggressive chemical environments.

Residential hinges, on the other hand, prioritize aesthetics and cost-efficiency. Materials like brass, zinc, and steel are common, offering decent durability for household use but may not endure in harsher conditions like those encountered in industrial applications.

Load Bearing Capacity

When it comes to bearing heavy loads, industrial hinges stand out. They’re designed to handle extreme weight, be it heavy machinery, large gates, or equipment. Their design parameters ensure they don’t buckle under pressure, providing both strength and flexibility.

In contrast, residential hinges are calibrated for lighter loads such as interior doors, cabinets, or windows. Their load-bearing capacity aligns with the typical demands of a home setting and might not fare well under industrial-level stress.

Durability and Lifespan

Industrial hinges are manufactured with a prolonged lifespan in mind. Given the high costs associated with industrial equipment maintenance and replacements, these hinges are built to last, withstanding wear and tear for extended periods.

Residential hinges, while durable in a home setting, have a comparatively shorter lifespan. They’re not designed to endure the same levels of continuous strain and may require more frequent replacements.

Size and Scale

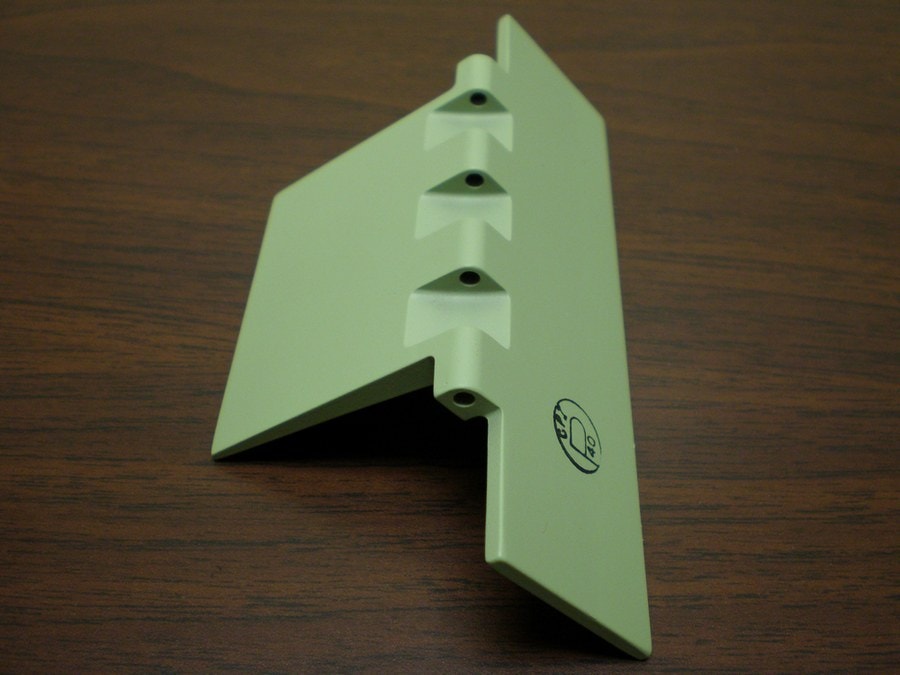

Given the heavyweight applications they’re involved in, industrial hinges are generally larger and more robust. Their dimensions and design aspects cater to their purpose—supporting heavy machinery or facilitating movement in large industrial settings.

Residential hinges are smaller and more discreet, fitting seamlessly into the design aesthetics of a home. Their scale is in tandem with their function, which revolves around lighter applications.

Maintenance Requirements

Routine maintenance is critical for industrial hinges, given their exposure to rigorous operations. Lubrication, regular checks, and preventive measures help in prolonging their operational life.

Conversely, residential hinges require minimal maintenance. Occasional lubrication and checks suffice for their optimal functioning.

Security Considerations

Security is paramount in industrial settings. Hence, industrial hinges often incorporate features that enhance safety and reduce tampering risks. They may be equipped with security pins or be weldable to deter unauthorized access.

In a residential context, while security is essential, the measures are less intensive. Hinges might include basic safety features but lack the advanced mechanisms present in their industrial counterparts.

Environmental Resistance

Industrial hinges often come with enhanced resistance to environmental factors. Whether it’s corrosion, extreme temperatures, or chemical exposure, they’re built to endure. Special coatings or treatments are applied to enhance their resilience.

Residential hinges might have basic protective layers against moisture or rust, but they aren’t equipped to handle industrial-grade environmental challenges.

Customization and Flexibility

Industries might have specialized needs, necessitating custom hinge designs. Industrial hinges offer a higher degree of customization in terms of size, load-bearing capacity, and material.

Residential hinges, meanwhile, offer variations more in terms of aesthetics and design rather than functional customizations.

Conclusion

While hinges, in essence, serve a pivotal role in both industrial and residential settings, the differences in their design, material, and functionality are profound. Recognizing these distinctions ensures that each hinge type is employed in its appropriate setting, optimizing performance, safety, and durability.

You might also be interested: