Field gate hinges play a crucial role in the industrial manufacturing sector, allowing heavy gates to function seamlessly. Selecting the right hinge can be a challenging task, with various factors to consider such as materials, weight capacity, and customizability.

Field gate hinges are specially designed for industrial applications, providing robust support and allowing for smooth operation. Choosing the right hinge ensures longevity and efficiency in gate operation.

In this comprehensive guide, we will explore the intricate details of field gate hinges and what sets them apart in the industrial sector. Let’s delve into the subject.

What Are the Types of Field Gate Hinges?

Field gate hinges come in various types, each catering to different industrial needs and specifications. Understanding these types can help you make an informed decision.

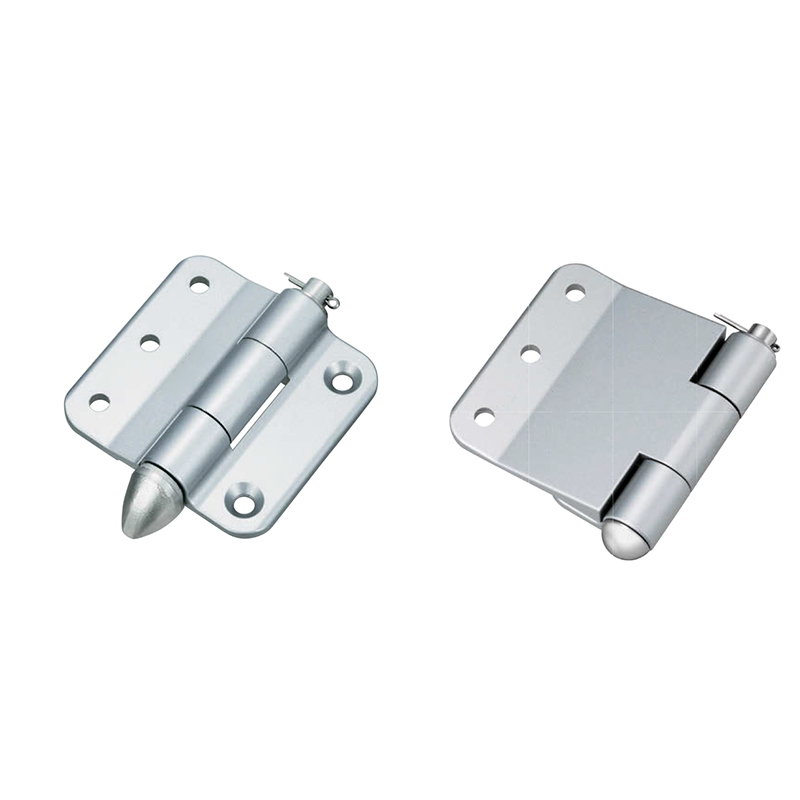

Heavy-duty hinges are built for large gates, offering incredible strength and durability. Often used in industries like shipping and mining, they are known for their resilience against environmental conditions. The choice of materials, such as steel or heavy alloy, ensures they can withstand enormous pressure without losing functionality.

On the other hand, adjustable field gate hinges offer flexibility in alignment and positioning. These hinges provide the ability to adjust the gate’s angle, making them suitable for uneven terrains or unique gate designs. With adjustable hinges, it’s possible to maintain smooth operation and secure fitting even when the surrounding conditions change.

How to Select the Right Field Gate Hinge?

When choosing a field gate hinge, several critical factors come into play. Considering these aspects can lead to a more efficient selection process.

Material selection is paramount for field gate hinges. Depending on the industrial application, you may need hinges made from corrosion-resistant materials like stainless steel or treated alloys. Such materials ensure a longer lifespan, even in harsh industrial environments. It’s crucial to understand the specific needs of your project before deciding on the material.

Load capacity is another vital factor. Knowing the weight and size of the gate helps in selecting hinges that can handle the load without failure. Underestimating the weight capacity can lead to malfunctions, causing delays and increased maintenance costs. Therefore, accurate calculations and professional guidance are essential in choosing the right hinge based on the load capacity.

How to Install and Maintain Field Gate Hinges?

Installation

Proper installation of field gate hinges is critical for achieving optimal performance.

Correct alignment and positioning of the hinges ensure that the gate functions smoothly without unnecessary friction. Professional installation, guided by clear instructions, ensures that the hinges are fitted accurately and securely. Adequate tools and precision are required to achieve a successful installation, reflecting the overall performance of the gate.

Maintenance

Regular maintenance of the hinges can prolong their life and efficiency.

Routine inspections for wear and tear, lubrication, and adjustments are vital for maintaining optimal performance. Regular maintenance schedules conducted by skilled technicians ensure that the hinges remain functional and efficient. This preventive approach can save significant time and costs in the long run, as small issues can be identified and corrected before escalating into major problems.

What Are the Customization Options for Field Gate Hinges?

In the industrial sector, customization plays a vital role, allowing field gate hinges to cater to specific requirements.

The ability to customize the size, material, and design of the hinges enables a tailored approach to individual projects. Custom hinges allow for intricate detailing and specific load-bearing capacities, meeting the unique demands of each application.

Collaboration with manufacturers in the customization process ensures that the end product aligns with the project’s requirements. A detailed understanding of the project’s needs, combined with expert guidance from the manufacturer, facilitates a successful customization process that fulfills the specific demands of the industrial application.

Conclusion

Field gate hinges are essential components in the industrial manufacturing sector. Their types, selection criteria, installation, maintenance, and customization options offer a comprehensive understanding of how they function and their importance in various applications. By considering these factors, you can select the right hinge that meets your specific industrial needs.

You might also be interested: