In a world where industrial manufacturing is in a constant state of evolution, hinges play a surprisingly pivotal role. The right hinge not only provides support and connection but also ensures durability, strength, and adaptability. Among the numerous materials used to create hinges, acrylic emerges as a distinct and valuable option.

Acrylic hinges offer a blend of flexibility, clarity, and resilience, making them indispensable for various industrial applications. Their transparency and robustness stand out, particularly in contexts where visual aesthetics and durability go hand in hand.

For professionals in the industrial manufacturing sector, understanding the features and benefits of acrylic hinges is essential. Let’s delve deeper into the specifics.

1. Transparency and Aesthetics

Acrylic, by its very nature, is transparent. This feature makes acrylic hinges perfect for applications where the visibility of the component is crucial.

For instance, in machinery casings or transparent equipment boxes, acrylic hinges provide an unobtrusive and streamlined appearance. It allows equipment operators to have a clear view without any hindrance.

2. Lightweight Yet Durable

Despite their lightweight nature, acrylic hinges boast a commendable durability. This is especially valuable in industrial settings where the weight of components can impact the machinery’s overall efficiency.

The lightweight characteristic ensures that there is minimal stress on the attached components, while the durability guarantees a long-lasting performance, even in rigorous industrial environments.

3. UV Resistance

In industrial applications where equipment is exposed to sunlight or UV rays, UV resistance becomes vital. Acrylic inherently resists the harmful effects of UV light.

This resistance ensures that the hinge won’t degrade or yellow over time, maintaining its visual appeal and structural integrity despite prolonged UV exposure.

4. Chemical Resistance

Industrial environments often expose machinery to various chemicals. The ability of acrylic hinges to resist certain chemicals can prove advantageous.

While it’s important to note that they aren’t immune to all chemicals, acrylic hinges can resist a range of substances, making them suitable for many industrial contexts.

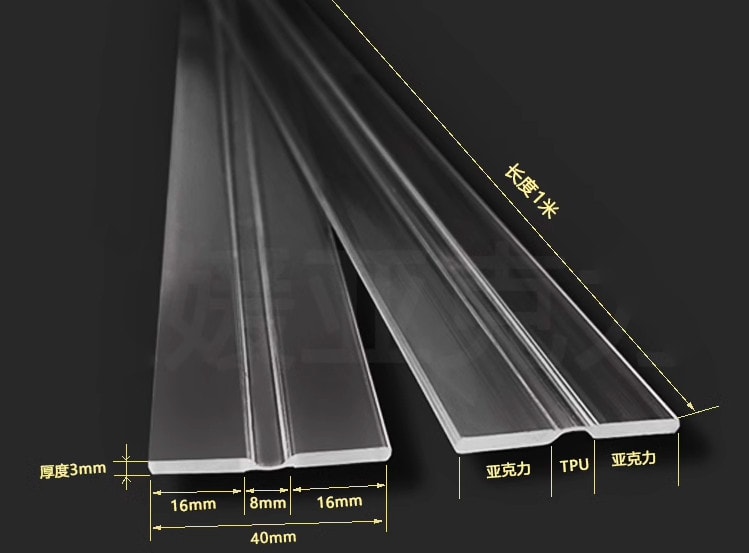

5. Flexibility

Acrylic hinges offer a degree of flexibility not found in many other materials. This makes them adept at handling slight misalignments or structural shifts.

Their elasticity ensures that they can adapt to varying pressures and alignments, reducing the risk of breakage or damage in fluctuating conditions.

6. Easy Customization

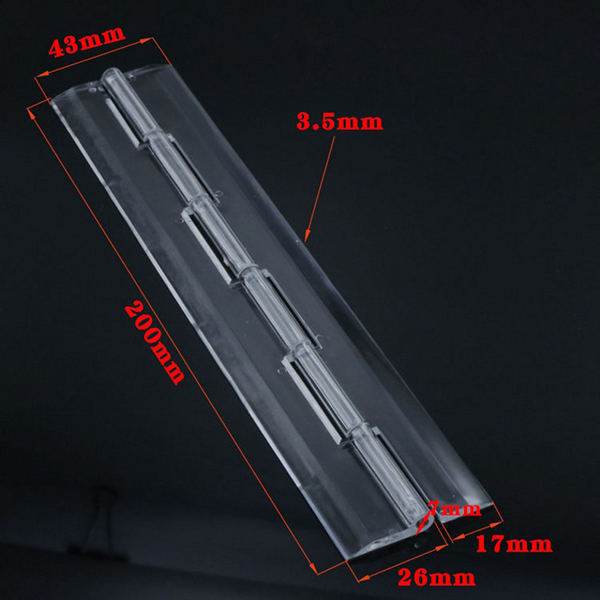

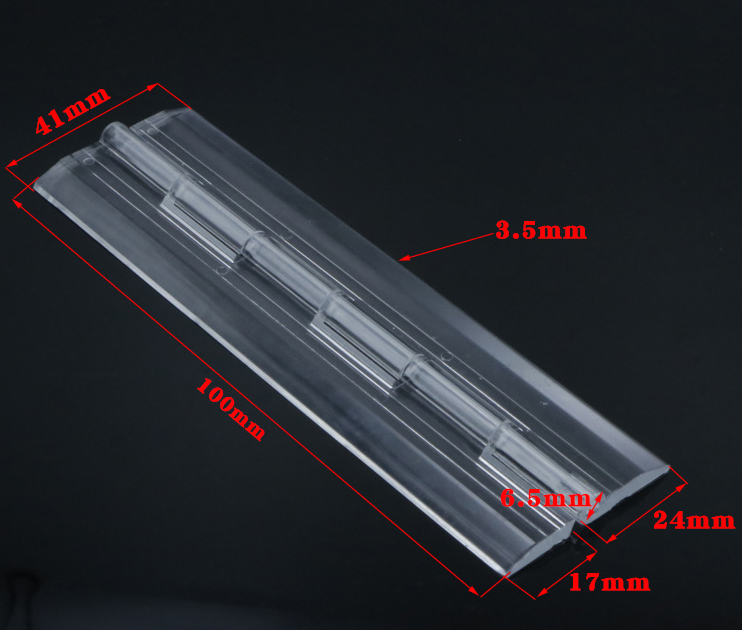

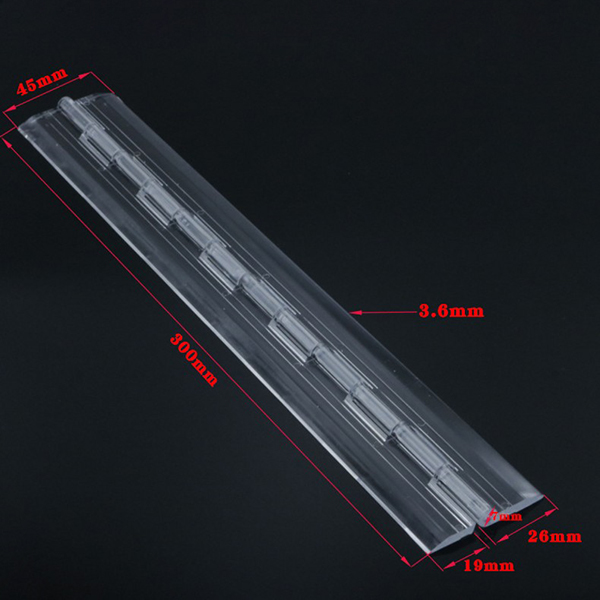

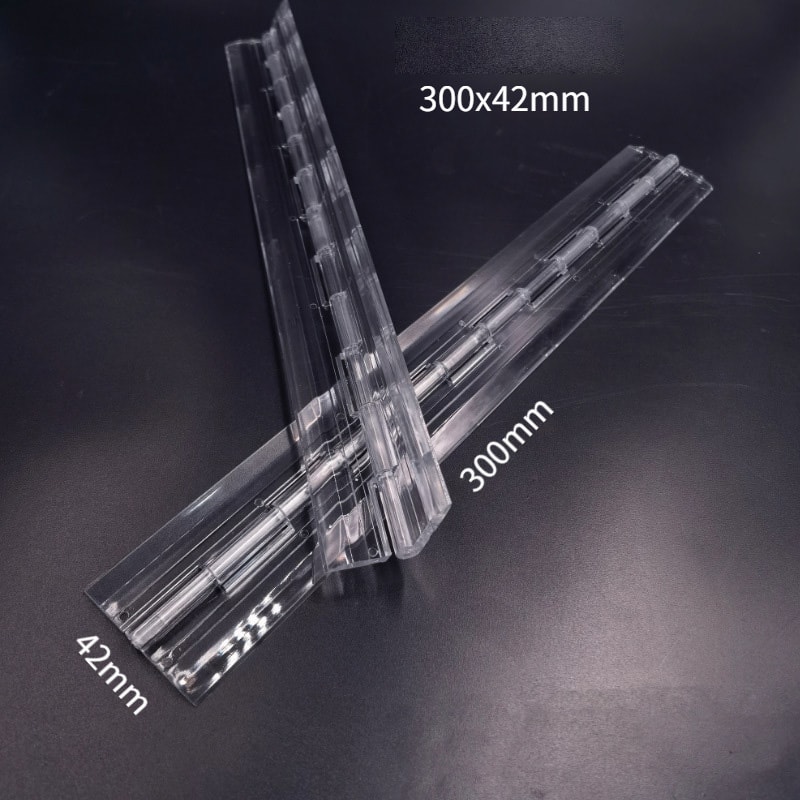

Given the versatile nature of acrylic, it’s relatively simple to customize these hinges according to specific requirements. This is particularly beneficial for unique industrial applications.

Whether it’s about adjusting the size, shape, or drilling patterns, acrylic hinges can be tailored to fit the exact needs of the project at hand.

7. Cost-Effective

In the realm of industrial manufacturing, cost efficiency without compromising on quality is paramount. Acrylic hinges provide a cost-effective solution without skimping on the benefits.

Their production does not require extensive resources, making them an affordable yet high-performing choice for various applications.

8. Environmentally Friendly

Sustainability is becoming increasingly significant in all sectors, including industrial manufacturing. Acrylic hinges have the advantage of being recyclable.

This means that at the end of their lifespan, instead of contributing to waste, they can be repurposed, making them a more environmentally-conscious choice.

Conclusion

In the dynamic world of industrial manufacturing, the importance of every component, no matter how seemingly insignificant, cannot be overstated. Acrylic hinges, with their myriad of benefits from transparency to environmental friendliness, stand as a testament to how evolving materials can make a significant difference. As industries continue to advance and adapt, it’s clear that these hinges will maintain a pivotal role in many applications.

You might also be interested: