Heavy-duty flush hinges are an important component in ensuring the strength and durability of doors, gates, and cabinets. From their design and materials to their weight capacity. These hinges play a crucial role in supporting heavy loads and providing long-lasting performance. This article explores the various aspects of heavy-duty flush hinges and their applications.

What is a flush hinge?

A flush hinge is a type of hinge that sits flush with the surface of the door and frame. Allowing the door to swing open and closed without any protrusions. This type of hinge is often used on cabinet doors. Where the hinge is hidden from view and a clean, seamless appearance is desired. Flush hinges are also commonly used on interior doors, where a minimalist look is desired.

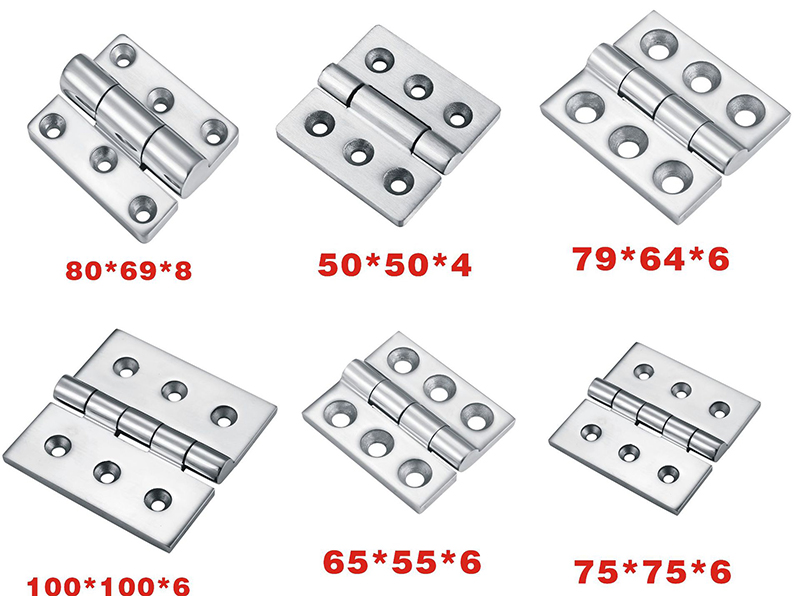

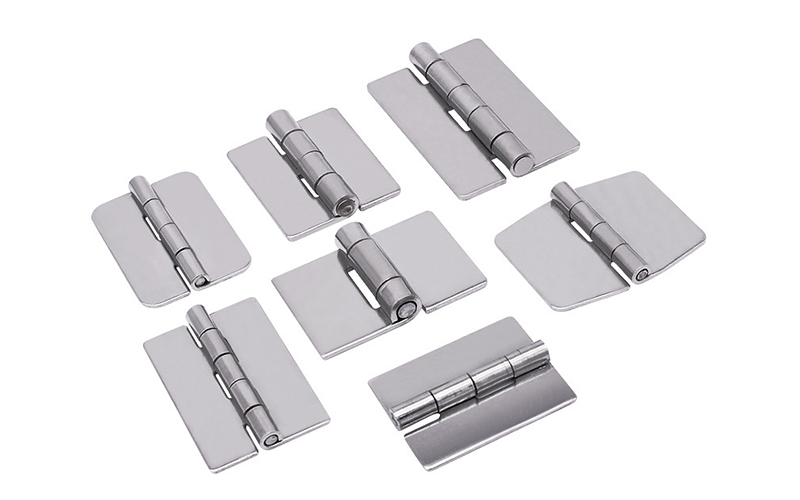

Flush hinges can come in a variety of sizes, shapes, and materials, and can be either mortised into the door and frame or surface-mounted. Mortised flush hinges are installed by cutting a recess or mortise into the door and frame. Allowing the hinge to sit flush with the surface. Surface-mounted flush hinges, on the other hand, are installed directly onto the surface of the door and frame.

Are flush hinges strong?

Flush hinges can be quite strong, depending on their size and material. However, because they sit flush with the surface of the door and frame. They may not be as strong as other types of hinges, such as butt hinges or continuous hinges, which are designed to bear heavy loads. Flush hinges are typically used on lightweight doors. Such as cabinet doors or interior doors, where strength is not a primary concern.

To ensure the strength and durability of flush hinges. It is important to choose high-quality materials and to select a hinge that is appropriately sized for the door. It is also important to properly install the hinge, using the appropriate screws and ensuring that the hinge is securely fastened to both the door and the frame.

What makes a hinge heavy-duty?

A hinge is considered heavy-duty when it is designed to bear a significant amount of weight or when it is intended for use in high-traffic areas. Heavy-duty hinges are typically made from stronger materials than standard-weight hinges and may have additional reinforcement. Such as thicker gauge metal or reinforced joints.

Heavy-duty hinges may also have specific features that make them more durable and reliable. Such as grease fittings or ball bearings that help to distribute weight and reduce friction. Heavy-duty hinges are often used on commercial doors, such as those found in schools, hospitals, and government buildings, as well as on large, heavy doors, such as those found in barns or industrial facilities.

What is the strongest type of hinge?

The strongest type of hinge is a continuous hinge, also known as a piano hinge. A continuous hinge runs the entire length of the door or frame, distributing weight evenly and providing added support and stability. Continuous hinges are typically made from heavy-gauge steel or stainless steel and are designed to bear heavy loads.

Because continuous hinges are so strong and durable, they are often used on high-traffic doors, such as those found in schools, hospitals, and other commercial buildings. They are also commonly used on heavy doors, such as those found on industrial facilities or on large equipment enclosures.

How much weight can a heavy-duty hinge hold?

The weight capacity of a heavy-duty hinge can vary depending on the size and material of the hinge, as well as the specific application. Generally speaking, heavy-duty hinges are designed to bear significantly more weight than standard-weight hinges, with weight capacities ranging from several hundred pounds to several thousand pounds.

To ensure that a heavy-duty hinge is able to bear the necessary weight, it is important to carefully consider the size and weight of the door, as well as the frequency of use and the conditions in which the door will be used. It is also important to choose a hinge that is appropriately sized for the door and to properly install the hinge to ensure maximum strength and durability.

What is the difference between standard-weight and heavy-weight hinges?

The main difference between standard-weight and heavy-weight hinges is their weight capacity. Standard-weight hinges are designed to bear light to moderate loads, typically ranging from 30 to 75 pounds. Depending on the size and material of the hinge. These types of hinges are commonly used on interior doors. Such as bedroom doors or closet doors, where the weight of the door is relatively light.

Heavy-weight hinges, on the other hand, are designed to bear much heavier loads, typically ranging from 100 to several thousand pounds. Depending on the size and material of the hinge. These types of hinges are commonly used on exterior doors, such as front doors or garage doors. As well as on commercial doors, such as those found in schools, hospitals, and government buildings.

In addition to their weight capacity, heavy-weight hinges may also have other features that distinguish them from standard-weight hinges. Such as thicker gauge metal, and reinforced joints. And ball bearings or grease fittings to reduce friction and distribute weight more evenly. Heavy-weight hinges may also have specific finishes or coatings to protect against corrosion and wear and tear.

In my personal experience, the type of hinge is best suited for a particular application. It will depend on a variety of factors. Including the size and weight of the door, and the frequency of use. And the conditions in which the door will be used. By carefully considering these factors and selecting a high-quality hinge that is appropriately sized and installed. It is possible to ensure maximum strength and durability for any door or gate.