As a product development engineer, I am often tasked with finding the most suitable components for our products. When it comes to designing a battery temperature test chamber, choosing the right hinge is essential. In this article, I will explore the importance of battery temperature test chamber hinges from various perspectives.

What is a Battery Temperature Test Chamber

The battery temperature test chamber is designed to test all types of batteries, including lithium-ion batteries. The battery test chamber has many safety functions built into the test chamber, which can handle battery tests and prevent safety accidents.

Charge/discharge cycle testing determines the number of times a battery can be used by evaluating it until it deteriorates after repeated cycles of charging and discharging.

What are Battery Temperature Test Chamber Hinges?

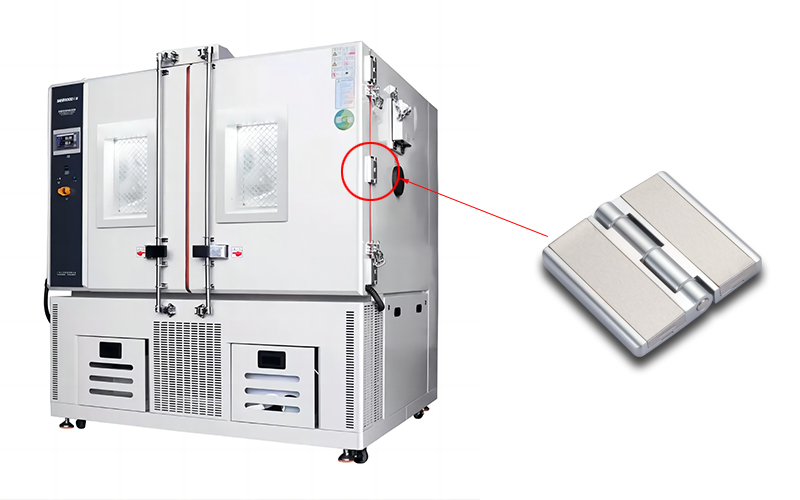

Battery temperature test chamber hinges are a type of hinge that is designed to withstand extreme temperatures. These hinges are used to attach the door of the battery temperature test chamber and ensure that it remains securely closed during the testing process.

The hinges used in a battery temperature test chamber must be able to withstand extreme temperatures. The temperature inside the chamber can range from -40°C to 150°C, and the hinges must be able to operate effectively within this range. Using hinges that are not designed to withstand these temperatures can cause the door to warp or malfunction, leading to inaccurate test results. These hinges are used on special industrial equipment and are also called industrial door hinges.

Material Selection

Choosing the right material for the hinges is critical to ensure their durability and long-lasting performance. Stainless steel is a popular choice for battery temperature test chamber hinges due to its resistance to corrosion and ability to withstand high temperatures. However, other materials such as aluminum, brass, and titanium can also be used, depending on the specific requirements of the chamber.

Design Considerations

The design of the hinges should be such that they can handle the weight of the door and remain securely attached to the chamber’s frame. The hinges should also allow for easy opening and closing of the door, without compromising on the tight seal required for temperature testing.

Maintenance

Regular maintenance of the hinges is essential to ensure their proper functioning. The hinges should be lubricated periodically to prevent rust and ensure smooth operation.

Replacement

Over time, the hinges may become worn or damaged, and they will need to be replaced. When replacing the hinges, it is essential to choose the right type of hinge. And ensure that it is installed correctly to prevent any further damage to the chamber.

Safety and Security

Battery temperature test chambers are used to test batteries under extreme conditions, and safety is of utmost importance. The hinges should be designed in such a way that they do not pose a safety hazard to the operators. Additionally, the hinges should be designed to ensure that the chamber remains securely closed during the testing process, preventing any leaks or accidents.

Compliance with Regulations

Battery temperature test chambers must comply with various regulations, such as those set by OSHA, CE, and UL. The hinges used in these chambers must meet the relevant standards and regulations to ensure their safe and effective use.

In my personal experience, the hinges used in a battery temperature test chamber are an essential component. That must be carefully selected and maintained to ensure the chamber’s proper functioning. By considering aspects such as temperature resistance, material selection, design considerations, maintenance, replacement, safety and security, and compliance with regulations. We can ensure that the hinges used in battery temperature test chambers are fit for purpose. And meet the highest standards of performance and safety.