As an industrial hinge manufacturer, I have encountered numerous inquiries about piano hinges, a type of continuous hinge commonly used in various industrial applications. While piano hinges do offer several advantages, it is essential to acknowledge their drawbacks as well. In this blog post, I will delve into the disadvantages of piano hinges, shedding light on potential issues that industrial equipment owners and engineers should consider before making a decision.

Piano hinges, while durable and reliable for industrial applications, have drawbacks including limited aesthetic appeal, restricted angle of rotation, potential misalignment issues, weight limitations, difficult repairs, noisy operation, and security concerns.

Piano Hinges – A Brief Overview

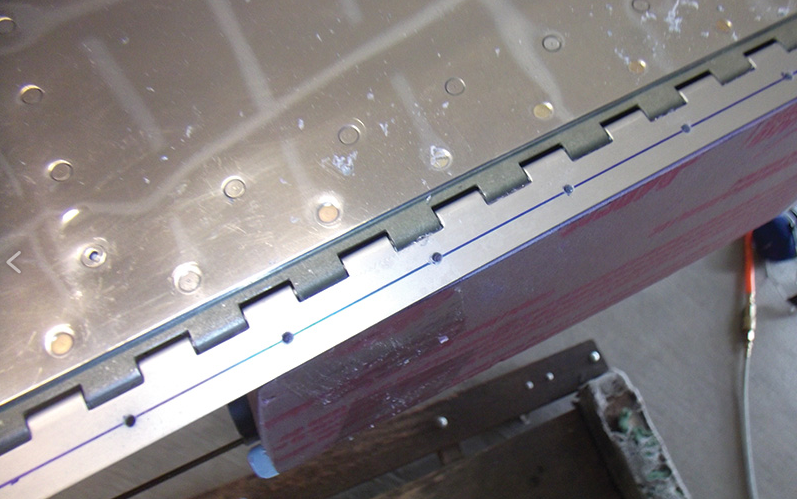

Before we delve into the drawbacks, let’s provide a concise explanation of what piano hinges are. Piano hinges, also known as continuous hinges, consist of two long plates interconnected by a pin. They extend the entire length of the objects they are attached to, enabling seamless movement along the hinge line. Due to their durable construction, they are commonly utilized in the industrial sector, particularly for the doors of industrial box equipment.

Disadvantage 1: Limited Aesthetic Appeal

While functionality is a primary concern in industrial applications, the aesthetic aspect should not be ignored. One of the notable disadvantages of piano hinges is their limited visual appeal. Unlike concealed hinges or decorative hinges, piano hinges are quite conspicuous, and their appearance might not be suitable for some projects where aesthetics play a crucial role. This limitation is especially significant if the industrial box equipment is visible to customers or clients, and its appearance matters for branding and image.

Disadvantage 2: Limited Angle of Rotation

A significant drawback of piano hinges is their limited angle of rotation. Unlike butt hinges, which allow a door to swing open up to 180 degrees, piano hinges have a fixed range of motion. The door can only open to the extent of the hinge’s length, which can be a hindrance in situations where a full 180-degree opening is necessary, such as when loading or unloading large items from the equipment.

Disadvantage 3: Potential Misalignment Issues

Ensuring precise alignment during the installation of piano hinges is critical. If the plates and the pin are not accurately aligned, it can lead to misalignment issues, causing the door or lid to bind, scrape, or not close properly. This can result in increased wear and tear on the hinge, which could eventually lead to premature failure. Proper installation techniques and attention to detail are vital to minimize the risk of misalignment.

Disadvantage 4: Weight Limitations

Piano hinges are sturdy and durable, but they do have weight limitations. Exceeding the hinge’s weight capacity can lead to problems, such as sagging doors, misalignment, and reduced overall performance. Therefore, when selecting piano hinges for industrial box equipment, it is crucial to consider the weight of the door or lid and ensure that the chosen hinge can handle the load without any issues.

Disadvantage 5: Difficult Repairs

In case of damage or wear over time, repairing piano hinges can be a more involved process compared to other types of hinges. Since piano hinges extend the entire length of the door, removing and replacing them requires extra effort and time. This could result in increased downtime for the equipment and added expenses for repairs or replacements.

Disadvantage 6: Noisy Operation

Due to their design, piano hinges can produce noise during the opening and closing of the door or lid. The metal-on-metal contact can create squeaking or creaking sounds, which might be undesirable in certain industrial environments. While lubrication can help reduce noise, it needs to be regularly maintained to ensure smooth and silent operation.

Disadvantage 7: Security Concerns

Piano hinges offer a continuous line of attachment, making it easier for unauthorized individuals to tamper with the door or lid by removing the pin or disassembling the hinge. In applications where security is a primary concern, other hinge types, such as security hinges, might be more suitable to prevent tampering and unauthorized access.

Conclusion

While piano hinges have their advantages, such as robustness and reliability, they do come with some disadvantages that industrial equipment owners and engineers should consider. Limited aesthetic appeal, restricted angle of rotation, potential misalignment issues, weight limitations, difficult repairs, noisy operation, and security concerns are all aspects to ponder upon. By understanding these drawbacks and carefully assessing the specific requirements of their projects, professionals can make informed decisions when choosing the right hinges for their industrial box equipment. At IHINGES, we believe in providing comprehensive information about hinge options to empower our clients in making the best choices for their applications.

IHINGES is a leading manufacturer of industrial hinges, specializing in durable and high-quality hinge solutions for various industrial sectors.