In the industrial manufacturing sector, hinges are more than simple connection pieces; they’re integral to the functionality and durability of various applications. Customizing these hinges requires a meticulous approach to ensure they meet specific needs and standards.

To successfully customize industrial hinges, considerations must be made for materials, loading capacities, environment compatibility, production techniques, cost, lead time, compliance, and customization flexibility. These factors collectively help in designing a hinge that fulfills the desired requirements.

Navigating these factors might seem complex, but with the right understanding and approach, it can lead to the optimal solution for your industrial needs.

What Materials Should Be Used in Industrial Hinges?

Materials selection is pivotal in industrial hinges, considering the stress and environmental conditions they must endure.

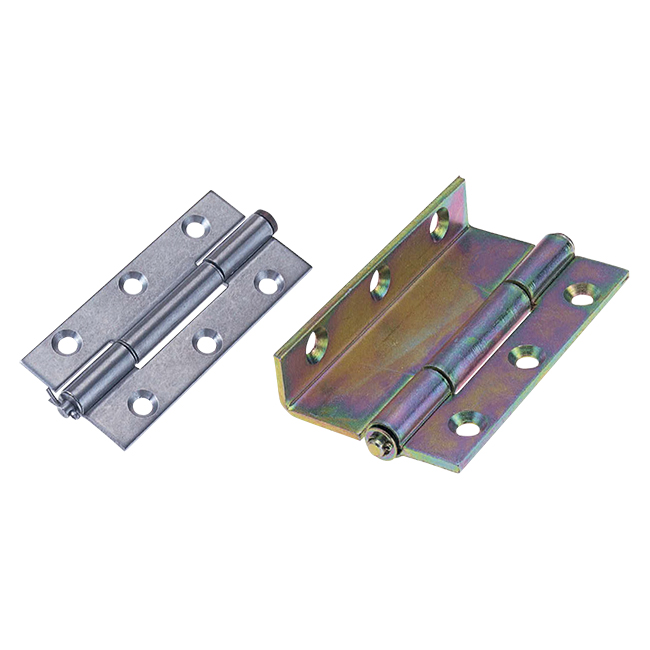

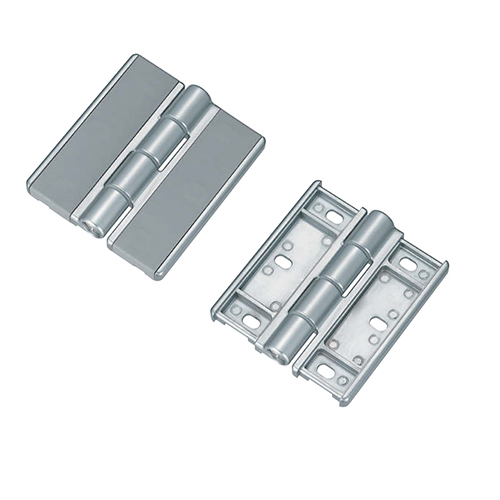

The appropriate material ensures the hinge’s robustness and longevity. Common materials like stainless steel, brass, or aluminum can be used, depending on the application’s requirements. Understanding the material’s properties, such as corrosion resistance, strength, and wear resistance, aids in making the correct choice for the hinge’s intended use.

How Should Loading Capacities Be Determined?

Loading capacity is a vital factor when customizing hinges, as it determines the ability to bear weight without failure or deformation.

Knowing the load’s nature, whether static or dynamic, and calculating the maximum load applied, are essential. Engineers must also consider factors like torque, shear stress, and tensile strength to design a hinge that performs efficiently without compromising safety and durability.

Why Is Environment Compatibility Important?

The environmental compatibility ensures the hinges function effectively in specific conditions such as temperature extremes or corrosive environments.

Selecting a hinge resistant to conditions like rust, corrosion, and extreme temperatures ensures reliability and a longer lifespan. Understanding the exact environment where the hinge will be used helps in choosing materials and coatings that withstand these particular challenges.

Which Production Techniques Should Be Utilized?

The production techniques used in manufacturing hinges greatly influence their quality and performance.

Precision machining, stamping, or forging techniques may be employed depending on the complexity and required tolerances. Selecting the right manufacturing process ensures that the customized hinge meets all specifications while maintaining efficiency and cost-effectiveness.

How to Balance Cost and Quality?

Balancing cost and quality in hinge customization requires careful consideration and planning.

Using a strategic approach that includes selecting appropriate materials, optimizing design, employing efficient production techniques, and conducting thorough quality control can result in a quality product within budget. Regular communication with suppliers and leveraging economies of scale may also contribute to cost savings without sacrificing quality.

What Lead Times Can Be Expected?

Understanding lead time is crucial for planning and optimizing the supply chain.

Considering factors such as design complexity, materials availability, production processes, and any required certifications can help estimate the lead time accurately. Keeping a transparent communication channel with the manufacturer ensures that expectations align and potential delays are mitigated.

How to Ensure Compliance with Regulations?

Compliance with industrial standards and regulations is mandatory for the safe and legal utilization of customized hinges.

Understanding the specific regulations in the industry and region and working closely with compliance teams and external bodies will ensure that the customized hinges meet all legal requirements and quality standards, thus minimizing legal risks and ensuring safety.

How to Enable Customization Flexibility?

Customization flexibility allows for modifications to meet specific requirements and future needs.

Providing options for different sizes, shapes, finishes, or other custom features makes the hinge adaptable to various applications. Collaborating with designers and engineers, and leveraging technologies like CAD design and prototyping, can facilitate this flexibility while maintaining functionality and integrity.

Conclusion

Customizing industrial hinges is a multifaceted task requiring attention to several key aspects. Understanding these eight factors will not only ensure the creation of a hinge that meets the desired specifications but also contribute to the efficiency and success of your industrial projects.

You might also be interested: