When embarking on a DIY project or making repairs, it’s natural to question whether you can modify materials to fit your needs. Piano hinges, known for their length and durability, are often considered for various applications beyond their musical origins.

However, cutting piano hinges may not always be the best approach. Customizing piano hinges directly from the manufacturer can ensure precision, durability, and functionality tailored to your specific requirements.

Engaging with this topic requires a detailed exploration of why customization is preferable over alteration, which we will delve into through various aspects.

Understanding Piano Hinges

Piano hinges, also known as continuous hinges, run the entire length of the door, lid, or panel they are attached to, offering unparalleled support and stability. These hinges are characterized by their long, narrow design, which distributes weight and stress evenly along the hinge line. This design principle is crucial in applications requiring robust performance and minimal visual interruption.

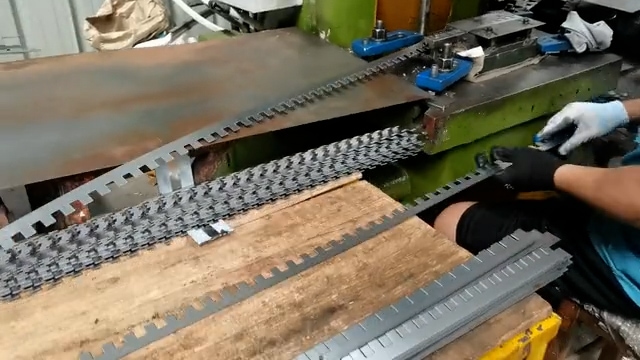

Cutting a piano hinge might seem like a straightforward solution to fitting a specific size or application. However, this process can compromise the hinge’s integrity, leading to potential malfunctions or failures. Moreover, the precision required in cutting and aligning the hinge segments can be challenging without the right tools and expertise.

The Risks of DIY Hinge Cutting

Cutting piano hinges at home introduces several risks, including imprecise cuts, weakened structural integrity, and potential safety hazards. DIY modifications can easily go awry, resulting in uneven lengths, jagged edges, or misaligned pin channels. These issues can significantly affect the hinge’s performance, leading to operational problems or even damage to the door, lid, or panel it supports.

Furthermore, cutting metal requires specific tools and safety equipment to avoid injury. Without proper experience or tools, the risk of accidents increases, posing unnecessary dangers to the DIY enthusiast.

Importance of Precision in Hinge Functionality

Precision is paramount when it comes to hinges, as even minor discrepancies can lead to misalignment, improper closure, or undue stress on the hinge or attached structures. Manufacturers use specialized equipment to ensure that each hinge meets strict tolerances, guaranteeing optimal performance and fit. This level of precision is difficult to achieve with home tools and can make a significant difference in the functionality and longevity of the hinge.

Customizing your piano hinge through a manufacturer allows for exact specifications, including length, width, material, and finish, to be met without compromising the hinge’s design and strength.

Material Considerations and Customization Options

Piano hinges are available in a variety of materials, including steel, brass, and stainless steel, each offering different properties in terms of strength, corrosion resistance, and appearance. Choosing the right material is crucial for the hinge to perform correctly in its intended environment. Cutting a hinge not only affects its physical integrity but can also expose untreated edges to corrosion or wear.

By customizing hinges through a manufacturer, you can select the appropriate material for your specific application, ensuring longevity and functionality. Additionally, manufacturers can provide finishes that match or complement the surrounding hardware or decor, enhancing aesthetic appeal.

The Role of Professional Expertise

Manufacturers possess extensive knowledge and experience in designing and producing piano hinges for various applications. This expertise allows them to advise on the best configurations for your specific needs, taking into account factors such as load-bearing capacity, environmental conditions, and frequency of use. Cutting a piano hinge without this expertise can lead to poor performance and potentially costly mistakes.

Consulting with professionals ensures that you receive a hinge that is perfectly suited to your application, without the risks associated with DIY modifications.

Cost-Effectiveness and Long-Term Value

While cutting a piano hinge might seem cost-effective initially, it can lead to additional expenses in the long run. Mistakes in cutting or installation can necessitate the purchase of replacement hinges or even repairs to the attached structures. Customizing hinges through a manufacturer might have a higher upfront cost but offers greater value over time through durability and reliability.

Investing in a customized solution ensures that your hinge is a one-time purchase that meets your needs without the need for adjustments or replacements.

Environmental and Sustainability Considerations

Cutting piano hinges can lead to waste, especially if errors occur during the process. Customization minimizes waste by producing hinges that fit the application perfectly from the outset. Additionally, manufacturers often have recycling programs for metal offcuts, contributing to more sustainable production practices.

Choosing a customized hinge supports environmental sustainability by reducing waste and promoting efficient use of resources.

Conclusion

Although it might be tempting to cut piano hinges to fit specific requirements, the potential drawbacks make it clear that customization through the manufacturer is the superior choice. This approach ensures precision, functionality, and aesthetic appeal while avoiding the risks and limitations of DIY modifications. When considering piano hinges for your next project, remember that professional customization offers the best solution for a seamless, reliable, and sustainable outcome.

You may be interested:

- What’s the Best Hinges For Heavy Doors?

- 6 Things You Must Know About Small Piano Hinges

- The 7 Most Popular Topics About Quadrant Hinges

- 9 Things You Must Know Before Purchasing 5-Inch Hinges