You might think a hinge is just a hinge. However, when it comes to boat hatch hinges, the waters get a bit more turbulent. Boat hatch hinges form a crucial part of marine equipment, ensuring that your vessel’s access points function seamlessly and safely. As manufacturers in the marine industry, we know that not all hinges are created equal. Selecting the right hinge is integral to the vessel’s performance and the safety of its crew.

From their material to their design, boat hatch hinges are a product of both ingenuity and purpose. Whether you’re dealing with extreme weather conditions or regular wear and tear, these hinges need to perform reliably. In this post, we will discuss eight different types of boat hatch hinges that are utilized in the marine industry and shed light on their unique features and applications.

Let’s embark on this journey of understanding how something as seemingly simple as a hinge can have so many variations, each serving a crucial purpose in marine environments. Dive in!

Strap Hinges

Strap hinges are quite versatile and are characterized by their long, narrow design. These hinges can be quite durable, making them suitable for heavier hatches on marine vessels. Strap hinges offer an ideal balance of strength and flexibility, which are key factors for maritime conditions.

Materials used for strap hinges often include stainless steel or brass, known for their corrosion-resistant properties. The choice of material and the hinge’s design contribute to its durability and long-lasting performance in saltwater conditions.

Butt Hinges

Butt hinges are a common type of hinge seen in various applications, and boat hatches are no exception. They are sturdy and reliable, with two leaves that meet in the middle, connected by a pin. This design allows for easy installation and removal, which is particularly beneficial in a marine setting.

While they might be simple in design, butt hinges are incredibly robust. They can be made from corrosion-resistant materials such as stainless steel or brass, ensuring a long lifespan even in harsh marine environments.

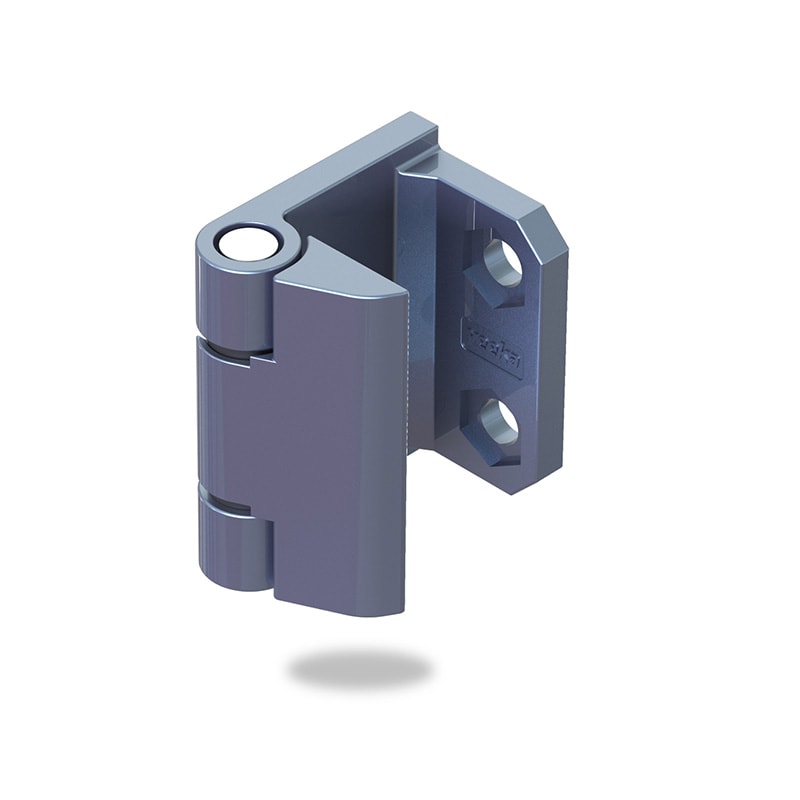

Offset Hinges

Offset hinges are specially designed to allow a hatch to swing clear of the frame and lie flat when opened. This feature can be quite beneficial on a boat where space is often limited, and the full utilization of available space is critical.

These hinges are built to be sturdy and reliable. Depending on the specific needs of your boat hatch, offset hinges made of marine-grade materials can offer enhanced resistance to the corrosive marine environment while ensuring smooth operation.

Piano Hinges

Piano hinges, also known as continuous hinges, run the entire length of the hatch. This design allows for the weight to be distributed evenly across the hinge, providing enhanced stability and strength. It’s particularly beneficial for larger hatches.

Crafted from marine-grade materials such as stainless steel or aluminum, piano hinges can withstand the wear and tear of the marine environment. Their durability, combined with their ability to provide a smooth and consistent operation, makes them a popular choice for boat hatches.

European Hinges

European hinges, often used in cabinetry, have also found a place in marine applications. Their concealed design offers a clean and streamlined look, contributing to the aesthetic appeal of the boat. Additionally, their adjustability allows for precise alignment of the hatch.

Manufactured from materials such as stainless steel, European hinges bring together style and functionality. They are designed to withstand the harsh marine environment while ensuring smooth operation and enhancing the overall appearance of the boat.

Take-Apart Hinges

Take-apart hinges, as their name suggests, are designed to be easily taken apart. This feature is useful in marine settings where hatches may need to be removed for maintenance, cleaning, or during emergencies.

Like all marine hardware, these hinges are also made from materials like stainless steel that can resist the corrosive effects of saltwater and weather. Their unique design coupled with durability makes them a valuable addition to boat hatches.

Friction Hinges

Friction hinges are designed to hold the hatch open in any position, preventing it from slamming shut due to wind or the motion of the boat. This feature enhances safety on the boat, a crucial factor in marine environments.

Friction hinges need to be robust and reliable, characteristics achieved by using corrosion-resistant materials like stainless steel or brass. They offer an improved user experience by providing better control over the hatch’s movement and position.

Concealed Hinges

Concealed hinges, as the name suggests, are hidden when the hatch is closed, contributing to a sleek and seamless look. These hinges are often adjustable, allowing for perfect alignment of the hatch.

Being made from materials like stainless steel ensures that they can withstand the harsh marine environment while providing reliable performance. Their ability to combine aesthetics with function makes them a popular choice for modern boat designs.

Conclusion

Boat hatch hinges may be small components, but their impact on the performance and safety of a marine vessel is substantial. From strap hinges to concealed hinges, each type comes with its unique features and benefits. By understanding these different hinges and their respective advantages, you can make informed decisions that enhance both the functionality and aesthetics of your marine vessel.

You might also be interested: