In our everyday lives, we might not think too much about hinges, but if you stop and look around, you’ll realize just how prevalent they are. As an integral part of various mechanical systems in the industrial manufacturing sector, hinges play a critical role. But what happens when you’re presented with a choice? Ball bearing hinges or regular hinges – which one should you opt for in your manufacturing processes? I, like many, have found myself pondering this question.

When it comes to industrial manufacturing, ball bearing hinges have the edge over their regular counterparts. Why is this so? The reason lies in their superior strength, durability, smoother operation, and minimal maintenance requirements. But it’s not just about these advantages; the choice between these two types of hinges depends largely on the specific requirements of your industrial application.

Let’s embark on this journey to dive deeper into the world of hinges, their role in industrial manufacturing, and why ball bearing hinges might just be the better choice for your operations.

What Makes a Hinge ‘Regular’?

The term ‘regular hinge’, often known as a butt hinge, refers to the most common type of hinge design you’ll come across. These hinges consist of two leaf plates with a pin going through their aligned knuckles.

Regular hinges have been widely used in various applications due to their simple design and ease of installation. However, in the world of industrial manufacturing, this simplicity can sometimes lead to limitations. For instance, under heavy load and frequent usage, regular hinges might wear out faster, leading to more maintenance downtime and cost.

How Do Ball Bearing Hinges Differ?

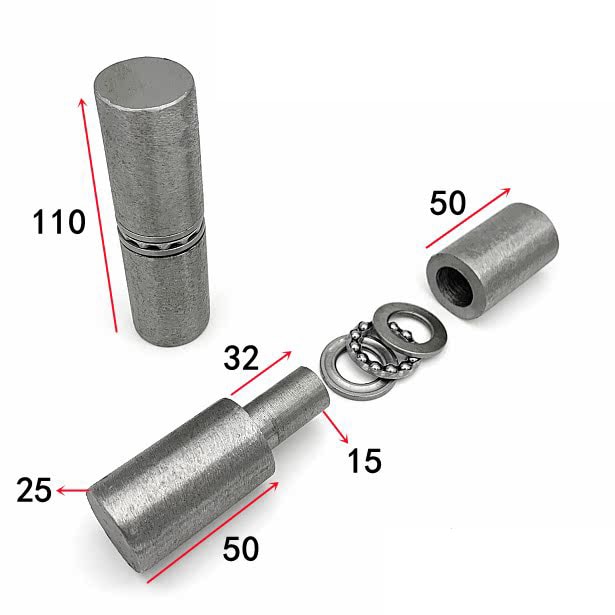

Ball bearing hinges, as their name suggests, incorporate tiny ball bearings within their knuckles. These ball bearings act as a buffer between the metal surfaces, reducing friction during operation.

The use of ball bearings drastically reduces the wear and tear on the hinge, resulting in a smoother swing, a quieter operation, and an extended lifespan. This longevity is a significant factor to consider in industrial manufacturing, where every minute of downtime can translate into substantial financial loss.

Are Ball Bearing Hinges More Durable?

Ball bearing hinges are renowned for their durability. Thanks to the ball bearings, the friction between the hinge leaves is significantly reduced, leading to less wear and tear.

This high durability makes them an excellent choice for industrial applications involving heavy machinery or equipment. When it comes to bearing high loads and providing smooth, silent operation over long periods, ball bearing hinges are simply unmatched.

Do Ball Bearing Hinges Require Less Maintenance?

When it comes to maintenance, ball bearing hinges again take the lead. Their design, incorporating ball bearings, minimizes friction and wear, which translates to less maintenance over their lifespan.

In the industrial manufacturing world, maintenance translates to downtime, and downtime equals lost productivity and profits. Thus, by choosing ball bearing hinges, industries can achieve a more efficient and cost-effective production process.

Can Ball Bearing Hinges Handle More Weight?

With their design and structure, ball bearing hinges are better equipped to handle higher weights compared to regular hinges. The bearings within the hinge distribute the weight more evenly, leading to smoother operation even under substantial loads.

For industries manufacturing heavy machinery or products, this weight-bearing capability of ball bearing hinges is invaluable. It ensures the seamless operation of the equipment, minimizing any potential disruptions in the production process.

Are Ball Bearing Hinges Worth the Extra Cost?

While ball bearing hinges generally cost more than regular hinges, it’s crucial to consider the long-term benefits. Yes, the initial investment may be higher, but the lower maintenance cost, longer lifespan, and higher durability often justify the added expense.

When operating in the industrial manufacturing sector, it’s often about the bigger picture. A strategic decision like choosing ball bearing hinges can make a noticeable difference in operational efficiency, cost savings, and product lifespan, providing a higher return on investment over time.

Conclusion

When it comes to industrial manufacturing, ball bearing hinges seem to have a definite edge over regular hinges. Their superior durability, lower maintenance needs, and better weight-handling capability can contribute significantly to operational efficiency and cost-effectiveness. While the initial investment might be higher, the long-term benefits and potential savings often justify the choice. After all, when it comes to industrial manufacturing, every detail matters – and that includes the humble hinge.

You might also be interested: