When navigating the intricate pathways of industrial manufacturing, the importance of minor components can be easily overlooked. Among these, hinges play a pivotal role, ensuring smooth operations and long-lasting performance. But how does one choose between ball bearing hinges and plain bearing hinges?

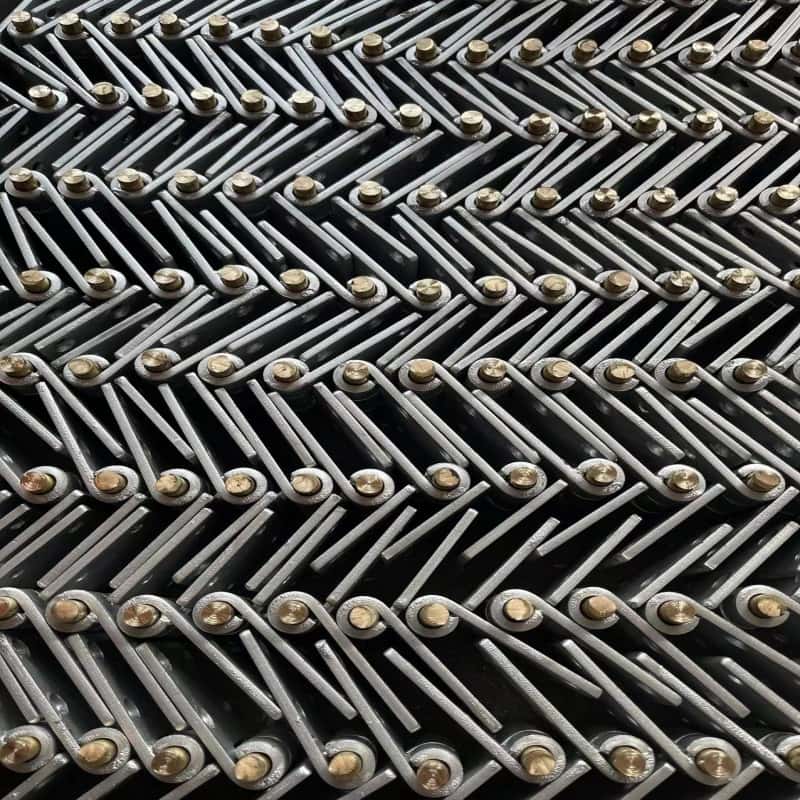

At a glance, ball bearing hinges utilize small ball bearings to reduce friction, ensuring smoother operation, while plain bearing hinges rely on two surfaces sliding against each other without any rolling intermediary.

Such a distinction might seem subtle but can significantly impact the efficiency and longevity of your machinery.

How do these Hinges Function in the Industrial Sector?

Every piece of machinery demands precision. In our vast industrial landscape, hinges are essential for ensuring movement without wear. The way ball bearing and plain bearing hinges function is fundamentally different.

For ball bearing hinges, the inclusion of ball bearings between the knuckles reduces friction. These ball bearings act as a buffer, preventing the metal parts from grinding against each other, ensuring smoother motion. On the other hand, plain bearing hinges rely on direct metal-to-metal contact. Here, the two metal surfaces slide against each other, and their functionality depends heavily on the quality and smoothness of these surfaces.

What Drives the Choice Between the Two?

Industrial manufacturing is a world of choices. Each decision affects efficiency, productivity, and, ultimately, the bottom line. So, when choosing between ball bearing and plain bearing hinges, what factors come into play?

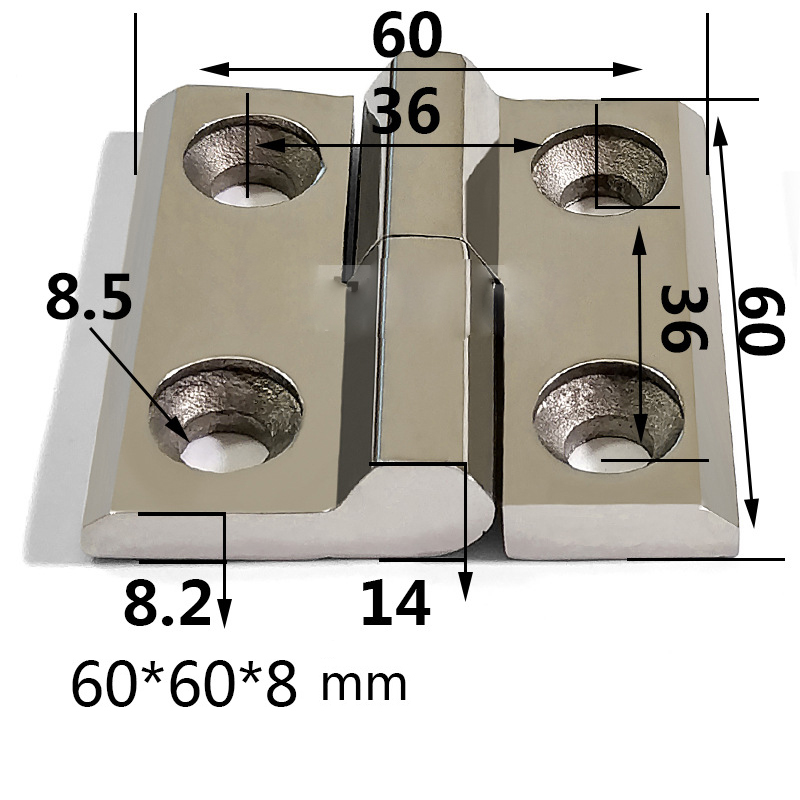

Ball bearing hinges are ideal for applications that require frequent use or heavier loads. Their design minimizes wear, thus increasing their lifespan. Conversely, plain bearing hinges are simpler in construction and often more affordable. However, they might wear out faster in heavy-duty applications due to the direct metal-to-metal contact.

Efficiency: Which Hinge Offers Better Performance?

Performance is paramount in industrial manufacturing. Even minute inefficiencies can lead to significant losses over time. So, between ball bearing and plain bearing hinges, which offers superior performance?

Ball bearing hinges, due to their reduced friction, provide smoother operation. This results in less wear and increased longevity, especially in high-frequency operations. On the flip side, plain bearing hinges can work efficiently, but their performance is tied to the quality of their construction. Any inconsistencies in their build can lead to increased friction and faster wear.

Durability: Which Hinge Lasts Longer?

Longevity is a crucial consideration. The longer our machinery lasts, the better our ROI. So, when it comes to durability, how do these hinges compare?

With ball bearing hinges, the bearings act as a protective buffer, minimizing wear. This often translates to a longer lifespan, especially under heavy use. However, plain bearing hinges, due to their simpler design, have fewer parts that could potentially fail. But their direct metal-to-metal contact can lead to faster wear, depending on usage and environmental factors.

Maintenance: Is One Easier to Upkeep?

Every machine requires care. And maintenance plays a key role in ensuring the longevity and efficiency of our equipment. But between these hinges, is one easier to maintain?

Ball bearing hinges, while durable, might require occasional lubrication to keep the bearings functioning optimally. Over time, these bearings can wear out and may need replacement. Plain bearing hinges, on the other hand, have a straightforward design. Their maintenance mainly involves ensuring that the hinge surfaces remain clean and free from debris, preventing undue friction.

Cost Implications: Which is More Economical?

Budgeting is a core aspect of industrial operations. Every component’s cost can influence the broader financial landscape. So, when deciding between ball bearing and plain bearing hinges, how does cost come into the picture?

Typically, ball bearing hinges tend to be more expensive due to their intricate design and the inclusion of bearings. However, their durability can sometimes justify the higher upfront cost. Plain bearing hinges are usually more budget-friendly, but their potential for faster wear in certain applications might lead to increased replacement costs in the long run.

Potential Drawbacks: Are There Any Limitations?

Every tool or component has its limitations. Recognizing these can help in making informed decisions. So, what potential drawbacks should we be aware of?

While ball bearing hinges offer smooth operation, they might be overkill for applications that don’t require frequent use. Also, if not maintained, the ball bearings can degrade over time. As for plain bearing hinges, their direct metal contact means they might not be suitable for high-frequency or heavy-duty applications, as this can accelerate wear.

Conclusion

In the intricate dance of industrial manufacturing, choosing between ball bearing and plain bearing hinges boils down to understanding specific requirements. Both have their strengths and limitations. While ball bearing hinges offer smoother performance and durability, plain bearing hinges provide simplicity and cost-effectiveness. It’s all about striking the right balance to ensure efficiency, longevity, and optimal ROI.

You might also be interested: