Choosing the right hinge for industrial applications requires careful consideration of strength and durability. Aluminum butt hinges are often a popular choice, but are they strong enough?

Aluminum butt hinges are strong and durable, offering an excellent strength-to-weight ratio. They perform well in industrial applications, especially where lightweight, corrosion-resistant solutions are required.

Dive deeper to understand why aluminum butt hinges are a reliable choice for demanding applications.

Understanding Aluminum Butt Hinges

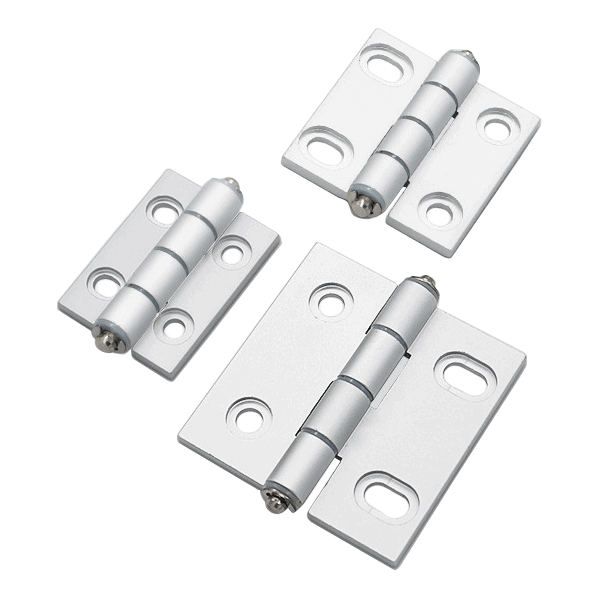

Aluminum butt hinges are versatile hardware designed for a wide range of applications, from industrial equipment to commercial enclosures. Made of lightweight aluminum, they are easy to install and provide excellent functionality.

The inherent properties of aluminum make these hinges corrosion-resistant and durable. Unlike heavier materials like steel, aluminum reduces the overall load on structures, making it ideal for projects where weight matters, such as trailer door hinges and marine hinges.

What are Aluminum Butt Hinges?

Aluminum butt hinges are composed of two interlocking plates connected by a pin, allowing rotation. This simple yet robust design ensures reliable performance in various industrial applications.

| Feature | Benefit |

|---|---|

| Lightweight | Reduces overall structure weight |

| Corrosion-resistant | Suitable for harsh environments |

| Durable design | Withstands repeated use |

Strength and Durability of Aluminum Butt Hinges

Aluminum has a remarkable strength-to-weight ratio, making it a dependable material for hinges used in demanding environments. It resists stress and wear while maintaining functionality over time.

Durability depends on the hinge’s design, grade of aluminum, and environment. High-quality aluminum alloys are particularly resistant to deformation and corrosion, ensuring long-term reliability in applications such as cold storage room hinges or climatic test chamber hinges.

How Strong Are They?

Aluminum butt hinges are robust enough to handle moderate to heavy loads, depending on the specific design. Properly installed, they can endure harsh conditions without compromising performance.

Advantages of Aluminum Butt Hinges

Aluminum butt hinges offer numerous advantages for industrial and commercial use. Their lightweight construction ensures ease of use without sacrificing durability, while their resistance to rust makes them ideal for outdoor or moisture-prone settings.

Corrosion resistance is particularly beneficial for industries requiring long-lasting hardware, such as the marine and refrigeration sectors. Additionally, their cost-effectiveness makes aluminum butt hinges a go-to option for large-scale projects.

Why Choose Aluminum Butt Hinges?

- Cost Efficiency: Affordable without compromising quality.

- Environmental Resistance: Performs well in diverse climates.

- Versatility: Used in a variety of industries, from weld on hinges in heavy machinery to decorative applications in commercial settings.

Applications and Suitability

Aluminum butt hinges are widely used across industries, including automotive, marine, and industrial manufacturing. They are especially effective in applications requiring corrosion resistance and lightweight hardware.

For instance, they are the preferred choice for industrial hinge production bases focusing on mass manufacturing or customized designs for unique projects. Their adaptability makes them suitable for standard and heavy-duty uses alike.

Ideal Industrial Applications

- Marine Equipment: Aluminum’s corrosion resistance is perfect for saltwater environments.

- Cold Storage Facilities: Suitable for maintaining integrity in temperature-sensitive environments.

- Industrial Doors: Lightweight yet durable for frequent use in warehouses or factories.

Tips for Choosing Aluminum Butt Hinges

To select the right aluminum butt hinges for your project, consider factors such as load capacity, environmental conditions, and the specific requirements of your application.

For example, heavy duty hinges are better for high-stress environments, while soft close hinges are ideal for precision equipment that demands quiet operation. Always consult with hinge experts for tailored recommendations.

| Consideration | Why It Matters |

|---|---|

| Load Capacity | Ensures durability under stress |

| Corrosion Resistance | Extends lifespan in harsh climates |

| Customization Options | Fits specific project needs |

Conclusion

Aluminum butt hinges are a reliable and durable choice for industrial applications. Their lightweight, corrosion-resistant properties make them suitable for diverse environments, proving their worth in even the most demanding conditions.