Anodized aluminum and regular aluminum are commonly used in manufacturing, cookware, and industrial applications. Understanding their differences can help determine which is better for specific purposes.

Anodized aluminum is more durable, corrosion-resistant, and safer than regular aluminum, making it ideal for cookware, construction, and industrial uses.

Curious about the benefits of anodized aluminum over untreated options? Let’s explore their differences, strengths, and limitations in detail.

What is Anodized Aluminum and Regular Aluminum?

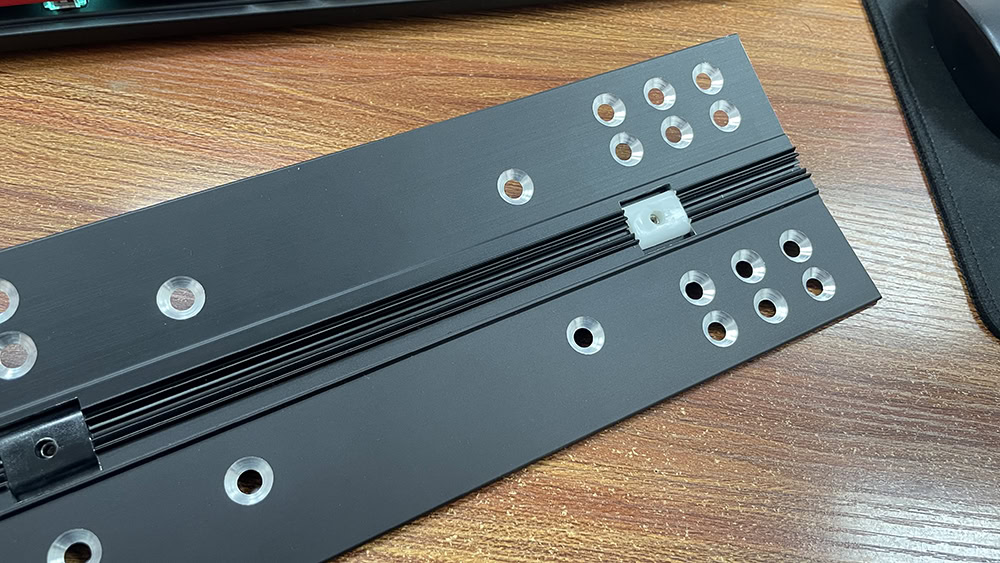

Anodized aluminum is regular aluminum that has undergone an electrochemical process to create a thicker, protective oxide layer on its surface. This enhances its durability and corrosion resistance. Regular aluminum, on the other hand, remains untreated and lacks this protective layer.

Anodized aluminum has a protective oxide layer that improves corrosion resistance and durability, while regular aluminum is untreated and prone to oxidation.

Anodizing transforms the naturally soft aluminum surface into a hardened, scratch-resistant material. This process is widely used for aluminum hinges, cookware, and aerospace components.

Key Differences Between Anodized and Regular Aluminum

Regular aluminum is lightweight, affordable, and widely used but lacks surface durability. Anodized aluminum is far superior in resisting scratches, corrosion, and wear.

Key differences:

- Surface Hardness: Anodized aluminum is much harder and scratch-resistant.

- Corrosion Resistance: The anodized layer protects against rust and chemical damage.

- Appearance: Anodized aluminum has a sleek, decorative finish compared to raw aluminum’s dull surface.

For industries producing climatic test chamber hinges and aerospace materials, anodized aluminum is often preferred due to its superior resilience.

Strength and Durability of Anodized Aluminum

Anodized aluminum features significantly improved surface hardness. While anodizing does not alter the core strength of aluminum, the oxide layer enhances surface resistance to damage.

Anodized aluminum’s surface is harder and more durable than untreated aluminum, offering a longer lifespan in harsh conditions.

For heavy-use applications, such as marine hinges and structural components, anodized aluminum resists wear and tear far better than untreated options. Properly anodized aluminum can last decades with minimal maintenance, making it a cost-effective choice over time.

Corrosion Resistance of Anodized Aluminum

One of the greatest advantages of anodized aluminum is its exceptional corrosion resistance. The anodized oxide layer acts as a protective barrier against moisture, chemicals, and environmental exposure.

Anodized aluminum resists corrosion far better than untreated aluminum, ensuring superior performance in harsh environments.

Industries like marine manufacturing and construction rely on anodized aluminum to prevent rust in damp or saline conditions. Applications requiring trailer door hinges or outdoor structures benefit immensely from anodizing, as regular aluminum oxidizes and corrodes quickly in similar environments.

Is Anodized Aluminum Safe?

Anodized aluminum cookware is popular due to its safety and non-reactive properties. Unlike untreated aluminum, anodized surfaces do not leach metal into food, even when exposed to acidic ingredients.

Anodized aluminum is safe for cookware, as it is non-reactive and poses no health risks, unlike untreated aluminum.

Non-anodized aluminum cookware, by contrast, can pose health concerns. The anodizing process seals the surface, making anodized aluminum the safer choice for long-term kitchen use.

Anodized Aluminum vs. Stainless Steel

Choosing between anodized aluminum and stainless steel depends on the application.

- Weight: Anodized aluminum is lighter, making it easier to handle and install.

- Heat Conductivity: Aluminum, including anodized types, conducts heat better than stainless steel.

- Durability: While stainless steel is harder overall, anodized aluminum offers excellent scratch resistance.

Anodized aluminum is lighter, more conductive, and less expensive, while stainless steel excels in scratch resistance and durability.

For industries requiring lightweight solutions, such as aluminum geared continuous hinges, anodized aluminum strikes the right balance between performance and cost.

What Happens if Aluminum is Not Anodized?

If aluminum is left untreated, it will naturally oxidize, forming a thin, fragile layer of aluminum oxide. This layer lacks durability and can flake off over time.

Non-anodized aluminum corrodes, scratches easily, and develops unsightly oxidation marks over time.

Without anodizing, aluminum components—like industrial parts or piano hinges—are prone to pitting, corrosion, and structural weaknesses, significantly reducing their lifespan.

Limitations and Downsides of Anodized Aluminum

While anodized aluminum offers numerous benefits, it has some limitations:

- Cost: Anodizing increases the material cost compared to untreated aluminum.

- Heat Sensitivity: Excessive heat can damage the anodized layer.

- Chemical Damage: Harsh chemicals may compromise the anodized surface if not properly maintained.

Anodized aluminum costs more and can be damaged by extreme heat or chemicals, requiring careful use and maintenance.

Despite these downsides, its benefits often outweigh the limitations, especially for long-term applications.

Is Anodized Aluminum Worth the Cost?

The higher cost of anodized aluminum is justified by its superior durability, corrosion resistance, and aesthetics. For industries requiring long-lasting performance—such as aerospace, marine, and industrial manufacturing—anodized aluminum proves invaluable.

Anodized aluminum offers excellent value, as its durability and performance outweigh the higher upfront cost for most applications.

For businesses producing special hinges or components exposed to harsh environments, anodized aluminum remains the preferred choice due to its long-term benefits.

Conclusion

Anodized aluminum is undoubtedly better than regular aluminum in terms of durability, safety, and corrosion resistance. While it costs more initially, its longevity and superior performance make it an ideal material for cookware, industrial applications, and construction needs.