Bare metal exposed to moisture can rust quickly, often within minutes under the right conditions. Knowing how and why this happens helps in selecting effective rust prevention methods for different environments.

Bare metal can start rusting within minutes after getting wet depending on factors like humidity, temperature, and metal type. Flash rust, an initial surface corrosion, often forms within 30 minutes in moist environments. To prevent this, coatings, rust inhibitors, and desiccants are essential for exposed bare metals.

Various factors affect how quickly bare metal rusts when wet. Let’s explore them below.

What Is Flash Rusting and Why Does It Happen?

When bare metal gets wet, flash rusting can create a visible layer of corrosion almost immediately.

Flash rusting is a rapid corrosion process on bare metal surfaces that can begin within minutes or hours when exposed to water, especially in humid or salty environments. This initial rust layer spreads quickly if left untreated, impacting metal surfaces.

Flash rusting is common on carbon steel and similar metals when moisture and oxygen interact on the surface. In humid or coastal areas, this process speeds up due to the presence of salt. Though flash rust is usually superficial, leaving it untreated can cause deeper corrosion, weakening the metal over time.

Factors Influencing Flash Rust Speed

| Factor | Impact |

|---|---|

| Humidity Levels | Higher humidity accelerates rust |

| Temperature | Warm conditions speed up reactions |

| Salt Presence | Saltwater or air increases rusting |

Environmental Factors That Affect Rust Formation Time

Environmental factors like humidity, temperature, and salt exposure can impact rusting speed on bare metals.

The time it takes for rust to form on bare metal after exposure to water varies with environmental conditions. High humidity and warm temperatures can cause rust to form within minutes to hours.

Rust forms faster in humid, coastal areas. When metals are left outside without a protective layer, frequent exposure to rain, fog, and moisture accelerates oxidation. Indoor environments can slow down rusting, although high humidity still poses risks. Temperature also plays a role, with warmer weather speeding up rusting and cold conditions slowing it down.

Differences in Rusting Between Metal Types: Steel vs. Aluminum

Steel and aluminum react differently to wet conditions, impacting rust speed.

Steel can rust within hours when exposed to water, especially in humid environments, while aluminum generally resists rusting but corrodes in specific conditions, such as saltwater exposure.

Carbon steel and iron are highly reactive with oxygen and water, making them prone to rust when exposed to moisture. Aluminum, by contrast, does not rust but forms an oxide layer that resists further corrosion. However, in highly saline environments, even aluminum can corrode. These differences highlight why steel needs more protective coatings in damp conditions, while aluminum is generally more corrosion-resistant but still not completely immune.

Why Rust Can Appear Almost Overnight on Bare Metal

Bare metal can rust very quickly, especially under certain environmental conditions.

In humid or salty areas, rust can form on bare metal within 24 hours, or even sooner if flash rust conditions are present. Protective coatings are essential to prevent rapid corrosion on exposed metal surfaces.

Bare metal surfaces in humid, rainy, or salty environments often show rust within a day. This is especially common in coastal regions or during rainy seasons. The reaction between water and oxygen on the metal’s surface speeds up the rusting process, particularly without protective coatings. Flash rust may even appear overnight on metal tools left outside.

How Long Does Bare Steel Last Outside Without Protection?

Bare steel left outside can quickly deteriorate without protective measures.

Bare steel can begin degrading within days to weeks if exposed to outdoor elements without protection, depending on factors like rainfall, humidity, and temperature. For long-term outdoor use, protective coatings or treatments are essential to ensure steel durability.

Unprotected steel can develop surface rust within hours or days in moist conditions, with further corrosion developing over weeks. Regular exposure to rain and sunlight speeds up rusting, eventually affecting the structural integrity of the metal. Coatings, galvanization, or painting are recommended to extend outdoor steel’s lifespan.

Rusting of Bare Metal Underwater: How Fast Does It Occur?

The rate of rusting underwater depends on water type, with saltwater accelerating the process.

Rusting underwater occurs more slowly in freshwater than saltwater. Steel rusts faster in saltwater because of high chloride content, which facilitates electrochemical reactions on metal surfaces.

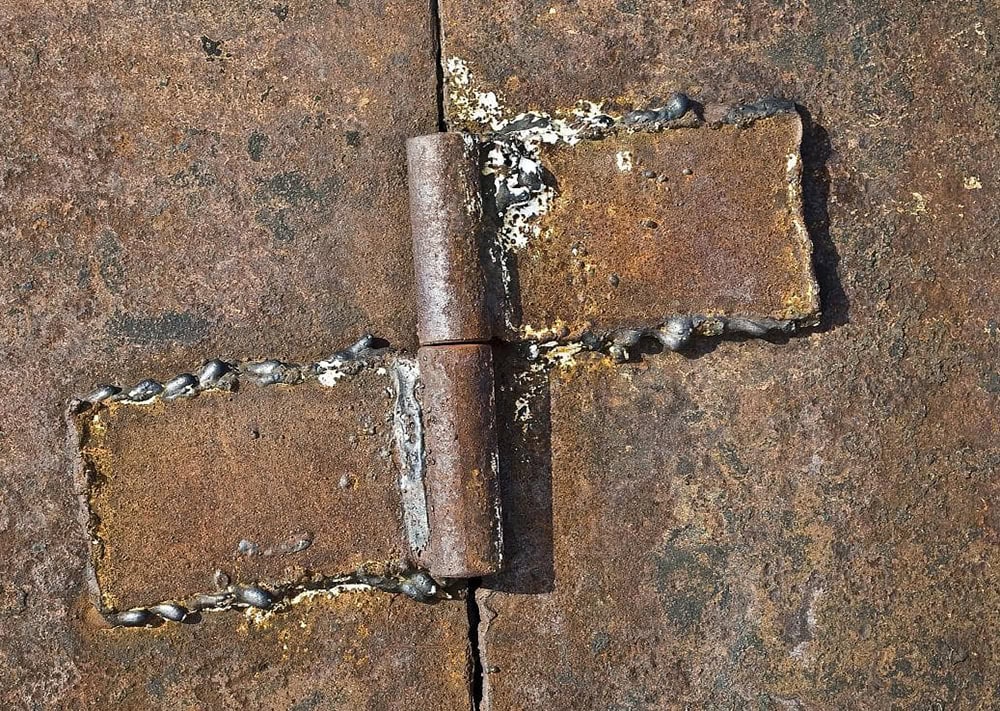

Freshwater submersion slows down rusting compared to saltwater. Chlorides in saltwater promote faster electrochemical reactions that accelerate rust on metals like steel. While aluminum can better resist corrosion underwater, steel left submerged in saltwater may corrode extensively within weeks. Coastal and marine environments pose greater risks for unprotected metals, often requiring durable coatings or specialized marine hinges for added protection.

Ways to Prevent Rust on Bare Metal Surfaces

Preventing rust requires a combination of protective coatings and controlled environments.

Applying protective coatings, reducing moisture exposure, and regular cleaning are effective ways to prevent rust on bare metal surfaces. These measures are critical in humid or marine environments.

Effective rust prevention includes using paint, primer, or rust-inhibiting coatings on bare metal. Reducing moisture exposure and storing metals in dry areas are additional strategies to extend metal life. Regular cleaning to remove salt or moisture buildup is also helpful in humid or salty environments. Without these protective steps, bare metals are more likely to rust quickly, especially if left outdoors.

Indoor vs. Outdoor Rusting Rates for Bare Metal

Rusting rates differ between indoor and outdoor environments, with outdoor exposure accelerating the process.

Rusting happens slower indoors due to limited exposure to environmental elements, while outdoor conditions increase rusting speed from direct contact with rain and humidity.

Indoor environments with controlled humidity slow down rust formation on bare metals. However, even indoors, high humidity or occasional water exposure can lead to rust. Outdoor environments, with exposure to fluctuating humidity, rain, and sunlight, cause rusting to accelerate. Therefore, protective measures are more essential for metals used or stored outside, especially in high-rust environments.

Comparing Rust Formation on Carbon Steel and Stainless Steel

Carbon steel and stainless steel corrode at different rates, with stainless steel offering better resistance.

Carbon steel rusts quickly when wet, while stainless steel resists rust due to its chromium content, though it can corrode under extreme conditions.

Carbon steel’s high iron content makes it especially prone to rust. Stainless steel, by contrast, contains chromium, which forms a passive oxide layer resistant to rust. Prolonged exposure to saltwater or acidic environments, however, can compromise this protective layer. Stainless steel is ideal for damp conditions but still requires maintenance in high-salt areas, making it an excellent choice for applications like butt hinges in marine settings.

Why Aluminum Doesn’t “Rust” Like Other Metals

Aluminum does not rust in the traditional sense; it develops a protective oxide layer.

Aluminum resists rusting due to an oxide layer that forms naturally, which protects it from further corrosion, unlike the continuous rusting seen in carbon steel.

Aluminum develops a thin, protective oxide layer when exposed to oxygen, preventing further corrosion. However, this oxide layer can break down in high-salt or acidic environments, causing localized corrosion. Unlike iron-based metals, aluminum does not undergo continuous rusting, making it suitable for marine and outdoor applications, including aluminum hinges for high-durability needs.

Conclusion

Understanding how bare metal rusts when wet helps in choosing suitable preventive measures. By using protective coatings and selecting corrosion-resistant materials, rusting can be effectively minimized, even in challenging environments.