Flush hinges may seem appealing due to their minimalistic design, but they come with significant limitations that impact durability and functionality, particularly in industrial settings. These disadvantages can hinder performance in applications where strength and load-bearing are critical, making it essential to understand their drawbacks.

Flush hinges have notable disadvantages, including limited load-bearing capacity, difficulty with precise installation, and reduced durability under frequent use. They may not suit heavy-duty applications or high-traffic areas.

Learn about key drawbacks of flush hinges before deciding if they suit your project needs.

Limited Load-Bearing Capacity

Flush hinges are designed for light doors and panels, which limits their suitability in high-load or industrial applications. Because of their smaller structure and installation style, they often fail under substantial weight, which can lead to misalignments or even hinge failure. This makes flush hinges less effective in environments that require robust support, such as for Heavy Duty Hinges.

For companies needing reliable hinges for weight-bearing doors or larger panels, this limitation necessitates either frequent hinge replacements or alternative solutions like butt hinges or piano hinges.

Reduced Durability in High-Traffic Areas

Since flush hinges have minimal structure, they tend to wear down faster when used on doors or cabinets that are frequently opened and closed. This is particularly disadvantageous for high-traffic commercial areas, where frequent use can quickly degrade the hinge’s functionality and aesthetic appearance.

This issue can lead to constant repairs and replacements, reducing the overall lifespan of flush hinges in business environments that require resilience. Alternatives like concealed hinges or aluminum hinges often perform better in these settings due to their reinforced designs.

Installation Challenges

Flush hinges require precise alignment during installation, which can be complex and time-consuming, especially on large-scale projects or for doors with precise functionality needs. Even slight misalignments can result in sticking or uneven doors, necessitating repeated adjustments that impact productivity and increase labor costs.

In comparison, other hinges such as Cold Storage Room Hinges and butt hinges offer more installation flexibility and can reduce time spent on alignment, making them better suited for industrial applications.

Limited Aesthetic Flexibility

Flush hinges are often limited in aesthetic options, which can hinder customization efforts for businesses with specific branding or design requirements. This lack of aesthetic flexibility can be problematic for projects requiring a unique visual appearance or matching hinge colors to door designs.

In contrast, options like marine hinges and detachable hinges provide additional customization capabilities, allowing companies to meet specific style or brand aesthetics more effectively.

Unsuitable for Heavy or Exterior Doors

Flush hinges lack the strength needed for exterior or heavy-duty doors, which compromises both security and stability in these applications. Their lightweight construction makes them vulnerable to outdoor elements, which can lead to warping or quicker deterioration if used on exterior doors.

Businesses that need secure, weather-resistant doors, particularly for exterior applications, are often better served by using weld-on hinges or heavy-duty flat hinges that provide the necessary strength for outdoor or load-bearing uses.

Lower Corrosion Resistance

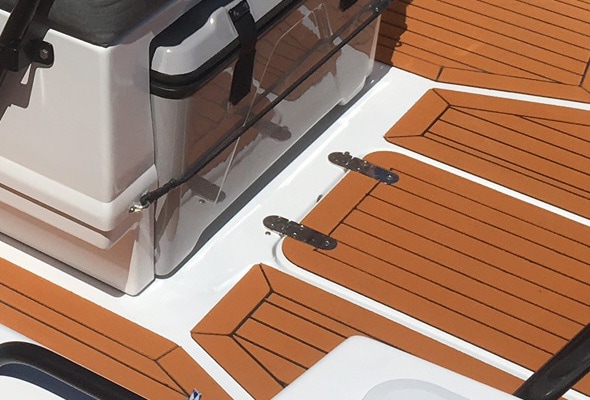

Many flush hinges are not built to withstand high humidity or harsh outdoor conditions, making them prone to rust and corrosion. This issue is especially significant in industries that need long-lasting hinges in variable climates, such as marine and construction sectors.

Compared to flush hinges, Marine Hinges offer higher resistance to moisture and corrosion, providing more durability in environments where exposure to the elements is a primary concern.

Limited Adjustability

Flush hinges have restricted adjustability once installed, unlike more adaptable hinge types that allow for minor modifications after fitting. This lack of adjustability means that any shifting or settling in the door frame can quickly misalign flush hinges, requiring maintenance and creating extra hassle for business operations.

Adjustable hinges, such as climatic test chamber hinges, are often preferable in industrial settings where precise door positioning is essential and frequent readjustments are impractical.

Prone to Warping Under Frequent Use

Frequent use can cause flush hinges to warp or become misaligned, particularly when supporting heavier doors. This limitation impacts their durability in environments with high foot traffic or in commercial applications where reliable, sturdy door operation is essential.

Over time, this tendency to warp under load and frequent use leads to increased repair needs and higher costs. For applications needing more durability, special hinges or cold storage room hinges can provide greater long-term stability and resilience.

Lack of Customization Options

Compared to other hinge types, flush hinges offer fewer customization possibilities, limiting companies’ ability to add branded features, specific functional designs, or unique finishes. This lack of customization can restrict project flexibility and reduce brand consistency for businesses requiring a distinctive or specialized appearance in their hardware.

Using customizable hinges, like trailer door hinges, can provide the flexibility to incorporate company logos or tailored finishes, making them a better fit for businesses aiming for a cohesive brand image.

Limited Compatibility with Heavy-Duty Flat Hinges

Flush hinges struggle in settings where the robust support of heavy-duty flat hinges is required, such as in industrial equipment or large storage units. This limitation makes flush hinges less versatile, particularly in applications where strength and stability are crucial.

For heavier industrial doors or large equipment, heavy-duty hinges and butt hinges are often more compatible options, offering better load distribution and stability.

Conclusion

Flush hinges present several drawbacks, such as limited durability, low weight capacity, and a lack of adjustability, making them unsuitable for high-demand or heavy-duty applications. For projects needing stronger, more versatile hinge solutions, exploring alternatives like heavy-duty and detachable hinges can provide a better fit.